Fiberglass Reinforced Plastic Panel (FRP Roofing Sheets)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Reinforced Plastic Panel (FRP Roofing Sheets)

Description-Fiberglass Reinforced Plastic Panel (FRP Roofing Sheets)

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility.

Today, we’re planning to win more market shares in the world and let more customers know us.

Photos

Product Characters

1. Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

2. Lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%). In this situation, the density of glass fiber reinforced plastic is only about a quarter of the steel.

3. The intensity and stiffness is quite prominent,.

4. Corrosion resistance no rust, no maintenance, long service life.

5. Anti-UV agent are added into all pultrusion FRP profiles get the best anti-uv effect.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

Easy to maintain.

High strength.

Long service life.

Easy to install.

Good light transmittance.

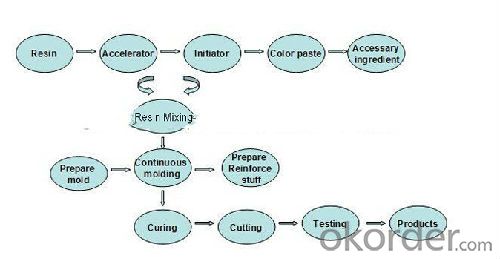

Production Process

Parameters

Density: 1800g/m² 2400g/m² 3050g/m²

Nominal Thickness:0.8mm,1.0mm, 1.2mm 1.5mm 2.0mm, 2.5mm

Heat Resistance Limit: -60 ~ +130

Light Transmittance: 75%±2% ( light green) 53%±2% (cream white)

Anti- ultraviolet Rate: 99.9%

Tensile Strength: 100Mpa

Flexural Strength: 180Mpa

Cracking Elongation Rate: 1.9%

Pasture Hardness: ≥50

Thermal Expansion Coefficient: 2.2×10¯125px/cm/

Thermal Conductivity: 0.18w/m° k

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: Can FRP roofing panels be used for exhibition halls?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for exhibition halls. FRP roofing panels are known for their durability, strength, and resistance to weather elements, making them suitable for various applications, including exhibition halls. They provide excellent protection against UV rays, moisture, and corrosion, ensuring a long-lasting and low-maintenance roofing solution. Additionally, FRP roofing panels are lightweight, allowing for easy installation and reducing the overall load on the building structure. They are also available in a variety of colors and finishes, giving architects and designers the flexibility to create attractive and visually appealing exhibition spaces. Overall, FRP roofing panels are a reliable choice for exhibition halls due to their performance, versatility, and aesthetic qualities.

- Q: How are FRP roofing panels installed?

- FRP (Fiberglass Reinforced Plastic) roofing panels are typically installed in a sequence of steps that ensure a secure and weatherproof installation. Here is a general overview of how FRP roofing panels are installed: 1. Planning and Preparation: Before installation, it is important to thoroughly plan the roofing project. This includes measuring the roof area, ensuring proper flashing and trim materials are available, and acquiring all necessary tools and safety equipment. 2. Safety Measures: Safety should always be a top priority during the installation process. Installers should wear appropriate personal protective equipment (PPE) such as gloves, goggles, and non-slip shoes. Additionally, proper fall protection systems should be in place if working at heights. 3. Roof Surface Preparation: The existing roof surface should be cleaned and cleared of any debris or loose materials. It is important to ensure that the roof is structurally sound and capable of supporting the weight of the FRP panels. 4. Flashing and Trim Installation: Flashing and trim materials are essential for preventing water intrusion and providing a finished appearance. These components are typically installed first, using appropriate fasteners, adhesives, or sealants as recommended by the manufacturer. 5. Panel Layout and Measurement: Before installing the FRP panels, it is important to plan the layout and measure the roof area accurately. This helps to determine the number and size of panels required, ensuring a proper fit and minimizing waste. 6. Panel Installation: FRP panels are installed by positioning them on the roof surface and aligning them according to the predetermined layout. The panels are typically secured using screws or nails, with spacing and fastening methods specified by the manufacturer. It is important to follow the recommended installation guidelines to ensure proper panel alignment, sufficient fastening, and structural integrity. 7. Panel Sealing and Waterproofing: To ensure a watertight roof, it is important to seal the joints and edges of the FRP panels. This is typically done using sealants or adhesives recommended by the manufacturer. Proper sealing prevents water infiltration and protects the underlying roof structure. 8. Finishing Touches: Once the panels are securely installed and sealed, any remaining trim or flashing components are added to complete the installation. These finishing touches provide a clean and professional appearance while enhancing the overall durability of the FRP roofing system. It is important to note that the specific installation process may vary depending on the manufacturer's instructions, the type of FRP panels used, and the unique characteristics of the roof. Therefore, it is recommended to consult the manufacturer's installation guidelines for detailed instructions and best practices. Additionally, it is advisable to hire a professional roofing contractor with experience in FRP roofing installations for a safe and reliable installation process.

- Q: Can FRP roofing panels be used in greenhouses?

- Indeed, greenhouses can utilize FRP (Fiberglass Reinforced Plastic) roofing panels. FRP panels are widely chosen for greenhouse roofs due to their durability, lightweight design, and capacity to allow natural light penetration. Their resistance to weathering and UV radiation makes them highly suitable for environments with prolonged sun exposure. Moreover, FRP panels are effortless to install and require minimal upkeep. The translucency of these panels permits adequate sunlight transmission, fostering robust plant growth, while also providing insulation for temperature regulation and safeguarding plants against harsh weather conditions. In summary, FRP roofing panels present a viable and pragmatic choice for greenhouses.

- Q: Can FRP roofing panels be used in curved or domed roofs?

- FRP roofing panels are capable of being utilized in roofs that are curved or domed. These panels possess a flexible nature, enabling them to be effortlessly molded or shaped to accommodate diverse roof designs, such as curved or domed structures. The pliability of FRP permits it to be bent or curved without compromising its structural integrity. Consequently, FRP roofing panels are an ideal selection for architectural designs necessitating curved or domed roofs. Furthermore, these panels provide exceptional durability, weather resistance, and UV protection, establishing them as a dependable choice for numerous roofing applications.

- Q: Can FRP roofing panels be installed on both residential and commercial buildings?

- FRP roofing panels have the capability to be installed on residential and commercial buildings alike. Their versatility enables usage in multiple applications, including roofing. With their lightweight composition, durability, and exceptional resistance to weathering, UV radiation, and corrosion, FRP roofing panels are an ideal selection for both residential and commercial structures. Furthermore, the availability of FRP panels in diverse colors, shapes, and sizes permits customization to accommodate various architectural styles and design preferences.

- Q: Can FRP roofing panels be used in skylights?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in skylights. FRP panels are lightweight, durable, and resistant to UV rays, making them suitable for skylight applications. They provide excellent light transmission, insulation, and can be custom-made to fit various skylight sizes and shapes.

- Q: Can FRP roofing panels be used for greenhouse roofing?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for greenhouse roofing. FRP panels are durable, lightweight, and have excellent light transmission properties, making them a popular choice for greenhouse construction. They provide UV protection, maintain a stable temperature, and allow optimal light penetration for plant growth. Additionally, FRP panels are resistant to corrosion, chemicals, and weather conditions, making them suitable for long-term use in greenhouse environments.

- Q: Can FRP roofing panels be used for green roofs?

- Yes, FRP (Fiberglass Reinforced Panels) roofing panels can be used for green roofs. Green roofs generally involve the installation of vegetation and growing medium on a rooftop, which can be supported by a variety of roofing materials. FRP roofing panels can provide a suitable base for green roofs, as they offer durability, water resistance, and structural support for the weight of the vegetation and growing medium. However, it is important to ensure proper waterproofing and drainage systems are in place to prevent water leakage and damage to the FRP panels.

- Q: Are FRP roofing panels resistant to warping due to heat?

- FRP roofing panels are renowned for their ability to resist warping caused by heat. These panels are crafted using a blend of fiberglass and plastic resin, resulting in superior structural strength and stability. This unique composition enables FRP panels to endure high temperatures without warping or distorting. They possess a high coefficient of expansion, allowing them to expand and contract without significant effects on their overall shape and integrity. Consequently, FRP roofing panels are especially suitable for regions with extreme heat or fluctuating temperatures. Furthermore, these panels exhibit exceptional thermal insulation properties, further minimizing the impact of heat on them. Overall, FRP roofing panels exhibit remarkable resistance to heat-induced warping, cementing their status as a durable and dependable choice for roofing applications.

- Q: Can FRP roofing panels be used for parking structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for parking structures. FRP panels are known for their durability, lightweight nature, and resistance to corrosion, making them suitable for various applications, including parking structures. They offer excellent protection against weather elements, are easy to install and maintain, and can provide sufficient natural lighting. Additionally, FRP panels can be customized to meet specific design requirements, making them a versatile choice for parking structures.

Send your message to us

Fiberglass Reinforced Plastic Panel (FRP Roofing Sheets)

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 kg

- Supply Capability:

- 200000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords