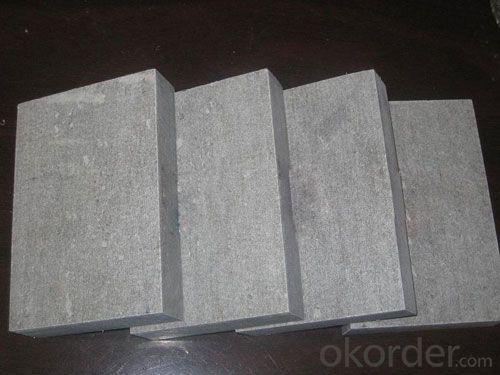

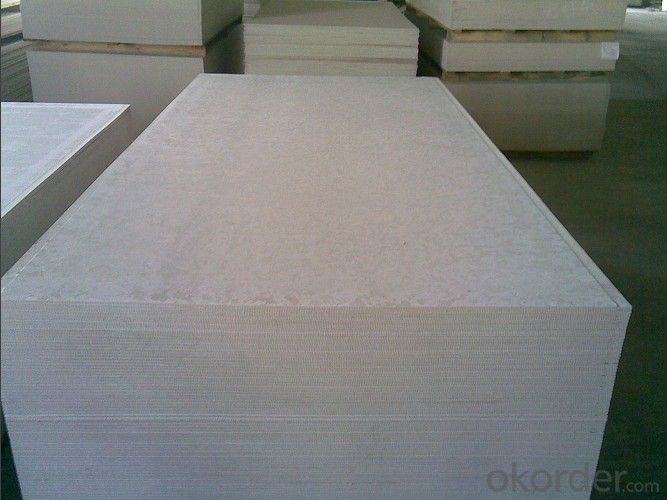

Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

(Raw materials: pure quartz powder, quick lime, calcium silicate, plant fiber and many fined mineral stuffing including dispersant and additive) into a wet sheet and then through high temperature and high pressure autoclave for more than 10 hours by advanced technology. That it will compose a special calcium silicate board. There is no asbestos, brucite and meerschaum in the raw materials and the formulations at all.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1. 100% asbestos free, environmentally friendly

2. Non-combustible Class A, does not release poisonous gas.When in contact with fire, smoke index is zero.

3. Light weight and high intensity, helps reduce the cost of building Based on stone crystal, best stability and not affected from temperature.

4. Good performance in heat preservation and insulation mildew proof and moth proof.

5. 100% asbestos free

6.Low thermal conductivity

7.Good compression strength

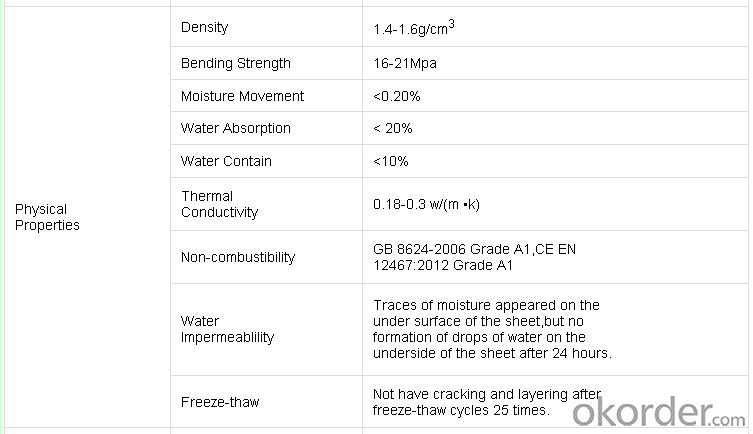

Main Product Features:

100% asbestos-free

Product composition: Portland cement, highly pure quartz sand, cellulose fiber

Density: 1.1-1.4 g/cm3

Water absorption: ≤30%

Moisture interference degree: 0.27mm

Moisture content: ≤10%

Swelling: ≤0.25%

Dry shrinkage rate: 0.5%

Impact resistance: ≥2.0 KJ/m2

Flexural resistance: ≥12 KJ/m2

Thermal conductivity: ≤0.2 W(M.K)

Screw-pull force: ≥75 N/mm

Frost resistance: After 25 freeze-thaw cycles without rupture and layer phenomena.

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

•Q: How about our quality?

A: We provide international quality.

Images:

- Q: Glass fiber reinforced cement (GRC) board is what

- GRC is glass fiber reinforced cement products. He is composed of anti-alkali glass fiber and low alkalinity cement composed of a new type of hydraulic composite material, its main features are high strength, crack resistance, fire resistance, good toughness, not afraid of cold, easy to shape, can be made into thin, , The shape of a variety of complex building components and products, in the civil construction of agriculture, animal husbandry and fishery and environmental art and other fields have a wide range of uses. GRC Finished material is made of this composite material such as: GRC European-style components, high-strength GRC curtain wall panels, etc.

- Q: Light steel keel cement board is what

- Light steel keel is a high-quality continuous hot-dip galvanized strip as a raw material, the cold bending process from the building with metal skeleton. It is used for decoration of non-load-bearing walls and roofs of concrete such as gypsum board, decorative gypsum board and other lightweight panels. Suitable for a variety of building roof decoration, the building inside and outside the wall and scaffolding ceiling of the basic material. According to the use of hanging keel and cut keel, according to cross-section of the form of V-type, C-type, T-type, L-keel.

- Q: Outdoor doors of the aluminum-plastic plate can be directly in the waterproof cement board paste it?

- can. But when the aluminum-plastic plate, then a long time will be knocked up. After all, the wind and sun is just a matter of glue

- Q: I have a walk in closet with plywood pieces for a floor. Don't I need cement board installed before putting in wood flooring? Thanks for your help!!

- You dont need cement board . You would just install it over the plywood subfloor. Personally I would go down to Home Depot or similar store and look at their floring and talk to a salespersomn there. If you have not done this before you need to find professional help.

- Q: The roof of the cement board everywhere cracked, how to do

- At present, the better choice is the polymer waterproofing membrane: waterproof concrete and waterproof mortar two, this waterproof method is simple, easy construction, ordinary masons according to the general plaster construction method can achieve good quality requirements, and low cost , The same waterproof method under the premise of technical level, the overall cost is much lower than the flexible waterproof material for other waterproof materials 1 / 2-1 / 3, the most important thing is safe non-toxic environmental protection, but if the construction process is not good, Cement mortar is likely to crack, repair will be more trouble.

- Q: Can the Etch board be used for the bathroom?

- It is best not to use, Ed board in a damp place for a long time easy to mold, interface cracking, yellowing. I suggest you use a single brick wall, strong and durable. If you feel more blunt, you can use glass brick wall. Fixed waterproof material for the bathroom is a wise choice, if you think your bathroom waterproof very good, or no steam and the like, then you just used. (Oh you want the wall and then thinner, you can use moisture-proof wood or antiseptic wood to do, but the general use of the plate)

- Q: Do you know that light through the cement? What is the material and how to do it?

- Litracon is a widely used new building material with light transmission properties. It is a compound of fiber and fine grinding cement that can be used to produce construction and installation of prefabricated blocks and cement boards. As the fiber size is small, so as a new ingredient mixed with the cement together to form a collection. Therefore, the final not only in the cement is mixed with two components of glass fiber only, but in the internal structure and the surface can achieve a balanced effect of new building materials. From thousands of optical fibers in parallel between the two sides of the cement block to form a policy. The proportion of fibers is very low (4%) throughout the cement block. In addition, because the fiber size is very small, so become a cement structure of a collection of components, cement block surface or uniform cement. In theory, the light-permeable cement block can be built with a few meters of thickness of the wall, because the fiber in principle, within 20 meters will not lose any light information. The fiber does not affect the high capacity of the cement, so in these cement blocks can build any load of the building structure. The light-permeable cement block can be produced in a different size, and a heat-insulating layer can be added thereto.

- Q: Gypsum board and cement board decoration room difference

- Cement board is used to heat, do a class of partitions, the top can not hang the finish paint. Gypsum board is used to decorate the wall surface, used to flatten the wall. They are of two nature. The characteristics of the two plates are not exactly the same, depending on which part of the use. If it is for the ceiling, then use gypsum board; if it is as a wall, and to the tile on the wall, then you should use cement board.

- Q: A list of US suppliers is here w/ some discussion.

- Haven't experienced it but from what I read in your link, it gets hung/nailed like drywall and underlayment. If you're not familiar with how to hang drywall, the first link is a very informative step by step video. Second link, though not a video is how to install cement board/fiber underlayment. Hope this will be of help to you - good luck!

- Q: I want to install ceramic tile in my kitchen. My subfloor consists of 2x8 on 16 centers with 1/2 5 ply plywood. Will it be OK to lay 1/2 cement board directly on this or do I need to some how increase the strength of the subfloor? Any recommendations.

- you could do that and MAYBE not have a problem. but if it was me, the 1/2 would come out and 3/4 would replace it. i have done a few jobs for people that dont want to replace the 1/2 and didn't have any problems with the tile or grout lines cracking. its just up to you really. if there is ANY give at all on you floor right now, id replace the 1/2.

Send your message to us

Calcium Silicate Board High Quality Partition Wall

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords