Aluminum Foil Sheets Five Bar Treadplate Aluminium Panel for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Five Bar Treadplate Aluminium Panel for Tool Box

Alloy Number | AA1XXX,AA3XXX,AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

2. Application of Five Bar Treadplate Aluminium Panel for Tool Box

Transfporation, vehicle, antiskid plate,toolbox,canopy body,

3. Feature of Five Bar Treadplate Aluminium Panel for Tool Box

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

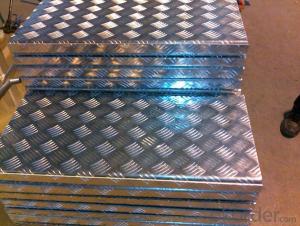

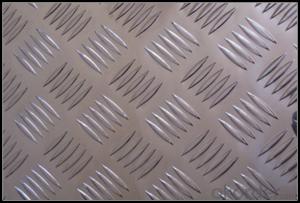

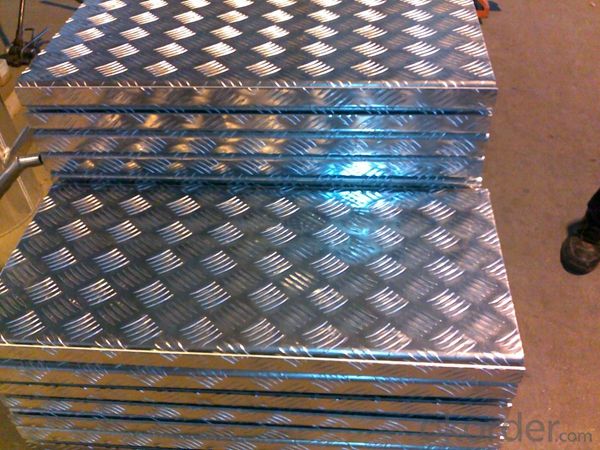

5. Image of Five Bar Treadplate Aluminium Panel for Tool Box

6. Package and shipping of Five Bar Treadplate Aluminium Panel for Tool Box

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheets be used for sound barriers?

- Indeed, sound barriers can be created using aluminum sheets. Aluminum, being a lightweight and durable material, has the ability to effectively block and absorb sound waves. This quality makes it an excellent option for soundproofing purposes. Aluminum sheets can be utilized in various ways, such as solid panels or perforated sheets, to establish efficient sound barriers in residential, commercial, and industrial settings. The thickness and design of the aluminum sheets are customizable to meet specific soundproofing needs. Moreover, aluminum is resistant to corrosion, rendering it suitable for outdoor applications where sound barriers may be exposed to harsh weather conditions. In summary, aluminum sheets offer an economical and effective solution for reducing noise levels and establishing quieter surroundings.

- Q: How do you ensure the surface quality of aluminum sheets?

- To guarantee the surface quality of aluminum sheets, manufacturers can take several steps: 1. Cleanliness is crucial. Prior to any surface treatment or inspection, it is vital to thoroughly clean the aluminum sheets and eliminate any dirt, grease, or contaminants. This can be accomplished using solvents, detergents, or specialized cleaning agents. 2. A visual inspection is necessary. Trained personnel should visually inspect the surface for visible flaws such as scratches, dents, or pitting. Proper lighting and magnification tools should be utilized. 3. Chemical treatments may be required. Depending on the desired surface finish and application, aluminum sheets may undergo chemical treatments such as anodizing, chromate conversion coating, or passivation. These processes can enhance the sheets' surface quality, corrosion resistance, and aesthetic appearance. 4. Mechanical polishing can be employed. To eliminate surface imperfections and achieve a smooth, glossy finish, mechanical polishing techniques like grinding, buffing, or sanding can be utilized. It is important to maintain consistency and avoid over-polishing, which can compromise the integrity of the sheets. 5. Coating and protection are essential. Applying protective coatings like lacquers, paints, or powder coatings can further improve the surface quality, appearance, and durability of aluminum sheets. These coatings act as a barrier against corrosion, abrasion, and environmental factors. 6. Quality control is crucial. Rigorous quality control procedures should be implemented throughout the manufacturing process. Regular inspections, testing, and documentation should be conducted to ensure that the surface quality of aluminum sheets meets the required standards and specifications. 7. Proper handling and packaging are necessary. To prevent surface damage during transportation and storage, it is important to handle and package the sheets correctly. Protective measures such as using protective films, paper interleaves, or cushioning materials should be employed to safeguard the surface quality until the sheets reach their final destination. By following these measures, manufacturers can ensure that the surface quality of aluminum sheets meets the desired specifications and exceeds customer expectations.

- Q: Aluminum plate thickness 1 cm, iron plate thickness 0.15 cm, area 1 square meters, thank you

- It's too difficult. Just think about it

- Q: Can 101 aluminum sheets be customized in terms of size and thickness?

- Certainly! It is possible to customize the size and thickness of 101 aluminum sheets. One can achieve the desired size and thickness by employing diverse cutting methods like shearing, sawing, or laser cutting. Moreover, rolling or stretching the aluminum sheets can also result in the desired thickness. By personalizing the size and thickness of aluminum sheets, they can be tailored to meet specific applications or requirements.

- Q: what is better for my 96 mustang gt. porting and polishing my stock heads or getting aluminum heads. also could i do a 3v conversion?

- It is hard to beat a set of CNC machined new heads. By the time you pay the machining amd parts cost you may be money ahead to buy the new heads.

- Q: How do aluminum sheets perform in high-temperature environments?

- Aluminum sheets generally perform well in high-temperature environments due to their excellent thermal conductivity and high melting point. They can withstand elevated temperatures without significant deformation or loss of structural integrity. However, at extremely high temperatures, aluminum may experience some oxidation or corrosion, which can affect its performance.

- Q: This question asks for a guide on the correct procedure to install aluminum sheets, likely for construction or renovation purposes.

- <p>To install aluminum sheets properly, follow these steps: 1. Prepare the surface by cleaning and leveling it. 2. Measure and cut the aluminum sheets to the required size using a metal saw or tin snips. 3. Apply a bead of construction adhesive along the edges of the surface where the sheets will be placed. 4. Position the aluminum sheet, ensuring it's aligned correctly. 5. Secure the sheet with screws or nails, using a washer to prevent tearing. 6. Seal the seams and edges with a weatherproof sealant to prevent water ingress. 7. Inspect the installation for any gaps or unevenness and make adjustments as needed. Always follow the manufacturer's guidelines and safety precautions while working with aluminum sheets.</p>

- Q: Are aluminum sheets suitable for architectural canopies?

- Architectural canopies can indeed be made using aluminum sheets. Aluminum is a popular material choice for architectural applications because of its lightweight nature, durability, and flexibility. It possesses a high strength-to-weight ratio, making it capable of enduring various weather conditions and providing stability for canopies. Moreover, aluminum is highly resistant to corrosion, ensuring that the architectural canopy remains visually appealing and functional for an extended period. Its malleability allows for easy fabrication and customization, enabling architects and designers to create unique and intricate canopy designs. Additionally, aluminum is an environmentally friendly option as it can be recycled, contributing to sustainable construction practices. All in all, aluminum sheets are a dependable and versatile choice for architectural canopies.

- Q: Can aluminum sheets be used in aerospace industry?

- Yes, aluminum sheets can be used in the aerospace industry. Aluminum is a commonly used material due to its lightweight properties, high strength-to-weight ratio, and excellent corrosion resistance. It is used in various components of aircraft such as wings, fuselage, and structural parts.

- Q: Can aluminum sheet be used for automotive applications?

- Yes, aluminum sheet can be used for automotive applications. It is commonly used in the manufacturing of car bodies, hoods, doors, and other structural components due to its lightweight, corrosion resistance, and high strength-to-weight ratio.

Send your message to us

Aluminum Foil Sheets Five Bar Treadplate Aluminium Panel for Tool Box

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords