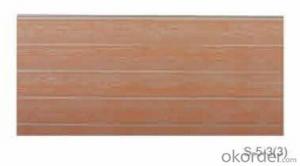

Fiber Cement board for villas,high building-014

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The fiber cement board includes two series: solid fiber cement board(S series) and hollow fiber cement board (K series)

Fiber cement board is one new type wall board which is both functional and decorative, with idea of high- tech and innovation, the products combine the traditional and modern science and technology, which provide a brand new green wall decoration material to the exterior wall field.

K series

3000 * 300* 15mm

3000* 450* 18mm

3000*600* 26mm

K series—Streak board

3000*300*18mm

3000*300*22mm

3000*600*26mm

The colors are based on customer’s choice.

Fiber cement board: exterior wall decoration system

This system is widely used in public building and high end residential and other kinds of civil construction of exterior wall decoration. In existing buildings exterior wall decoration, the fiber cement board can be directly mounted to the exterior wall by keel, and not need to remove the original façade decoration materials. This system could give the construction quick speed, low transformation cost and good decorative effect.

Fiber cement board: exterior wall heat preservation system.

This system can meet different design requirements for energy- saving. The system has excellent heat preservation and heat insulation performance, meanwhile, the mass production and quality control of the products overcomes the crack problem occurred in other external insulation system. The system are mainly used in energy saving renovation to existing building or the external wall thermal insulation of new construction.

Fiber cement board composite wall system has good heat preservation, heat insulation and sound insulation performance, which make the system become an high and energy saving wall retaining system. The system could be applicable to the façade of steel or wood frame villa, and non bearing exterior wall for structural frame work or other frame structure.

- Q: Installing tile in my laundry room. put down the cement board with a mortar/thin set base under it, then nailed it down according to manufacturer's instructions. The mortar/thin set totally dried then I had to do a few loads of laundry before I was able to put any tile down. Unfortunately one of the hoses hooked up to the washer leaked and soaked the cement board and I'm sure also the sub-floor. Do I need to rip out the cement board and re install before I install the tile? obviously I would need to ensure the floor is fully dry before I install the tile. Thanks

- I do not think you need to rip it out. Just let it dry for a week or so before you install the tile.

- Q: Asbestos cement board product features

- Fire insulation: non-combustible A-level, the fire will not burn when the plate does not produce toxic smoke; low conductivity, is the ideal insulation material.

- Q: I have Hardibacker cement board down for ten years. Just removed the ceramic tile and mortar from it for a new tile job. Do I need to retape the joints or should they be stable at this point. The cement board was screwed into postion.

- its a waste of time to tape the joints. once the substrate is combed with cement its bonded together taped or not.

- Q: i am having alotta trouble on the cement like i cant get both feet back on the board.any tips?

- probly because in grass your more confedent because you did it lots of times and mabye because the grass was slippery 20% of the time or so.

- Q: I have a bare concrete/cement floor. After I installed Travertine on one section, it is almost 1/2 inch above the floor. Now, I want to continue to install the other section of the floor with laminate wood, but the floor is too low compared to the travertine floor. The question are: Can I put down a particle board over the concrete/cement floor, then a foam pad (moisture barrier), then laminate wood?Will the particle board absorb water then swell up?Or do I need to put down the moisture barrier foam first, then particle, then laminate wood?If I am not using the particle board, the laminate wood floor will be about 1/8 lower than the travertine floor. is it ok?

- 1/8 isn't very much. You'll need t-moulding (transition moulding) between the two materials anyway. Rather than PB or ply, why not cleant he concrete, cpply primer, and pour self leveler on it? You'll make up your 1/8 in no time, without worrying about moisture affecting the substrate. Even plywood will warp and delaminate over time if exposed to moisture. You could get marine grade plywood (mdo or something, i've only had to get it once) but it'll be hard to come by the thickness you need in any substrate. Or just leave it alone and get a t-moulding that will make a transition over the 1/8 difference. They make plenty of different profiles.

- Q: How to choose their own materials made of steel structure compartment?

- 1) Pure steel loft (2) Steel loft (3) Fiber cement board loft (4) Steel wood attic (5) Plant workshop second floor loft craft materials and methods have many options: A wooden structure loft; Cast steel structure loft; Iron plate steel loft; Steel loft and so on.

- Q: This is when you are installing tiles over existing cement patio. Idk if it's a board, it seemed bendable. I saw it on HGtv And I can't remember what it's called

- It's called Hardyboard. Used it to tile an entryway; good stuff. If you are going over existing cement, you don't need it. Fill any cracks you might have, sweep it good, and then just trowel on the mastic and set your tiles.

- Q: What are the standards for residential steel structures?

- Steel structure residential system is composed of the envelope structure and steel support structure of the common residential system, is the province of energy-saving new residential system. It is the steel structure of the house to abandon the solid clay brick, the effective use of land resources. Steel residential buildings have advantages in terms of functional, design, construction and integrated economy compared to traditional homes

- Q: almost finished with tiling on cement board wall. ran into problem with corner applying bull nose piece.?

- Let me guess. You got to cut it. Guessing is all we can do here when you do not have a complete thought written down.

- Q: i can ollie on a rug ok but then on the cement my board moves and the back wheels dont get up i know i am doing the ollie right but when i try it on the cement the board moves and the back wheels dont go up i really need help because most of my friends skate and they are really good and i would like to start skating but i dont know if i am good please give me some tips about ollieing on the cement thanks!

- Your pushing your board back with your feet. Try not to do this and practice. The only way to be good in skateboarding is practicing everything hard.

Send your message to us

Fiber Cement board for villas,high building-014

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords