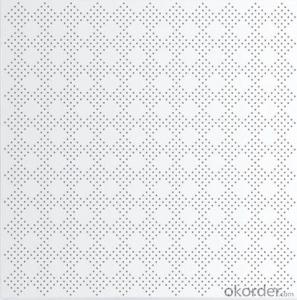

Fiberglass Wall Panels Ceiling Acoustic Fabric Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

fiberglass ceiling is made from sound absorbing plate of fiberglass wool/Rock wool as basis material and on it compound sprayed fiberglass decorative felt. It features good sound absorbing effect, heat preservation, high fire retardant, high strength level , beautiful decorative effect, etc. it can improve acoustical environment of building and raise peoples quality of work and living. It is widely used for indoor space where not only has the requirement to drop noise but also the needs medium and high quality decoration, such as hospital, meeting room, exhibition hall, cinema, library ,studio, gymnasium , phonetic classroom, shopping place ,etc.

Product Applications:

The panels are udes widely in schools, offices, music studios, lecture theatres,

multi purpose halls, interview rooms, training areas and cinemas. They meet the

requirements of BB93 of Building Regulations for acoustics in school buildings and

are Class O fire rated hence meeting the Fire Regulations as well.

Product Advantages:

Saves headroom space because exceptional noise absorption effectiveness is achieved by low (30mm) material thickness.

Surfaces can be emulsion painted to any colour without significant loss in noise

absorption. Increase savings due to fast and easy installation.Lightweight and therefore are ideal for adhering to ceilings, which do not have a very high load bearing capabilities.

Meets BB93 standards for school acoustics as well as common areas in flats for Building

Regulations.

Reinforced edges for increased durability.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q: Waterproof acceptance how to accept kitchen and toilet waterproof is done?

- Hope to help you get, feel good, please accept Thank you! Fireproof materials are mainly non-combustible materials and B1 grade flame retardant materials. Class A Noncombustible Material: Granite, marble, terrazzo, cement products, concrete products, gypsum board, lime products, clay products, glass, tiles, mosaic, steel, aluminum, copper alloy; B1 grade flame retardant material: Plastic materials, gypsum board, fiber gypsum board, cement particle board, mineral wool decorative sound absorption board, glass wool decorative sound absorption board, perlite decorative sound absorption board, flame retardant plywood, flame retardant medium density fiberboard, rock wool decorative panels, Flame retardant wood, aluminum foil composite materials, flame retardant phenolic plywood, aluminum foil glass fiber reinforced plastic composite materials; Wall material gypsum board, fiber gypsum board, cement particle board, mineral wool board, glass wool board, perlite board, flame retardant plywood, flame retardant medium density fiberboard, fire plastic decorative panels, flame retardant double-sided particleboard, colorful paint , Flame retardant wall paper, fire-resistant imitation granite decorative plate, magnesium chloride cement assembly wallboard, flame retardant glass steel plate, PVC plastic wall panels, light high-strength composite wall panels, flame-retardant molded wood composite sheet , Color flame retardant wood-based panels, flame retardant glass and steel

- Q: Melamine plastic synthesis process, mainly the molding powder added in that process

- There are many types of plastic products, a lot of classification methods.

- Q: How is the basement corridor decoration better? How is the noise treatment better?

- Villa basement decoration Note how much to know how much light the sun is often the basement is expected to be unsustainable.

- Q: Epoxy resin when the ratio of curing agent than the high proportion of what impact? What is the impact of low. What is the reason for hardening after curing?

- Curing agent will increase the speed of curing more, put less curing time will be slower. But do not be higher or lower too much, whether it is more or less, excessive will appear false curing. That is what you said after curing is not hard

- Q: There are a lot of wires and tubing between the joists and I'm not sure if I'm supposed to work the insulation around them or just lay the stuff over it. Seems like if there was a problem with the water or electricity, finding the wires and such would become a problem with them tucked under the insulation. Any help would be greatly appreciated.

- one thing you didnt mention is why you want to insulate a basement ceiling. i can understand if its for sound abaitment but insulating a basement ceiling isnt really necessary (unless ofcourse its required by local code). in answer to your question, you tuck the insulation around wires and piple by pulling the insulation apart. compressing the insulation against wires and pipes compromises its effectiveness. heres what i would do. instead of fiber glass insulation use what is called sound board (it has thermal qualitys as well) and then sheet rock over that. sound board (it used to be call celetex back in the day) is available at home depot and most lumber yards.

- Q: Magnesium chloride crystal structure and detailed solution

- From the magnesium chloride crystals 4.06 g 1.9 g anhydrous magnesium chloride, the mass of the crystal water in the magnesium chloride crystals was 4.06 g-1.9 g = 2.16 g 2.16 ÷ 18 = 0.12 mol The amount of MgCl2 was 0.02 mol. It was found that 0.12 ÷ 0.02 = 6 Magnesium chloride crystals in the crystal water is 6 times the amount of Mgcl2 so n = 6 Chemical formula for Mgcl2 · 6H2O

- Q: We have removed our rough sawn cedar from our cathedral ceiling in our 80's home. We found fiberglass insulation and 2x6 joists (the roof is directly above). The first electrician came out before we removed the ceiling and assumed there was no insulation and said we needed to get spray insulation because of the condensation can lights can cause. The other electrician we called out came after we removed the ceiling and did not say anything about condensation. Neither said anything about ice dams. I am seeing all this pretty scary stuff when doing my research, and am thinking we shouldn't put in recessed lighting now! We live in Wyoming where the climate can be pretty cold, but is usually very dry.So, if we use LED lamps and IC airtight housings, will the heat transfer really be bad enough to cause condensation and/or ice dams? Would it help to put some foam board between the shallow housings and the roofing substrate (if it fits)? We are only planning on putting up 6 6&quot; lights in a 10x20 room...

- You have to get the right kind of lights. LED lights don't get all that hot, but unless they're made for zero clearance, yes they do need some airspace around them. They make some with no need for airspace around them. They have an additional can around them to allow the space they need. Get the right kind, no problems, get the wrong kind, lots of problems.

- Q: New home decoration is the choice of all-inclusive or half-pack good?

- All-inclusive peace of mind half-bag assured if you choose the whole package recommended the use of materials and specifications in parallel into the contract if the choice of semi-package to run the market do not easily meet the gold than the three do not suffer to the seller to obtain quality assurance

- Q: What is the relationship between the two? Or who is engaged in the electronics industry, can give me talk about the industry's industrial chain and technical process? Thank you.

- Glass fiber is an excellent inorganic nonmetallic material. English formerly known as: glass fiber or fiberglass. Ingredients are silica, alumina, calcium oxide, boron oxide, magnesium oxide, sodium oxide and the like. It is a glass ball or waste glass as raw material by high temperature melting, drawing, yarn, weaving and other technology. And finally the formation of various types of products, glass fiber monofilament diameter from a few microns to twenty meters a few microns, equivalent to a hair of 1 / 20-1 / 5, each bundle of fiber raw silk has hundreds or even Thousands of single-wire composition, usually as a composite material in the reinforcement materials, electrical insulation materials and insulation materials, circuit boards, widely used in various areas of the national economy.

Send your message to us

Fiberglass Wall Panels Ceiling Acoustic Fabric Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords