3M Damping Aluminum Foam Sheets 4014 - Five Bar Treadplate Aluminium Panel 3003 H22 for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Five Bar Treadplate Aluminium Panel 3003 H22 for Tool Box

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Five Bar Treadplate Aluminium Panel 3003 H22 for Tool Box

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Five Bar Treadplate Aluminium Panel 3003 H22 for Tool Box

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

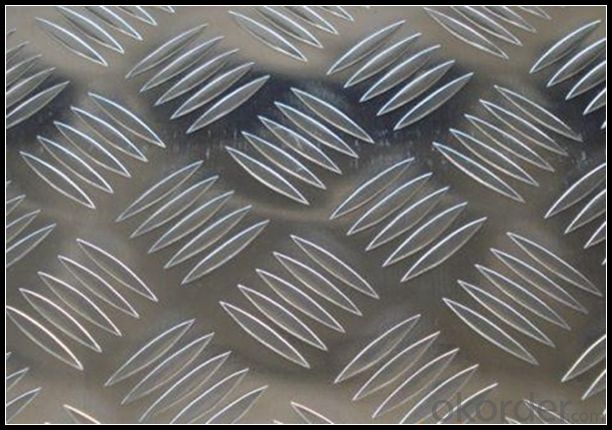

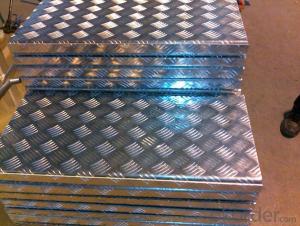

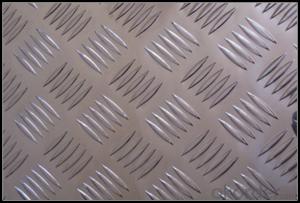

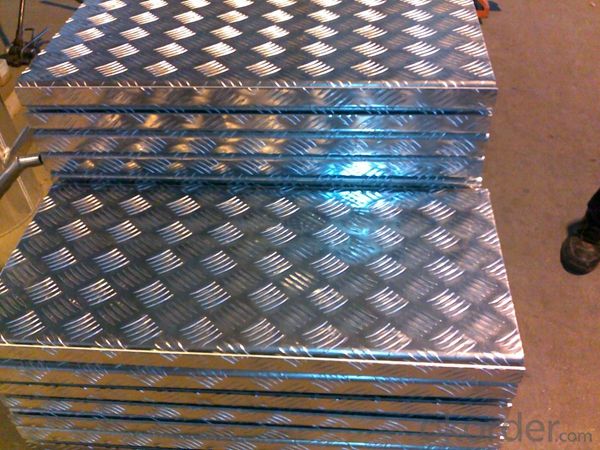

5. Image of Five Bar Treadplate Aluminium Panel 3003 H22 for Tool Box

6. Package and shipping of Five Bar Treadplate Aluminium Panel 3003 H22 for Tool Box

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheets be used for packaging purposes?

- Yes, aluminum sheets can be used for packaging purposes. They are commonly used in the packaging industry due to their lightweight, corrosion-resistant, and malleable properties. Aluminum sheets can be easily formed into various shapes and sizes, making them ideal for packaging products such as food, beverages, pharmaceuticals, and cosmetics. Additionally, aluminum provides a protective barrier against moisture, oxygen, and light, ensuring the quality and longevity of the packaged goods.

- Q: What are the different methods of bending aluminum sheets?

- There are several methods of bending aluminum sheets, each with its own advantages and limitations. Some of the commonly used methods include: 1. Press Brake Bending: This method involves clamping the aluminum sheet between a punch and a die on a press brake machine. The sheet is then bent by applying force through the punch, which pushes against the die. Press brake bending is ideal for high-volume production and can achieve precise and consistent bends. 2. Roll Bending: Also known as a three-roll bending process, this method uses a set of three rollers to gradually bend the aluminum sheet into the desired shape. Roll bending is suitable for creating cylindrical or conical shapes and is often used in industries like automotive and aerospace. 3. Stretch Bending: In this method, the aluminum sheet is clamped at both ends while a stretching force is applied in the middle. The sheet is elongated and bent simultaneously, resulting in a curved shape. Stretch bending is commonly used for producing curved profiles with a smooth and uniform finish. 4. Heat Bending: By applying heat to the aluminum sheet, it becomes more pliable and can be easily bent into desired shapes. Heat bending is often performed using a heat gun or an oven to soften the metal, followed by manual or mechanical bending. This method is useful for creating complex and intricate shapes. 5. Incremental Bending: This method involves bending the aluminum sheet in multiple steps or increments, gradually increasing the bend angle with each step. Incremental bending allows for greater control over the bending process and is commonly used for forming U-shaped or V-shaped bends. 6. Roll Forming: In roll forming, the aluminum sheet is fed through a series of rollers, each gradually bending the sheet a little more. This continuous process is ideal for producing long and consistent bends, often used in the production of aluminum profiles and extrusions. It is worth noting that the choice of bending method depends on factors like the desired bend angle, the thickness and grade of the aluminum sheet, the required precision, and the volume of production.

- Q: Can aluminum sheets be anodized for aesthetic purposes?

- Aluminum sheets have the ability to undergo anodization for the purpose of aesthetics. Anodization is an electrochemical procedure that forms a protective oxide layer on the surface of the aluminum. This layer has the potential to be colored in a variety of shades, thus offering a wide range of aesthetic possibilities. Anodized aluminum sheets are highly sought after in the field of architecture, particularly for constructing facades, due to their enduring and visually pleasing appearance. Furthermore, the anodized layer bolsters the aluminum's resistance to corrosion and wear, making it suitable for both indoor and outdoor applications. Moreover, anodized aluminum sheets can be subjected to additional processes like etching or laser engraving, enabling the creation of intricate designs and patterns.

- Q: What are the different methods of surface protection for outdoor aluminum sheet?

- There are several methods of surface protection for outdoor aluminum sheets. One common method is painting the surface with a protective coating, such as a weather-resistant paint or powder coating. Another method is anodizing, which involves creating a durable oxide layer on the surface of the aluminum. Additionally, applying a clear protective film or using a protective sealant can also help protect the aluminum sheet from outdoor elements.

- Q: Can the aluminum sheets be bent or formed into different shapes?

- Yes, aluminum sheets can be easily bent or formed into different shapes. Aluminum is a highly malleable metal, meaning it can be easily manipulated without breaking or cracking. This property makes it ideal for various applications where flexibility and customization are required. Aluminum sheets can be bent, folded, rolled, or formed using a variety of techniques such as press brakes, rollers, or specialized forming tools. This versatility allows for the creation of complex shapes and structures, making aluminum a popular choice in industries like construction, automotive, aerospace, and manufacturing.

- Q: What is the classification of 6061106070 aluminum plate, which respectively represent what it means to ask God for help

- The six is the beginning of aluminum silicon alloy is 6061, the United States, 6063, 6082, (a less plate plate is also in many aspects at the beginning of the seven section), is al mg Zn Cu alloy, 7075, 7050, 7475, also belong to the aviation aluminum, also called super hard at the beginning of the eight other series, is currently used in many aspects of the cap, usually thin. As for the number of each brand on behalf of what meaning, I answered another netizen's questions, you know in Baidu search "aluminum plate 1060-H24 what does it mean", you can see my answer

- Q: The idea that you can adequately protect yourself from the Alien and government thought transmissions with a 'tin-foil / aluminum hat is just a myth. The correct and real thing to use is an aluminum construction site type of hard-hat. That is why the government and all major defense contractors wore aluminum hard-hats back in the 1950's. The plastic and fiber glass hard-hats that they use now is only because the Aliens got wise to the old aluminum hard-hat trick and outlawed them after the Aliens and their Illuminati minions took over after President Truman got out of office. Everyone knows that.So does any company anywhere in the world currently defy the Alien’s production ban on aluminum hard hats? Or is e-bay and garage sales the only source of aluminum construction site hard hats?

- what's ENMOD we ask with baited breath ... lets find out ... Excluded from the Copenhagen Agenda: Environmental Modification Techniques (ENMOD) and Climate Change The manipulation of climate for military use ... man I could be a great nutter ...I missed my calling ...

- Q: Can the aluminum sheets be used in marine environments?

- Yes, aluminum sheets can be used in marine environments. Aluminum is a popular choice for marine applications due to its excellent corrosion resistance. Unlike other metals, aluminum forms a protective oxide layer on its surface when exposed to oxygen, preventing further corrosion. This makes it ideal for use in saltwater environments where the risk of rusting and corrosion is high. Additionally, aluminum is lightweight, durable, and has a high strength-to-weight ratio, making it suitable for various marine applications such as boat hulls, shipbuilding, offshore platforms, and other marine structures.

- Q: Can aluminum sheets be used for food display cases?

- Yes, aluminum sheets can be used for food display cases. Aluminum is a common material used in the food industry due to its durability, light weight, and resistance to corrosion. It is also easy to clean and maintain, making it suitable for displaying food in a hygienic and visually appealing way.

- Q: Can aluminum sheets be waterjet cut?

- Indeed, it is possible to employ waterjet cutting for aluminum sheets. By utilizing a combination of high-pressure water and an abrasive substance, waterjet cutting proves to be an adaptable approach in severing a range of materials, including aluminum and other metals. The efficacy of this technique in cutting aluminum stems from its ability to avoid heat generation, thereby preventing potential distortion or harm to the metal. Moreover, it ensures exceptional precision and accuracy, facilitating the effortless cutting of intricate shapes and designs. Consequently, waterjet cutting has become a prevalent practice in industries necessitating immaculate and precise cuts in aluminum sheets, such as aerospace, automotive, and manufacturing.

Send your message to us

3M Damping Aluminum Foam Sheets 4014 - Five Bar Treadplate Aluminium Panel 3003 H22 for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords