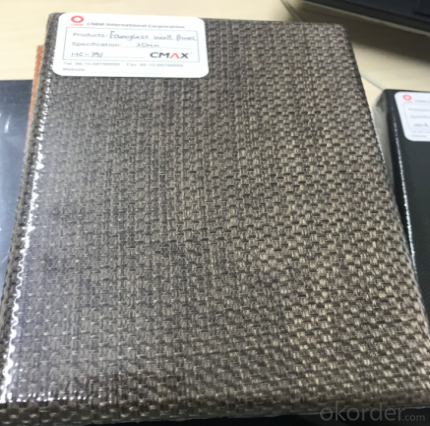

Fiberglass wall panel decoratice fabric acoustic board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass wall panel decoratice fabric acoustic board

Quick Details

Place of Origin:

Jiangsu, China

Brand Name:

CMAX

Ceiling Tile Shape:

Square

Ceiling Tile Type:

Fiberglass Ceilings

Product name:

fiberglass wall panelling for sale

Material:

Glass fiber

Standard size:

600*600 mm, 600*1200 mm, 600*1800 mm

Thickness:

12mm, 15mm, 20mm,25 mm

Advantage:

Heat/sound insulation, sound absorption, environmental protection

Application:

KTV, Hotel, Hanquet hall,Gymnasium, Multi-function

Packing:

15 PCS/CTN or as required

Certification:

ISO9001

MOQ:

100 sqm

Payment:

T/T, Trade assurance, L/C at sight,

Packaging & Delivery

Packaging Details

Packed in cartons for acoustic decorative fiberglass wall panelling for sale

Port

Shanghai, Qingdao,Lianyungang,Ningbo China

Lead Time :

15 days after deposit

Product Description

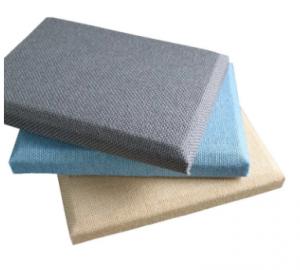

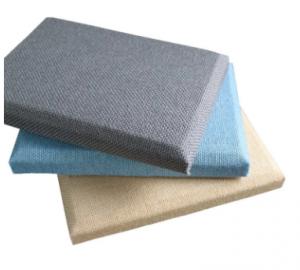

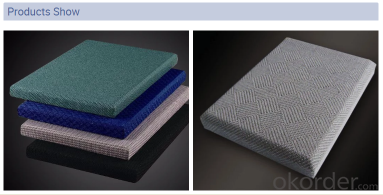

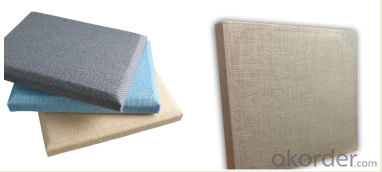

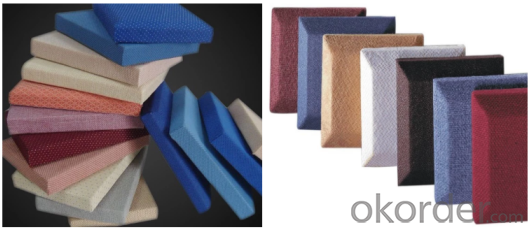

Acoustic Wall Panel Series

Soften space, constant temperature warm effect, the integration of decoration and whole frequency sound absorption. Optional colors and fabrics, meeting the varied acoustic and decorative requirement

Product Name | ISO certificate decorative fabric wrapped fiberglass acoustic wall panel |

Material | Glass fiber |

Frame | flame-retarded resin, wooden, aluminium |

Volume weight | ≥70~100 kg/m³ |

Fire performance | B1 |

Environmental performance | class E1 |

Thickness | 12 mm, 15 mm, 20 mm, 25 mm or 50 mm Customized |

Certification | ISO 9001, ISO 14000 |

Application | KTV, Hotel, Hanquet hall, Gymnasium, Multi-function room, Audio-video room, other acoustic required places |

Product features

Environmental protection

Fire proof

Light weight

Whole frequency sound absorption, especially medium-high frequency

High decorative performance diversified colors and and grains

Anti-microbial

Easy installation

Formaldehyde free, dust free

Customization available upon request

Packing & Delivery

Packing Details : Standard Package

Loading information for regular size:

Size | Thickness | Packing ( PCS /CTN ) | Quantity( 40 HQ ) |

600mm*600mm | 12 | 25 | 13300 PCS /532 CTNS /4788㎡ |

600 mm*1200mm | 12 | 25 | 6650 PCS /266 CTNS /4788㎡ |

600mm*600mm | 15 | 20 | 10640 PCS /532 CTNS /3830.4㎡ |

600 mm*1200mm | 15 | 20 | 5320 PCS /266 CTNS /3830.4㎡ |

600mm*600mm | 20 | 15 | 7980 PCS /532 CTNS /2872.8㎡ |

600 mm*1200mm | 20 | 15 | 3990 PCS /266 CTNS /2872.8㎡ |

600mm*600mm | 25 | 12 | 6384 PCS /532 CTNS /2298.2㎡ |

600 mm*1200mm | 25 | 12 | 3192 PCS /266 CTNS /2298.2㎡ |

- Q: Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound-absorbing, sound insulation, heat insulation, environmental protection, flame retardant and so on.

- Q: Glass fiber mesh quality soft and hard for the wall, which is better?

- The general wall of the grid with a fast money about 1 square meters on the good. Tengda grid cloth 8 hair can also be used. Selling is also good,

- Q: How to do with glass fiber wall anti-crack

- Do not have to be fainted by the glass fiber, although the use of glass fiber, the surface can not see the crack, but in fact still strong, no use, their own fool themselves; recommended landlord with anti-cracking latex paint, such as Mo Wei Latex paint, it can be painted when the wall can make up for the small cracks in the wall, and the film after forming a certain degree of flexibility to prevent the emergence of cracks, this effect is only Mo Weier can do, please landlord reference!

- Q: Is the interior wall made of fiberglass mesh good or wire mesh?

- In any case, when the batch wall putty, is not the use of steel wire mesh, and if it is leveling with cement mortar, then you should use the wire mesh.

- Q: What is the difference between GRC reinforced concrete slabs and lightweight aggregate concrete partitions?

- GRC reinforced cement board: glass fiber reinforced cement board, glass fiber is used as a reinforcing material, plus cement, sand, water, admixture and other materials made of slats, which apply to ordinary or mid-range building grade. Glass fiber reinforced concrete (GRC-Glass Fiber Reinforced Cement) is a new type of composite material.

- Q: What should the overall wardrobe design should have?

- The main features of the overall wardrobe are: standardized modules, tailor-made. The overall wardrobe according to the different styles can be divided into integral, into the wall, support and into the four categories. The overall design of the wardrobe and the pursuit of harmony with the home, in a warm atmosphere of life, bringing a simple and stylish charm, so that you poetic dwelling, artistic life. Therefore, the overall wardrobe style selection and design is essential:

- Q: What is GRC and can I paint it?

- GRC popular understanding of it, refers to the FRP to do the components of profiles. Can be made into any shape, such as sculpture, murals, decorative lines, etc., generally have a good finished product for you to choose. The advantage is high hardness and light weight and the price is not expensive. Is now a large number of decorative materials used. Can be based on your request, do oily or metallic paint, using the basic are spraying process. Another: custom need to open a separate mold costs, so if a small amount of custom, it is more expensive friends.

- Q: Wall material that kind of environmental protection?

- Now environmentally friendly materials are relatively more latex paint and wall cloth are good, but the use of life is limited, weak base of diatom mud to do not only environmental protection can also be used for more than 20 years, is now popular new materials.

- Q: Want to know the glass fiber production process and production process, the more detailed the better, thank you

- The production process of glass fiber generally includes: raw material procurement, according to the formula for mixing, and then transported to the glass furnace for melting, clarification, through the operating channel flow to the drawing board, sizing agent after drawing through the drawing machine to form the original wire (Usually with yarn, weaving, chopping, puffing, twisting, etc.) or for sale (direct yarn)

- Q: Grc light partition board construction steps is what

- 1, the process Material inspection → technology to the end of the net → clean-up → line → fixed U-shaped steel plate card → live installation → detection of vertical, flatness → fixed GRC light partition board → repeat the vertical degree, flatness → support pipe → tied to the joints with → seam mortar → scraping putty → polished smooth → surface coating. The following are the same as the " 2, prepare materials and construction tools Before the construction, need to prepare GRC lightweight partition board materials and doors and windows supporting frame bench material, and to prepare construction tools, such as temporary fixed fixture "U" type fixture, "L" type fixture, to be horizontal angle iron Of the pry bar, woodworking board saw, putty knife, wooden wedge and so on. The following are the same as the " According to the requirements of the drawings, in the wall and the roof pop-up wall and the location of the doors and windows. And the office, corridors, halls and other rooms are ceiling, so the need for height in the partition wall to do hanging columns and hanging beams.

Send your message to us

Fiberglass wall panel decoratice fabric acoustic board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords