Fiberglass Corrugated Roofing Sheet Used in Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions.

FEATURES

1). Light Transmission: The light transmission of FRP roof sheet is between 3%-85%. Light through FRP corrugated sheet scatters and is mild. It will not form a light so as to make the indoor brighter.

2). Weather resistant: The UV agent mixing in the corrugated sheet, which can truly resist the damage of ultraviolet ray, which can truly resist the damage of ultraviolet ray.

3). Flame retardant: B1 grade.

4). Anti-corrosion: It resists chemical corrosion and its life span is over 3 times longer than zinc panel.

5). Water proof:100% water proof.

6). Impact capacity: resist impact, tensile and hardly breakable.

7). Light weight: the weight is light, etc

SPECIFICATIONS

Composition | UP-resin system, glass fiber , gel coat or protective film |

Surface | Dupon 20um Film or Gel Coat |

Fiber Content | 25% - 35%, using JUSHI fiber |

Thickness | 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 2.5mm, 3.0mm, 3.5mm, 4.0mm |

Width | Up to 1.35 meter |

Effective temperature | -40℃~ +120℃ |

Light Transmissivity | 3% - 85% |

Length | Customizable, for easy transport, suggest using 5.6m or 11.8m |

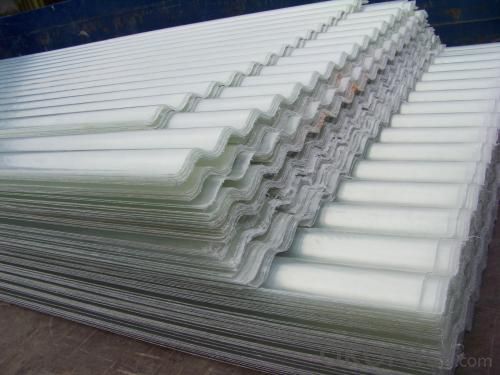

Profile | Flat type & corrugated type, LG840, LG900, LG1050 or customizable |

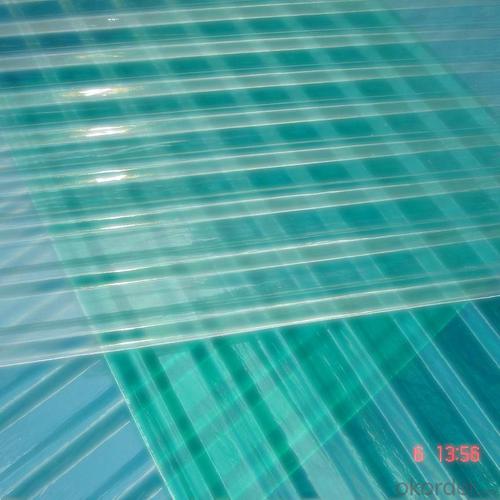

Colors | Clear blue, Light blue, Lake blue, Sky blue, Deep blue, Clear white, Solid white, Gray white, Black, Clear green or Customizable |

PICTURES

- Q: Are FRP roofing panels suitable for restaurants?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for restaurants. FRP panels have several features that make them a great choice for restaurant roofs. Firstly, FRP panels are highly durable and resistant to harsh weather conditions, such as extreme temperatures, UV rays, and moisture. This is particularly important for restaurants as they often have outdoor seating areas or rooftop sections that need protection from the elements. Secondly, FRP panels are lightweight, which makes them easy to install and reduces the load on the building structure. This is advantageous for restaurants as it minimizes the need for additional structural support and lowers installation costs. Furthermore, FRP panels are known for their excellent thermal insulation properties. This means that they can help maintain a comfortable indoor temperature, reducing the need for excessive air conditioning or heating. This can result in energy savings and lower utility bills for the restaurant. Additionally, FRP panels are fire-resistant, which is crucial for commercial establishments like restaurants that have a higher risk of fire hazards due to cooking activities and the presence of flammable materials. Lastly, FRP panels come in a variety of colors and finishes, allowing restaurants to choose a design that matches their aesthetic preferences. Overall, FRP roofing panels are a suitable choice for restaurants due to their durability, weather resistance, lightweight nature, thermal insulation properties, fire resistance, and versatility in design options.

- Q: Can FRP roofing panels be used for zoos?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for zoos. FRP panels are highly durable, weather-resistant, and have excellent strength-to-weight ratio, making them suitable for various applications including zoos. These panels can provide reliable protection for animals and withstand harsh environmental conditions while also allowing natural light to pass through, creating a comfortable and visually appealing environment for both animals and visitors.

- Q: Can FRP roofing panels be used in shopping malls or retail centers?

- FRP roofing panels are perfectly suitable for shopping malls or retail centers. These panels are renowned for their durability, versatility, and resistance against corrosion, which makes them ideal for various commercial applications. Moreover, their lightweight nature facilitates easy and cost-effective installation. In addition, FRP roofing panels come in a wide array of colors and finishes, allowing seamless integration with the design and aesthetic of shopping malls or retail centers. These panels also boast excellent natural light transmission, minimizing the need for artificial lighting during daylight hours and potentially reducing energy expenses. In summary, FRP roofing panels are an excellent choice for shopping malls or retail centers due to their durability, versatility, and aesthetic appeal.

- Q: Are FRP roofing panels suitable for both residential and commercial buildings?

- FRP roofing panels are appropriate for both residential and commercial buildings due to their numerous advantages. Firstly, these panels are lightweight yet incredibly durable, making them a viable option for various building types. Regardless of whether it is a small residential house or a large commercial structure, FRP panels can provide dependable and long-lasting roofing solutions. Moreover, FRP panels exhibit exceptional resistance against corrosion, UV rays, and weathering. Consequently, they are particularly suitable for both residential and commercial buildings as they can endure harsh environmental conditions while maintaining their structural integrity over time. Whether it is exposure to severe weather or the requirement for long-term durability, FRP roofing panels can meet the challenge. Furthermore, FRP panels possess versatility and can be tailored to meet the specific needs of residential and commercial buildings. They are available in different sizes, colors, and designs, allowing for flexibility in architectural aesthetics. Additionally, the installation of FRP panels is straightforward, reducing the time and cost associated with roofing projects. Concerning energy efficiency, FRP panels can contribute to reducing energy consumption in both residential and commercial buildings. Their insulation properties aid in regulating temperature, minimizing the need for excessive heating or cooling. This leads to energy savings and enhanced comfort levels for occupants. In conclusion, FRP roofing panels are an appropriate choice for both residential and commercial buildings. Their lightweight yet durable nature, resistance to corrosion and weathering, versatility, and energy efficiency properties make them an outstanding option for various roofing applications.

- Q: Can FRP roofing panels be used for both new construction and roof replacements?

- Yes, FRP roofing panels can be used for both new construction and roof replacements. FRP panels are versatile and can be easily installed on various types of roofs, making them suitable for both new buildings and existing structures in need of a roof replacement.

- Q: Can FRP roofing panels be installed on both residential and commercial loading docks?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on both residential and commercial loading docks. FRP roofing panels are a popular choice for loading docks due to their durability, lightweight nature, and resistance to corrosion and weathering. They are suitable for both residential and commercial applications as they provide a strong and stable roofing solution. Additionally, FRP roofing panels are easy to install, making them a convenient choice for loading docks of various sizes and types. Whether it is a residential loading dock or a commercial one, FRP roofing panels can be effectively installed to provide reliable protection and longevity.

- Q: Do FRP roofing panels require a specific type of flashing tape?

- Yes, FRP roofing panels typically require a specific type of flashing tape that is compatible with the materials used in the panels. The flashing tape should be chosen based on the specific requirements of the FRP panels to ensure proper installation and long-term durability.

- Q: Are FRP roofing panels suitable for residential garages or carports?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for residential garages or carports. FRP panels are lightweight, durable, and have excellent resistance to weathering, UV rays, and impact. They provide a long-lasting roofing solution that requires minimal maintenance. Additionally, FRP panels are available in various colors and profiles, allowing homeowners to choose a design that matches their aesthetic preferences. The installation process of FRP panels is relatively straightforward, making them a practical choice for DIY enthusiasts. Overall, FRP roofing panels offer a cost-effective and reliable option for residential garages or carports.

- Q: Can FRP roofing panels be used for skylights or atriums?

- FRP roofing panels are indeed suitable for skylights or atriums. Their durability, strength, and versatility are well-known, making them a great choice for various applications, including skylights and atriums. These panels are lightweight, yet they offer excellent resistance against impact, UV rays, and harsh weather conditions. They can be designed to let natural light pass through while still providing insulation and protection. Moreover, FRP panels come in different colors, profiles, and sizes, allowing for customization to meet the specific requirements of skylights or atriums. All in all, FRP roofing panels are widely favored for these applications due to their durability, appealing appearance, and ability to effectively transmit natural light.

- Q: Are FRP roofing panels suitable for outdoor entertainment areas or patios?

- Yes, FRP roofing panels are suitable for outdoor entertainment areas or patios. FRP, or fiberglass reinforced plastic, roofing panels are highly durable, weather-resistant, and provide excellent protection against UV rays. They can withstand various outdoor elements such as rain, wind, and sunlight, making them ideal for outdoor spaces like patios or entertainment areas. Additionally, FRP panels are lightweight, easy to install, and require minimal maintenance, making them a practical choice for enhancing outdoor spaces while ensuring long-lasting performance.

Send your message to us

Fiberglass Corrugated Roofing Sheet Used in Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords