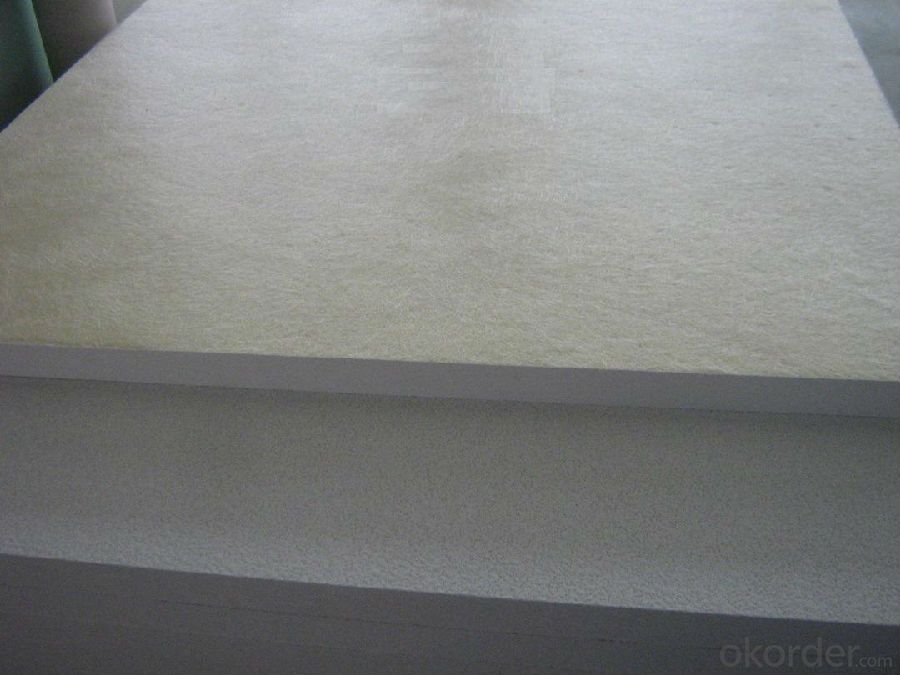

Flexible Fiberglass Acoustic Glass Wool Ceiling Rock Wool Ceiling Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Products Description

Fiberglass Acoustic Ceiling Tiles are great for use in both residential and commercial applications. It is an effective and affordable way to build sound absorbing acoustical ceilings with excellent sound absorption properties. They are effective in eliminating unwanted ceiling boundary reflections and controlling excessive room reverberation. They are widely applied in offices, restaurants, recording studios, theaters, cinemas, schools, garages, conference room, dance halls, etc.

Features

1. Excellent sound insulation.

2. Non-combustible, fire-proof.

3. Light weight and no sagging, wraapping or delaminationg.

4. Green eco-friendly building materials.

Application

It's recommended that this panels be installed to the opposite two walls to cntrol the echo of the surroundings.

The panels are widly used in hotels, meeting rooms, auditoriums, music rooms, libraried, etc, where have special requiest for sound absorption.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 4 weeks after receiving of downpayment

Picture

- Q: Fiberglass sound-absorbing ceilings

- Non-combustible performance: A-level, the national authority of the Cl test, measured (GB9624-1997)

- Q: Why is the state of magnesium dichloride at room temperature?

- Solid, is a crystal.

- Q: This is an old house and has wood and some type of dry cement-type material in between the wood slats. I stepped on the ceiling while doing an insulation job in the attic. The wood is fine but the dryed material cracked and separated from the wood slats in the bathroom. The damages area is around 18 inches by 12 inches, and some cracks in other areas of the ceiling. I do not want to sheetrock the whole bathroom if i can avaoid it (too many projects in this ol house). thanks!

- Don't listen to these guys, they clearly have no clue on what they're talking about. I am a developer at Microsoft so I know a thing or two about computers.

- Q: Specification for acceptance of glass cord sound - absorbing cotton

- The use of high-quality ultra-fine glass fiber high-pressure forming, positive and negative sides covered with glass fiber cloth, the use of professional equipment to play a different surface effect of the product performance of environmental protection, fire, moisture, comfort, antibacterial and decorative economy, anti-pollution, light, shock, environmental protection, European products, raw materials, Production of ultra-fine glass fiber, lead-free, mercury, chromium, asbestos and other harmful, toxic, no smell, the developed countries have been widely used glass fiber products in China, glass fiber product standard design institute included in the standard design Set (03j502-2) Following the gypsum board, silicon calcium board, mineral wool board after a new generation of glass fiber sound-absorbing ceiling. Fireproof European products are all in line with China's highest fire safety standards a (non-flammable level), after a number of European fire tests, have reached the highest level (mo) level. European products using glass fiber and basalt ore as the substrate, the substrate of the non-flammable determines the superior fire resistance, and will not produce toxic gases, no smell. Moisture

- Q: How to choose table tennis floor

- Give you recommend the best floor ~ ~ butterfly king

- Q: How to do a good job of tile exhibition hall design

- Do not think too complicated display design. The focus is on the display of objects. The Look at the scale to set. Are generally based on analog space to locate. A bathroom What about a kitchen. The ceiling is a regional ceiling, usually only the display area. Basic to LOFT style. The According to the style of your tiles to set the inside style, as the layout of a reasonable problem is divided into style partition (European, modern and the like). The Tile type partition (floor tiles, wall tiles). Conditional words to do some platform. Brick parquet, and other commonly used decorative techniques to improve the visual impact, the majority of light-emitting microphone lights. The Key places can use some spotlights or grille lights. University indoor subjects have display design. The Indoor performance techniques. photography. Plane composition. color composition. Three-dimensional composition, and the like. The best landlord or more to go to the Nobel, Smeek such a big shop. The Definitely helpful to you

- Q: How to design a small living room look good.

- You can go and see the exchange space.

- Q: I am doing some minor remodeling on a house. I wanted texture on the walls but didn't want to deal with the mess (and expertise required) of spray texture, so I'm creating a custom texture on the walls by hand using lite joint compound and a 12" taping knife. My question is: what do I do on the ceilings? Can I do the same thing on the walls, or will I kill my back (especially if it needs sanding). I've heard of people wrapping a small piece of plywood in plastic and using it to apply joint compound to the ceiling such that it creates little stalactites that you knock down after they have hardened slightly. That sounds difficult to get uniform across the entire ceiling.What should I do?

- Wow, that's really out of style now, and a big project that is very hard or impossible to change down the road. But hey, you have your own style, thats just my opinion. If you really want to go through with this, DO NOT use joint compound!! It's not designed for this and will crack over time, especially from the lightest bumps that walls sustain, plus houses do move a tiny bit from expansion, contraction, humidity, and settling. This will surely crack the joint compound. I would use a texture thats designed for this, and its more like a plaster, much harder. They sell these special texture mixes at most paint stores and design stores, and also sell different applicators, from sponge applicators that you dab, to grooved spreaders that you swirl. You could always try using regular paint with different texture-like results, that aren't permanent if you change your mind years from now. You can sponge a colored paint to look cool, and they sell special rollers that give a texture pattern.

- Q: What method of repair and what is the material used.

- If you re-do the ceiling may be time-consuming solution: with putty approved twice or so to fill the cracks on the line and then brush on the bottom of a brush on the bottom into a new one.

- Q: which of the following insulating materials that are used in roofs ( foil, fibreglass batts, seaweed) work by trapping a layer of air in them??

- you should make sure to put baffles in against the roof over the eves before you fill it in you do need to get ventilation into the attic or you will cause more damage

Send your message to us

Flexible Fiberglass Acoustic Glass Wool Ceiling Rock Wool Ceiling Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords