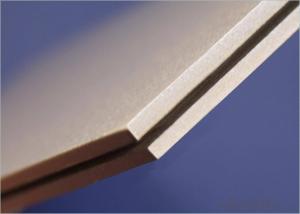

Fiber Cement Board 1220*2440mm Fiber Cement Board 1220*2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The tile is made by high-density fiberglass with compound decoration wool

on the surface and fiberglass wool on the back .The edges are painted. With the

characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The titles are manufactured from high density dry felf resin bonded fiberglass wool, with fine texture painted glass tissue facer,plain tissue backer and sealed and painted edges.square edge titles will be paralled to suspension system after installation.

Product Advantages:

1)Incombustibility/Non-flammability: Consmos Calcium silicate board is non-flammable and conforms to the national grade A standard (GB8624 Grade A) with excellent fire resistance property. In case of fire, the board will not burn and not give off toxic smoke.

(2)Thermal/heat insulation: Owing to low heat conductivity, the product has good performances on keeping warm and heat insulation.

(3)Water-proofing and moistureproof: The product is allowed to long-term exposure to moist environment but still very stable. The board still keeps intact after being soaked in water for one month, the phenomenon of swelling and out of shape will not happen. It has good adjusting mechanics like woods. Even it is used on wash house.

(4)Endurance/durability: Consmos Calcium silicate board provides good insulation against bugs, fungus and corrosion. It can last for a long time and will not corrode.

(5)Noise-proofing: Consmos Calcium silicate board provides good insulation against noise.

(6)High-Strength and Light weight: The board is light weight, in this case, it can decrease weight of building greatly. At the same time, the material is high-stength and not easy to be damaged.

(7)Easiness to installation: The construction process does not require complicated tools but just the ones used in regular wood construction. Our board can be fixed on light steel frame with self-attachable screws or a glue gun to nail the bolts into the wooden frame.

(8)Environmental protection: Consmos Calcium silicate board is 100% free of asbestos fiber and will not cause any harm to human body or the environment.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q: Can cement tiles be directly on the cement board? What material is good?

- Cement board is a cement as the main raw material processing and production of a building plate, is a between the gypsum board and stone, free cutting, drilling, carving of the building products, with its superior to gypsum board, wood fire , Waterproof, anti-corrosion, pest control, sound insulation and far lower than the price of stone and become the construction industry widely used in building materials. The cement board is prefabricated and also cast.

- Q: Hello, my husband and myself are remodeling our bathroom....here's the question... we removed hideous vinyle tiles and underneath is the cement floor with thin layer of black adhesive from the tiles....the floor is pretty sound except for a small crack in cement by the entry door.... should we fix the crack and tile over the cement? or thin set 1/4''cement fiber board to the floor and tile over that? and if we do use the fiber board is the thin set enough to hold it down? we can't really screw/nail it cuz subfloor is cement. Any help is appreciated! Thanks!

- I am assuming you are going with ceramic tile. If that is the case then you do not need fiberboard. Just tile right to the concrete floor. As for the crack either fill it in or use a product called RedGaurd. RedGaurd is a rubberized product that when applied over the crack will expand and contract and thus keep the crack covered. You can apply RedGaurd then put mortar right over it.

- Q: okay so im making a notebook collage n i was wondering if i can use rubber cement...oh and does it dry clear because i added some now and it's kinda dark colored and i don't want people to see the stains.. i dont have an eraser or anything like that!

- I used it many times to temporarily glue photography artwork to the matting board. The good thing about it -- it is removable when dry. Just scrub it lightly with a paper towel or even with your fingers. I buy my rubber cement in art supply stores, it is not dark colored at all and they also sell a convenient big rubber eraser for it. Beware: it is not to create a permanent bond; the photos will fall off in time.

- Q: Seeking wire mesh clip on both sides of the foam cement mortar to do the wall technology.

- With light steel keel, cement board to do both economical and light weight. In the middle with rock wool to insulation sound insulation

- Q: Is it a decoration material? What's the difference?

- Wood wire cement board VIVA wood cement board and Smile wood cement board, a specification is 1220x2440, one is 1200x2400, in terms of material are the same, but the surface treatment is not the same, a strong degree of wear resistance, a resistance Grinding degree slightly worse, the thickness of 8.10.12.16.20.24, the United States rock cement board FOREX Meiyan cement board and diamond american cement board, a specification is 1220x2440, one is 1200x2400, the thickness of 6.8.10, the current China is generally 6 and 8, 10 very few.

- Q: What can I put on the two walls that have the cement backer board? Is there only certain things that I can put on them. They are about 3 ft. away from the stove. What is the code for this. I am at a loss, but I need to do something about this. Anyone know about wood stove codes. Thanks...

- Codes are local, usually by county. Requirements can usually be gotten for free from your county planning office. You'll most likely be able to use a clay-based tile. You local codes will decide if you have to use a high-heat mortar or not, it's always best to check before starting work. Good luck!

- Q: We are redoing a small bathroom and I want to redo the old tile and also add some additional tile around some of the other walls. We are planning to use cement board around the tub, but do I need to rip out existing wallboard around the vanity and other walls where I want to add new tiles and replace it with cement backer board? Or should I just add the cement board on top of the existing wallboard in the places I want to add new tile ( I was thinking about maybe tiling halfway up some of the other walls). Thanks!

- Cement board is only needed around a tub or shower, Adhere the tile with a modified thinset adhesive. Use mastic (glue made for tile) on the existing drywall rather than thinset on the rest of the room.

- Q: where can i buy national gypsum perma base cement board?

- Haven't thought about that

- Q: How to install the outer wall plywood

- Before installation, please determine the number of hanging plates and accessories according to the actual situation of the house. In addition, the use of some suitable tools and equipment during the installation will help to improve the installation speed and effect. Commonly used tools are: electric saw (desktop or portable), hand hammer, fine tooth straight knife saws, rectangular ruler, level ruler, tape, ink line, protective glasses, tool knives, iron scissors; Hole clamp.

- Q: i live in a country where houses are made with bricks..but i made my house just like in USA , but there is one only problem i need cement board to finish the bathroom , since we don't have cement board here for sale , and i can't afford import from USA , i was wondering that i can make it , i'm sure that i can make it , but i just need to know how to prepare de cement i would be appreciated if anyone help me thanks

- Surely you must be able to purchase something equivalent? If Wonderboard is not available, how about Hardibacker? Or Cembonit?

Send your message to us

Fiber Cement Board 1220*2440mm Fiber Cement Board 1220*2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords