Cheap Fiberglass Ceiling Board

- Loading Port:

- SHANGHAI, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 3500 M2 per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

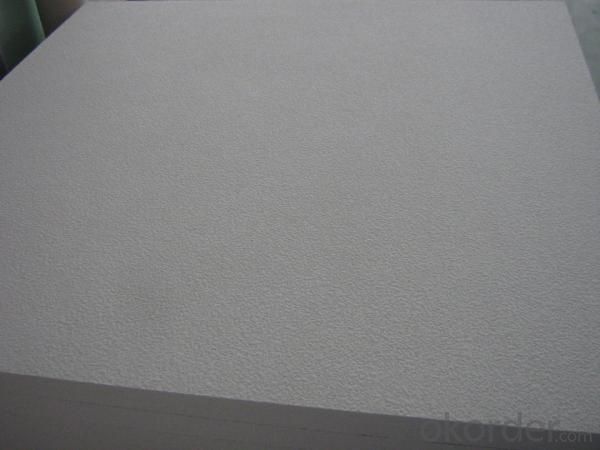

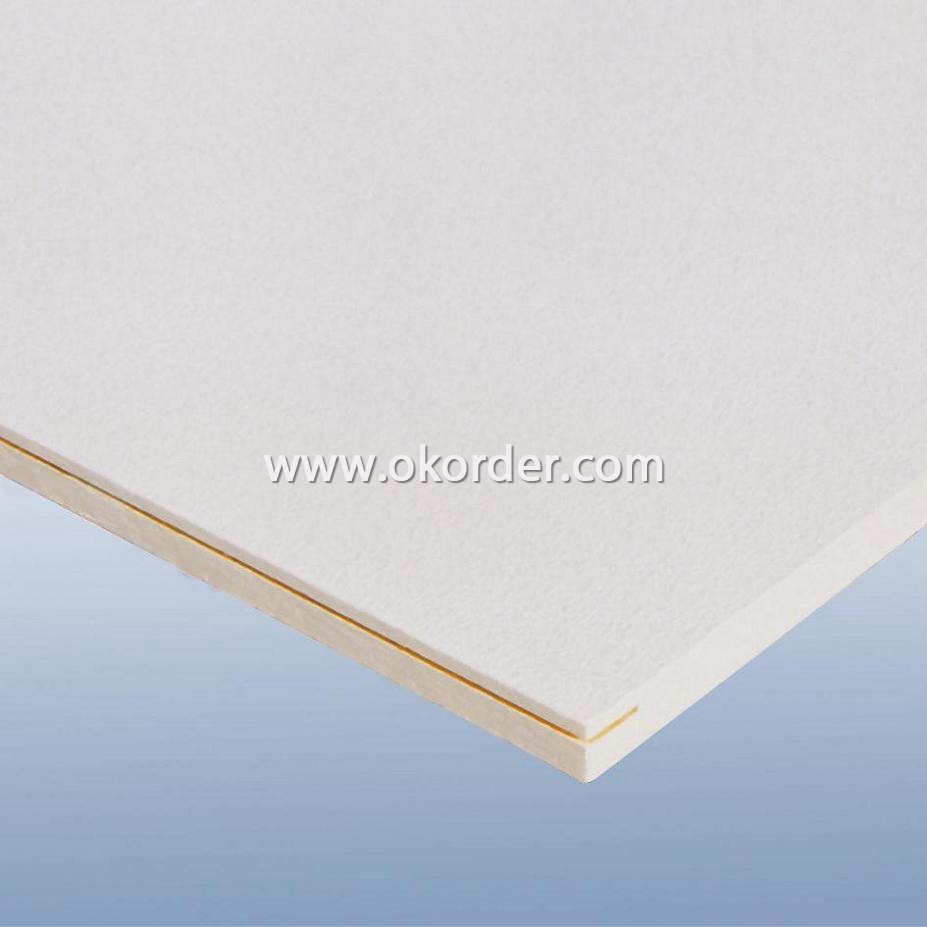

Standard Size: 595mm*595mm, 605mm*605mm…

Standard Thickness: 15, 20, 25, 30, 40, 50mm…

Edge Detail: Square, Tegular, Concealed

Textures: White Painted, Mix Acoustic, White Spray, Black Spray

Technical Data of Fiberglass Ceiling:

Material: High density dry felt resin bonded fiberglass wool

Facing: Special painting laminated with decorative fiberglass tissue

Fire-resistant: Class A, non-combustible according to BS476 Part 6&7 tested overseas

Humidity: Dimensionally stable with RH up to 90% at 40℃

Environmental: Tiles and packing materials are fully recyclable

Main Characteristic of Fiberglass Ceiling:

Excellent sound absorption

No sagging, wrapping or delaminating

Fire-resistant

Moisture resistant

Excellent light reflectance

Cleanable

Environmentally friendly

Application Areas of Fiberglass Ceiling:

Offices, schools, libraries, hotels, cinemas, theaters, etc., where have special request for sound aborption

- Q: I had a stucco like substance on my bathroom ceiling that was peeling and falling off. I scraped it all off and found a layer of pink paint beneath the stucco that also was peeling in many spots. Underneat the paint is plaster that has some spots. I have an exhaust ceiling fan in the bathroom but don't think it works terribly well. I am considering scraping the remaining paint off then filling in uneven spots and corners with spackling compound then painting over the whole thing again but I am concerned that the spackle will not adhere well in the spotted areas. Does anyone have any recommendations?

- The drywall should be replaced. Use a good quality primer / sealer. Mold / Mildew doesn't just go away. It permiates the drywall.

- Q: I kinda left the sink on while i was taking a shower.. so when i got out my bathroom floor had water everywhere (about an inch of water)i mopped up the mess with towels but i forgot to wipe inside the cabinets (and that what caused the water to soak through according to my mom) now i'm being screamed at every. single. day.on the first floor if you look up, the ceiling pretty much dried up but theres 2 creases popping out. kind of like a loong 3-d v shape since the water soaked through and outlined the cabinets shape.and since my mom loves burdening me soo much, now my parents say that they lost 5 grand in our house's value T____Ti don't know if we're supposed to repair it, paint over it (though u can't rlly paint over it), or w/e.. does anyone know what i should do? don't tell me to call a repair man because my parents want to see their 'options' before they call themThanks.. :)

- Peel away the loose and damaged surface. Get a container of 60 min sheetrock mud, fiberglass mesh tape and a trowel. Tape over the seams making sure the tape is IN the ceiling surface, put several coats (thin) on the ceiling, and then try to match the texture if you can. Paint over entire ceiling. This is what a contractor will do.

- Q: How about the whole closet

- With the continuous improvement of modern quality of life, home decoration style is also more humane, professional. The original like a closet, bookcases, lockers, wine coolers and so on every family almost all to use the popular furniture, and now also have a professional breakdown of technology products, and even formed a customization of the overall wall cabinet industry chain. Compared with the traditional woodworking installation method, the owner of their own processing, paint, supervisors, not only labor, time-consuming, bother, more serious part of the toxic ingredients will give the room a long time pollution, unfavorable. ? The whole closet, bookcase not only solve all the above problems, but also to bring a lot of convenience and surprise. Formal brand overall wall cabinet main advantages are the following four aspects: ? First, personalized design ? Technical staff door to measure the size, full respect for the owner arbitrary design ideas, to maximize the owner's personality style. ? Second, make full use of space ? Space utilization, the overall closet can not reserve the hole, directly to the ceiling, the rational use of each inch of space. "L" type, "U" type wall cabinet to make the use of space more reasonable. ? Third, health and environmental protection ? Brand overall wall cabinet by the regular manufacturers in line with international environmental standards of high-quality sheet metal and high-standard hardware accessories production, home installation of finished products, so that the owner meditation to enjoy life, no health worries. ? Fourth, easy disassembly ? Moving or moving in their own family closet position is very convenient, the technical staff free disassembly.

- Q: Who has a building decoration materials Daquan, including indoor and outdoor. It is best to detail the classification, there are pictures the best.

- cleaning tools 1 wash basin: sub-table basin, column basin, hanging basin Wash basin main brands: Kohler, TOTO, American Standard, Wrigley, Slomime, Osman 2 Toilet: roughly divided: washed down, suction macro type Toilet main brands: Kohler, TOTO, American Standard, Wrigley, 3 Bathtub: roughly divided: steel enamel bathtub, cast iron bathtub, acrylic bathtub Usually the bath size: length 1100--1700 range 4 shower room function can be divided into three kinds: bath screen, computer steam room, the overall shower room 5 Sink type: stainless steel sink, artificial crystal stone, granite mixed sink 6 faucet The following are the same as the " Wallpaper type Paper wallpaper 2. clinker wallpaper 3. Textile wallpaper 4. Natural material wallpaper 5. fiberglass wallpaper 6. Metal film wallpaper 7. Liquid wallpaper

- Q: What is the crystal structure of MgCl2

- Chemical Name: Magnesium Chloride [1] (MgCl2) Chemical Description: English name is magnesiumchloride. The chemical formula MgCl2 is composed of 74.54% chlorine and 25.48% magnesium, with a relative molecular mass of 95.21. Was colorless hexagonal crystals. Density 2.316-2.33 g / cm 3. Melting point 714 ° C. The boiling point of 1412 ℃. Usually contains six molecules of crystal water, that is, MgCl2 · 6H2O, easy deliquescence. For the monoclinic crystal, with or salty, there is a certain corrosive. Its density 1.569 g / cm 3, the melting point of 116-118 ° C, while decomposition. Soluble in water, heating and dehydration and hydrogen chloride from magnesium oxide. Use [2]: for the production of metal magnesium, disinfectant, frozen brine, ceramics, and used to fill the fabric, paper and so on. The solution and magnesium oxide mixed, can become hard wear-resistant magnesia cement. Method: from magnesium oxide or lime soil and hydrochloric acid role in the system. Seawater and salt brine are present in the presence of magnesium chloride. The shape of magnesium chloride [3]: generally in flake, block, crystal, particles and powder-based. Content of about 46% of magnesium chloride hexahydrate, 99% of anhydrous magnesium chloride. Magnesium chloride Chemical and physical properties: soluble in water and ethanol. Sensory indicators: white crystals, columnar or needle-like, bitter taste.

- Q: We have an area in our ceiling that had water damage a few years ago and we repaired it ourselves for a quick fix. We never got around to actually getting it professionally repaired, but had never had any issues so it wasn't something we were worried about. About 3 days ago we noticed that there was a hole, about an inch long, I'm the crease of the ceiling where it meets the wall in the same place we had repaired. We don't know if maybe there is a mouse in the wall chewing a hole, if the house finally settled to the point where it cracked our repair job, or if there is another answer. It appears that the holes are only in the drywall tape and not in the drywall itself. Does anyone have any suggestions on what could be going on our who we could call in to inspect this?

- Could be the mold, but simply could be the tape deteriorating. Did you use paper tape? IF you fix it again, use the self stick fiberglass tape before you mud over it.

- Q: What kind of materials do you need to decorate a house?

- wood

- Q: Is it fiberglass, it looks like foam?

- It is thermal insulation. It is usually fiberglass. The foil is for mounting against a wood/combustible ceiling. A non-burning barrier is required. The insulation is so the heat if the lamps doesn't cook the wiring. Most contemporary units are 90 degrees C. Half of the homes have 60 degree C wiring, so they're damaged anyhow.

- Q: New home decoration is the choice of all-inclusive or half-pack good?

- The main material of their own choice, auxiliary materials decoration work package. It is best to find a good decoration work, that would not be too hard.

- Q: What is the relationship between the two? Or who is engaged in the electronics industry, can give me talk about the industry's industrial chain and technical process? Thank you.

- Glass fiber is an excellent inorganic nonmetallic material. English formerly known as: glass fiber or fiberglass. Ingredients are silica, alumina, calcium oxide, boron oxide, magnesium oxide, sodium oxide and the like. It is a glass ball or waste glass as raw material by high temperature melting, drawing, yarn, weaving and other technology. And finally the formation of various types of products, glass fiber monofilament diameter from a few microns to twenty meters a few microns, equivalent to a hair of 1 / 20-1 / 5, each bundle of fiber raw silk has hundreds or even Thousands of single-wire composition, usually as a composite material in the reinforcement materials, electrical insulation materials and insulation materials, circuit boards, widely used in various areas of the national economy.

Send your message to us

Cheap Fiberglass Ceiling Board

- Loading Port:

- SHANGHAI, CHINA

- Payment Terms:

- TT or L/C

- Min Order Qty:

- -

- Supply Capability:

- 3500 M2 per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords