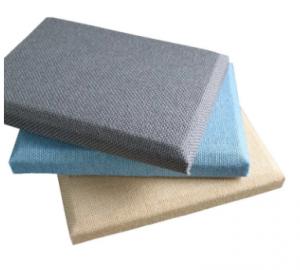

Fabric Wrapped Fiberglass Wall Panel Colorful Acoustic Wall Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

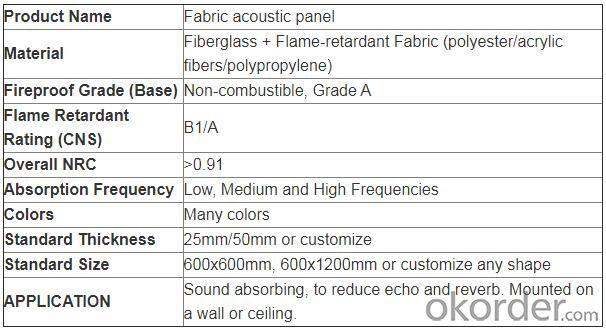

Specification

Description

Fiberglass acoustic panels are made of acoustic fiber and fabric or leather on surface, have excellent soundproof performance in both mid and high frequency. They are decorative and easy to installed. The fabrics on the surface are available in different colors and patterns. Customized is acceptable, you can also provide your own fabrics and designs.

Specification

Application

It is recommended that the Fiberglass Acoustic Wall Panels be installed to the opposite two walls to control the echo of the surroundings. The panels are widely used in Commercial Halls, Classrooms, Offices, Librairies, Shopping Centers, Music Rooms, Auditoriums, etc.where have special request for sound absorption.

Product Features

Environmental protection

Fire proof

Light weight

Whole frequency sound absorption, especially medium-high frequency

High decorative performance diversified colors and and grains

Anti-microbial

Easy installation

Formaldehyde free, dust free

Customization available upon request

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 4 weeks after receiving of downpayment

Picture

- Q: Glass fiber board to do the wall or do ceiling

- Glass fiber board, also known as glass fiberboard, generally used for soft base, outside the package cloth, leather, made of beautiful walls, ceiling decoration. Application is very extensive. With sound-absorbing, sound insulation, heat insulation, environmental protection, flame retardant and so on.

- Q: What is the quality of the light barrier now?

- 1. Thermal insulation performance: insulation than the thickness of 570mm brick wall, can greatly reduce the cooling and heating and other electricity, burning costs, can be described as the best choice for energy conservation. 2. Construction speed: easy to install, more than 8 times faster than the concrete pouring method; wall panels can be sawed, can be nailed, drillable, can be arbitrarily cut, free manufacturing structure. 3. Soundproof and waterproof fire performance: sound insulation up to 45dB, the plate has a self-waterproof function, fire resistance of 2.5 hours or more. Anti-freeze-thaw cycle more than 25 times, moisture-proof performance testing projects have reached the national standard.

- Q: FRP can be used to make walls

- Glass (FRP), also known as GRP, that is, fiber reinforced plastic, generally refers to the use of glass fiber reinforced unsaturated polyester, epoxy resin and phenolic resin matrix. Reinforced plastic with fiberglass or its products as reinforcing material, called fiberglass reinforced plastic, or titled fiberglass. As a result of the use of different varieties of resin, so there are polyester glass fiber reinforced plastic, epoxy glass fiber reinforced plastic, phenolic glass steel said. Light and hard, non-conductive, high mechanical strength, less recycling, corrosion resistance. Can replace the steel manufacturing machine parts and cars, ship shell and so on.

- Q: What is the difference between GRC reinforced concrete slabs and lightweight aggregate concrete partitions?

- GRC reinforced concrete slabs and lightweight aggregate concrete partitions are lightweight wall panels that can be used to make walls. Should be selected materials and processing methods are not the same

- Q: What should the overall wardrobe design should have?

- Wardrobe door panels are glass, sheet and other materials, glass thickness of 5mm, the texture of frosted glass, clear glass, cloth glass and embossed glass and other options.

- Q: What is the difference between an ordinary partition board and a lightweight partition board?

- The partition board refers to the wall prefabricated slabs for the interior wall of the JG / T169-2005 "Building slabs for use with partitions". The partition panels contain glass fiber reinforced cement slabs, glass fiber reinforced Gypsum hollow slab, steel wire (steel mesh) reinforced cement slab, light concrete slats, composite sandwich light bar and so on. The full name is the construction of the wall with a light strip, as the usual industrial construction, residential construction, public construction of non-load-bearing wall of the main information.

- Q: Wall material that kind of environmental protection?

- Glass fiber wall cloth, that is, wall fabric, the function is relatively strong, it is made of glass fiber, not only environmentally friendly, and fire anti-cracking moisture, scrub resistance, good care, life of more than 10 years. Whether the project or home improvement is a good choice.

- Q: The difference between GRC lightweight partition board and ceramic plate

- A plate made of ceramsite concrete, usually a non - load - bearing wallboard.

- Q: Inorganic fiberglass contrast color steel composite board which is good? Requirements insulation good! preservative! Thank you

- Fiberglass is a glass fiber reinforced plastic commonly known as it is a glass fiber reinforced material, synthetic resin as the base material of the composite products. FRP has a good anti-corrosion properties. Especially the water and dilute the concentration of acid Liquid, and can show its superiority, and FRP lightweight high strength specific gravity of 1.7-1.8 is a quarter of steel.For the insulation: you can use polyurethane foam. With light weight. High strength. Low thermal conductivity. Non-absorbent and other characteristics. Has been widely used in travel. Building. Cold storage. Refrigerator. Petrochemical. Indoor air conditioning.

- Q: Grc light partition board construction steps is what

- 1, the process Material inspection → technology to the end of the net → clean-up → line → fixed U-shaped steel plate card → live installation → detection of vertical, flatness → fixed GRC light partition board → repeat the vertical degree, flatness → support pipe → tied to the joints with → seam mortar → scraping putty → polished smooth → surface coating. The following are the same as the " 2, prepare materials and construction tools Before the construction, need to prepare GRC lightweight partition board materials and doors and windows supporting frame bench material, and to prepare construction tools, such as temporary fixed fixture "U" type fixture, "L" type fixture, to be horizontal angle iron Of the pry bar, woodworking board saw, putty knife, wooden wedge and so on. The following are the same as the " According to the requirements of the drawings, in the wall and the roof pop-up wall and the location of the doors and windows. And the office, corridors, halls and other rooms are ceiling, so the need for height in the partition wall to do hanging columns and hanging beams.

Send your message to us

Fabric Wrapped Fiberglass Wall Panel Colorful Acoustic Wall Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords