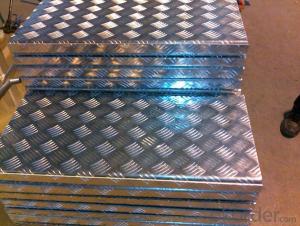

Light Gauge Aluminum Sheets - Five Bars Aluminium Checkered Plate for Truck Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Five Bars Aluminium Checkered Plate for Truck Tool Box

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Five Bars Aluminium Checkered Plate for Truck Tool Box

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Five Bars Aluminium Checkered Plate for Truck Tool Box

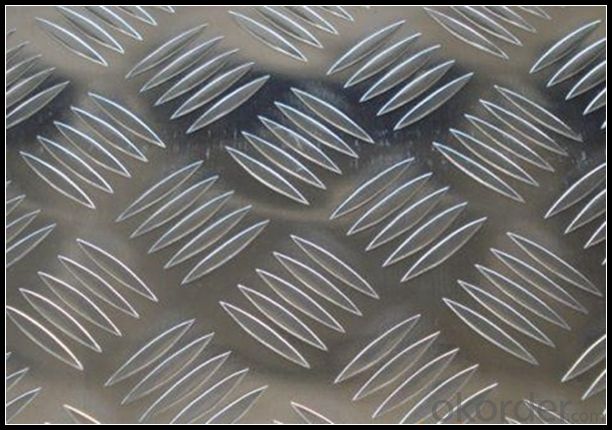

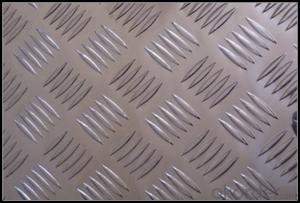

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

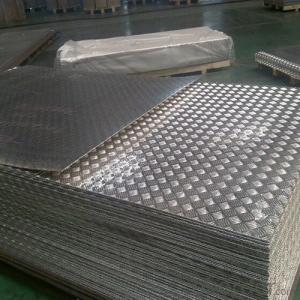

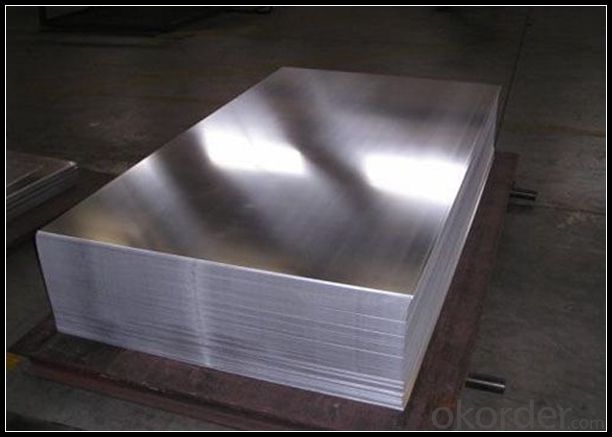

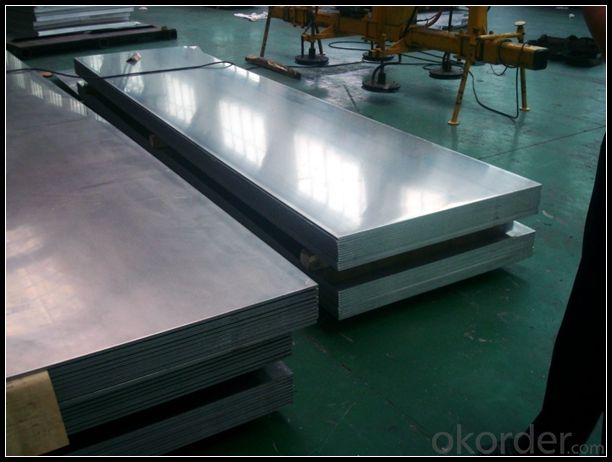

5. Image of Five Bars Aluminium Checkered Plate for Truck Tool Box

6. Package and shipping of Five Bars Aluminium Checkered Plate for Truck Tool Box

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can 101 aluminum sheets be used in the production of musical instruments?

- Yes, 101 aluminum sheets can be used in the production of musical instruments. They offer good conductivity and durability, making them suitable for various components like instrument bodies, panels, or parts that require lightweight construction.

- Q: This question asks for a comparison between aluminum sheets and other roofing materials in terms of their characteristics and performance.

- <p>Aluminum sheets are lightweight and highly durable, offering excellent resistance to corrosion and weathering. They are energy-efficient, reflecting heat and reducing cooling costs. Compared to materials like asphalt shingles, aluminum is more expensive but lasts longer, with a lifespan of 40-50 years. Unlike clay or concrete tiles, aluminum is less prone to breakage and is easier to install. It also doesn't rot or warp like wood, and it's fire-resistant. However, it can be noisy during rain and is less visually appealing than some other materials, but its modern and sleek appearance can be a design advantage.</p>

- Q: How to distinguish fluorocarbon spraying and powder spraying aluminium plate

- 1. Identification of fluorocarbon spraying and powder spraying aluminum plate:(1) measuring thickness, fluorocarbon three coated with 40UM, and powder coating at least 60UM.(2) surface evenness, fluorocarbon is generally paint, surface smoothness is higher, leveling is better. The powder spraying has poor flatness. Orange peel phenomenon is obvious.(3) look at the back of the workpiece. The back of the workpiece in the transition area of powder coating spraying and spraying, obviously rude sense. And paint is better.(4), the experiment, with a knife or about 400 mesh sandpaper graze back coating, causes the inclined fault. If there are different colors, then fluorocarbon (if not found, you can use a magnifying glass).

- Q: What are the different methods of joining aluminum sheets without welding?

- There are several methods of joining aluminum sheets without welding, including adhesive bonding, mechanical fastening (such as screws or rivets), clinching, and using non-welding techniques like friction stir welding or laser welding.

- Q: Can aluminum sheets be laminated?

- Yes, aluminum sheets can be laminated. Lamination is a process of bonding multiple layers together to create a composite material with enhanced properties. In the case of aluminum sheets, they can be laminated with other materials such as plastics, adhesives, or even other metals. This process can improve the strength, durability, and thermal or electrical conductivity of the aluminum sheets. Laminated aluminum sheets are commonly used in various industries, including construction, automotive, aerospace, and packaging, where the combination of different materials provides the desired characteristics for specific applications.

- Q: Can aluminum sheets be used for electrical conductors?

- Yes, aluminum sheets can be used for electrical conductors. Aluminum is a good conductor of electricity and is commonly used in various electrical applications such as wiring, cables, and power transmission lines.

- Q: Can aluminum sheets be an alternative to stainless steel?

- Yes, aluminum sheets can be an alternative to stainless steel in certain applications. Aluminum is generally lighter, more affordable, and has better thermal conductivity compared to stainless steel. However, stainless steel offers superior corrosion resistance and strength, making it more suitable for certain industries like food processing or marine environments. The choice between aluminum and stainless steel depends on the specific requirements and constraints of the project.

- Q: combines with oxygen with an atomic weight of 16, to form the compound aluminum oxide, how much oxygen would be required to react completely with 54g of aluminum?

- Well, Al2O3 is the formula for aluminum oxide So you have 2 moles of Al, so you need 3 moles of O which is 1.5 moles of O2 So the answer is 48g

- Q: Can the aluminum sheets be used for manufacturing door frames?

- Yes, aluminum sheets can be used for manufacturing door frames.

- Q: What are some common applications of aluminum sheets?

- Aluminum sheets have a wide range of applications due to their unique properties. Some common applications of aluminum sheets include: 1. Construction: Aluminum sheets are commonly used in the construction industry for roofing, siding, and window frames. Their lightweight nature and durability make them an ideal choice for these applications. 2. Automotive industry: Aluminum sheets are extensively used in the automotive industry to manufacture car bodies, panels, and components. The lightweight nature of aluminum helps reduce the overall weight of vehicles, leading to improved fuel efficiency. 3. Packaging: Aluminum sheets are commonly used for packaging purposes, especially in the food and beverage industry. They are used to make cans, foils, and lids, thanks to their ability to preserve the freshness and quality of the packaged products. 4. Aerospace industry: Aluminum sheets play a vital role in the aerospace industry. They are used to manufacture aircraft bodies, wings, and structural components due to their high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. 5. Electrical industry: Aluminum sheets are used in the electrical industry for various applications, including manufacturing electrical enclosures, transformers, and bus bars. Aluminum's excellent conductivity and lightweight nature make it a preferred choice for these applications. 6. Marine industry: Aluminum sheets are widely used in the marine industry for building boats, ship hulls, and other marine structures. Aluminum's resistance to corrosion and its ability to withstand harsh marine environments make it a suitable material for these applications. 7. Decorative purposes: Aluminum sheets are frequently used for decorative purposes in architecture and interior design. They can be shaped, engraved, or coated with different finishes to create aesthetically pleasing surfaces for walls, ceilings, furniture, and signage. These are just a few examples of the common applications of aluminum sheets. The versatility, durability, and lightweight nature of aluminum make it a highly sought-after material in various industries.

Send your message to us

Light Gauge Aluminum Sheets - Five Bars Aluminium Checkered Plate for Truck Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords