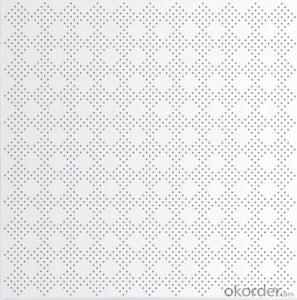

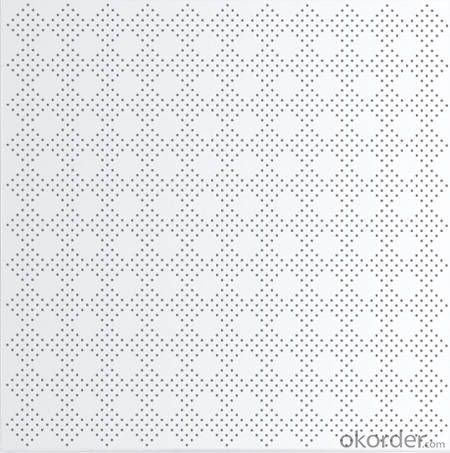

Fiberglass Tile Ceiling Panels - Modern Decorative Home Ceiling Fiberglass

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

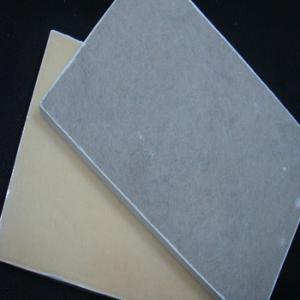

The tile is made by high-density fiberglass with compound decoration wool on the surface and fiberglass wool on the back .The edges are painted. With the characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The panels are udes widely in schools, offices, music studios, lecture theatres,

multi purpose halls, interview rooms, training areas and cinemas. They meet the

requirements of BB93 of Building Regulations for acoustics in school buildings and

are Class O fire rated hence meeting the Fire Regulations as well.

Product Advantages:

Saves headroom space because exceptional noise absorption effectiveness is achieved by low (30mm) material thickness.

Surfaces can be emulsion painted to any colour without significant loss in noise

absorption. Increase savings due to fast and easy installation.Lightweight and therefore are ideal for adhering to ceilings, which do not have a very high load bearing capabilities.

Meets BB93 standards for school acoustics as well as common areas in flats for Building

Regulations.

Reinforced edges for increased durability.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q: If you were a single woman with no man around, how would you fix a hole in the ceiling from water damage? And the roof? On a budget. Is this possible for a small woman to do this job by herself? Can someone give me step by step instructions? Photo of the damage attatched.

- First you need to diagnose the problem of why the water came in to begin with, and resolve it if you can. Without doing that, your ceiling repair is just going to have to be done over again. The other ceiling repair suggestions are good - but they don't speak to the cause of the leak. You don't say what the roof above it looks like, or where you live. Is it flat? Is it sloped? Is it shingled or metal? Can you get access to it. without killing yourself? You do NOT want to be getting out on the roof by yourself; you at least need to have someone holding the ladder, and if it's very steeply pitched, this is really not something you should contemplate doing by yourself. It may simply be due to weather conditions: the snow on the roofs can create ice dams, where the melting water re-freezes and gets shoved underneath the roof shingles. If there is no waterproof underlayment underneath the roof shingles, then the water can seep in under the roof shingles. If this is what's happening, the only thing you can try doing now is to keep your roof as clear as you can. A roof rake (special tool, not an actual rake) can be used to clear the snow away from as far up as can be reached, and it can help prevent ice dams. But frankly, this weather is so bad, that's still not a fail safe. You don't say if you own or rent. If you are renting, this should be up to the landlord to fix, and should not be your problem.

- Q: Fiberglass sound-absorbing ceilings

- Fiberglass sound-absorbing ceiling A-class non-combustible, generally fiberglass material, or a better sound-absorbing material, Jiangsu Sanxian glass fiber sound-absorbing ceiling of the performance can be combined with the indicators, hoping to adopt

- Q: Bathroom waterproof well, why would water leakage?

- No, or waterproof is not done well

- Q: Today, i found my cat sleeping on insulation from the ceiling in our garage. We think this may be why he has been losing his fur on his tummy, armpits, and knees, the skin is pink. Could him sleeping on the insulation be the cause for his fur loss? He also has been constantly licking and cleaning himself. When he cleans himself, he also grabs onto his skin, and pulls it, i guess scratching it because it's itchy.

- Insulation is usually made from fiberglass Have you ever handled insulation with un-gloved hands? If so, can you imagine all these fiberglass shards in his skin? yes, this could be the reason for his fur loss... but that can also settle into his internal system & wreck all kinds of havoc You will have to do something to keep him from getting into the insulation and you need to take the cat to the vet so they can assess internal and external damage done by the insualtion

- Q: Know please elaborate, concrete like, wrapped Nao sand, sticky yarn and the like, thank you.

- Generally do not understand to go to check Encyclopedia (do not waste your points) made of molten glass with very fine fibers, insulation, heat resistance, corrosion resistance, high mechanical strength. Used as insulation materials and fiberglass raw materials.

- Q: Recently the company office to decorate the ceiling, how to choose the material?

- Gypsum board, glass plate, calcium silicate board can be a lot of material, depends on how you choose it

- Q: What are the good fireproof materials now?

- Fire board is currently on the market the most commonly used material, its advantages are fire, moisture, wear, oil, easy to clean, and more varieties of color. Building fire-resistant ceiling ceilings in building exit passages, stairwells and corridors can ensure safe evacuation and protect people from the spread of fire.

- Q: I'm remodeling a bathroom, and I need to know the best insulation for sound/moisture? Also should I use the regular drywall or the green one on the ceiling?

- i have a drop ceiling in my bathroom and use fiberglass plastic coated tiles that give some insulation, are waterproof on the plastic surface and can be (have done this several time) painted after 4/5 years if you so desire or just put new ones in front of the old ones and now the insulation value has doubled. you can keep doing that till they're 3 deep. you can buy them and the tracks that they fit in at home depot. a small bathroom would be less than $100.00 to do. you need to keep in mind when doing those ceilings, always find the MIDDLE of the two connecting walls then measure 12 inches on both sides from the middle. that's where you put the runners. NOT IN THE MIDDLE. now the room is divided equally from the two middles. if you don't then one side will be larger than the other. it may not make sense to you, but believe me it's true. there's not a room in my house that i don't have this system. if you ever get a water leak you just clean up the tile or replace it. use a 2x2 system not a 2 x 4. all the tile comes 2 x 4 (actually a little less) find the exact middle and then cut them in half. not a days work involved. putting up the track is more than 1/2 the job. it must be level all the way around and from side to side some of my ceilings i actually have rolled r-19 insulation on top of those tiles. remember armstrong esprite plastic coated tiles NOT CARDBOARD once the cardboard gets wet it needs to be replaced. i'm not sure but i believe i've had this system in the bathroom for about 20 years now, and other parts of the house for over 30 years, you can paint them or buy new ones and replace them. sometimes that's the wiser thing to do. hope that helps you. greenwall is always better for the bathroom.

- Q: What is the best material for interior decoration

- Now the company said that environmental protection is nothing to point. Such as a wooden side, you go to the test is environmentally friendly, a gypsum board you to detect is environmentally friendly. But if the wooden side and gypsum board, floor furniture are placed in a space to environmental protection? The No one is so good to say, so I tell you the safest way: less use of plastic, less use of the plate (which is compressed with high temperature). The rest I can only tell you the price is relatively high. Water pipe on the line on the line. Blockboard with Garbo's a grade board. The local wire can be. Waterproof is important. Your home if it is not geothermal with ordinary waterproof glue (and cement can use the kind of) can. There is geothermal words so good. OKorder rain rainbow on the line (thick layer of rubber). Wooden side with a small pine can be. What do you want to ask? Jinde's tube ads are good. The time to do the tube is not ever long

- Q: What would be a good cheap insulation for a basement ceiling or wall?

- 1 white styrofoam cost less.

Send your message to us

Fiberglass Tile Ceiling Panels - Modern Decorative Home Ceiling Fiberglass

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords