Fiber Cement Board 1200*2400mm Fiber Cement Board 1200*2400mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

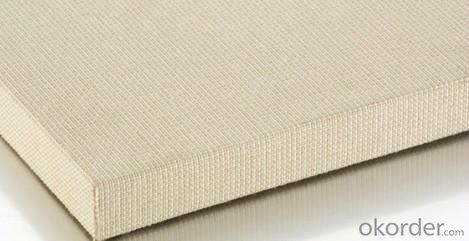

The tile is made by high-density fiberglass with compound decoration wool

on the surface and fiberglass wool on the back .The edges are painted. With the

characteristics of square in edges and angle,it will be parallel to suspension system after installation.

Product Applications:

The titles are manufactured from high density dry felf resin bonded fiberglass wool, with fine texture painted glass tissue facer,plain tissue backer and sealed and painted edges.square edge titles will be paralled to suspension system after installation.

Product Advantages:

1)Incombustibility/Non-flammability: Consmos Calcium silicate board is non-flammable and conforms to the national grade A standard (GB8624 Grade A) with excellent fire resistance property. In case of fire, the board will not burn and not give off toxic smoke.

(2)Thermal/heat insulation: Owing to low heat conductivity, the product has good performances on keeping warm and heat insulation.

(3)Water-proofing and moistureproof: The product is allowed to long-term exposure to moist environment but still very stable. The board still keeps intact after being soaked in water for one month, the phenomenon of swelling and out of shape will not happen. It has good adjusting mechanics like woods. Even it is used on wash house.

(4)Endurance/durability: Consmos Calcium silicate board provides good insulation against bugs, fungus and corrosion. It can last for a long time and will not corrode.

(5)Noise-proofing: Consmos Calcium silicate board provides good insulation against noise.

(6)High-Strength and Light weight: The board is light weight, in this case, it can decrease weight of building greatly. At the same time, the material is high-stength and not easy to be damaged.

(7)Easiness to installation: The construction process does not require complicated tools but just the ones used in regular wood construction. Our board can be fixed on light steel frame with self-attachable screws or a glue gun to nail the bolts into the wooden frame.

(8)Environmental protection: Consmos Calcium silicate board is 100% free of asbestos fiber and will not cause any harm to human body or the environment.

Main Product Features:

Material: Torrefaction Compounded high density fiberglass wool

Face: Special painting laminated with decorative fiberglass tissue

Color: white, black and others to order

Fire-resistant: class A, non combustible

NRC: 0.9-1.0, excellent sound absorption

Thermal-resistant: >0.4 (m2k/w)

Humidity: Dimensionally stable with RH up to 95% at 40c, no sagging, wrapping, or delaminating

Moisture rete:<1% (JC/T670-2005)

Enviromental impact: Tiles and packing are fully recyclable

Product Specifications:

FAQ:

1)Q:Are you a factory or trading company?

A: We are a factory.

2)Q: I am interested in the products but I do not have experience

A: Tell us your budget and target market and we will give you professional advice of exact kinds and quantity.

3)Q: How can I get some samples?

A: We are honored to offer you samples.

4)Q:How does your factory do regarding quality control?

A: Quality is priority, we always attach great importance to quality controlling from every worker to

the very end.

Images:

- Q: i am going to be installing tile in my bathroom as a tub surround.i am wondering what backer board is needed. if i am using a membrane such as kerdi, is drywall a good enough backer or do i need cement board. if i need cement board, do i need the membrane? what products do you suggest for best installation. i will also be doing a walk in shower. are there any differences to be aware of compared to the tub surround shower style.

- I am assuming you are going with ceramic tile. If that is the case then you do not need fiberboard. Just tile right to the concrete floor. As for the crack either fill it in or use a product called RedGaurd. RedGaurd is a rubberized product that when applied over the crack will expand and contract and thus keep the crack covered. You can apply RedGaurd then put mortar right over it.

- Q: Cement board to do the bathroom top off the skin, how to deal with

- A long time and out, paint can be directly sprayed up, putty powder

- Q: I'm installing a new bathtub, can I attach the tub to the cement board?

- Yes, they did this on Blue Peter last year from velcro, a washing-up liquid bottle, and some sticky-backed plastic - remember when you're using the scissors to ask an adult to help!

- Q: thinking of using Wedi Board to renovate a shower, this product is great for tile but saw a show room shower that used scratch coat cement, how hard is this to do compared to tiling?

- If you mean instead of tile, remember that unless you plan to paint it - concrete or cement is not waterproof. Think of a concrete pool - it requires periodic painting (maintenance). There are a lot of thin solid surface products out there if you do not want to look of tile. Tiling is not that hard as long as you prepare properly and take your time. There are alot of site with tiling guidelines out there - the important thing is to install/prepare the surface properly and seal the grout when you are done.

- Q: I plan on tiling a bathroom in a basement. I was wondering could I just glue the backer board on the painted cinder block walls. I don't want to use screws or nails.

- usually 1x material is secured to the blocks and then the cement boards or drywall is attached to the strips

- Q: I am installing a new tub and enclosure. I have exposed everything down to the studs and plumbing. I have heard that when installing backer board in a shower the best material to use nowadays is cement backer board (like Durock) since they are more resistant to mold than green board. Anyways, what is the correct process for installing cement backer board in a shower? Do I just screw the boards right into the studs, or do I have to first put down another thin barrier sheet (like some waterproof material), then the cement backer board, then another waterproof sealant, then I can install the enclosure? I just want to do this right the first time and not leave any steps out of the process. I would hate to develop another moisture leak and then find out that my barrier did not hold up well. Thanks and take care, I appreciate any help.

- You did not specify if you were using a tub shower fiberglass kit. Some kits require that the tub and surround are attached directly to the studs. Check with the manufacturer for installation details. If you are using ceramic tiles around tub than green board or durock is fine.

- Q: Aluminum-plastic board Aite board lighting board are used in what place

- Etter board is generally used for ceiling and partition, aluminum-plastic panels used to do facade decoration, signs, etc., the use of lighting is not very wide.

- Q: Bathroom renovation. New shower installation. Question is when installing the cement boards along the shower w?

- I agree.. Whats the question?.. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: What are the risks if we do not install cement board first, if any?

- Not putting an additional subflooring is almost a guaranteed failure. ATC and TCA are tile code guide lines that state that a minimum of 1 1/4 subflooring is needed to do tile. There are other circumstances ( like deflection) that come into play , but properly prepped subflooring is the best bet against failure. It doesnt need to be a cement board ( and there is a proper installation method) .There are other ways , depending or your exact situation that can be used to properly do tile. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: i live in a country where houses are made with bricks..but i made my house just like in USA , but there is one only problem i need cement board to finish the bathroom , since we don't have cement board here for sale , and i can't afford import from USA , i was wondering that i can make it , i'm sure that i can make it , but i just need to know how to prepare de cement i would be appreciated if anyone help me thanks

- Back in the old days(I'm an old man) they used lathe and plaster. They also used lathe and cement. Lathe and plaster with a cement coating.

Send your message to us

Fiber Cement Board 1200*2400mm Fiber Cement Board 1200*2400mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords