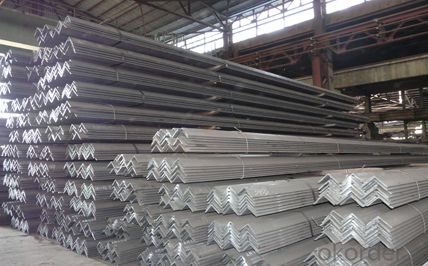

Equal Angle Steel, American Standard Steel Angles, Carbon Steel Angle Iron

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Equal Angle Steel, American Standard Steel Angles, Carbon Steel Angle Iron at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Equal Angle Steel, American Standard Steel Angles, Carbon Steel Angle Iron are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Equal Angle Steel, American Standard Steel Angles, Carbon Steel Angle Iron are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1: Galvanized angle

2. Size: 20 x 20 to 200 x 200mm

3. Thickness: 3 to 24mm

4. Length: 5.8/6m,11.8/12m for bulk vessel

Key Specifications/Special Features:

Materials: ASTM A36, A572; Q235, Q345; SS400, Gr.50, EN 10056, S275, S355

Size: 20 x 20 to 200 x 200mm (Special size will be available as per request)

Thickness: 3 to 24mm (special size available as per request)

Length: 5.8/6m,11.8/12m for bulk vessel

Type: Equal

Primary Competitive Advantages:

· Form A

· Guarantee/Warranty

· International Approvals

· Product Features

· Prompt Delivery

· Quality Approvals ISO9001:2000

Application: construction Structural steel

Packaging Details: standard exporting package in bundle

Length*Length*THK(mm) | Weight(kg/m) | Length*length*THK(mm) | Weight(kg/m) |

25*25*3 | 1.124 | 70*70*6 | 6.406 |

25*25*4 | 1.459 | 70*70*7 | 7.398 |

30*30*3 | 1.373 | 70*70*8 | 8.373 |

30*30*4 | 1.786 | 75*75*5 | 5.818 |

40*40*3 | 1.852 | 75*75*6 | 6.905 |

40*40*4 | 2.422 | 75*75*7 | 7.976 |

40*40*5 | 2.976 | 75*75*8 | 9.030 |

45*45*3 | 2.088 | 75*75*10 | 11.089 |

45*45*4 | 2.736 | 80*80*6 | 7.376 |

45*45*5 | 3.369 | 80*80*7 | 8.525 |

50*50*3 | 2.332 | 80*80*8 | 9.658 |

50*50*4 | 3.059 | 80*80*10 | 11.874 |

50*50*5 | 3.770 | 90*90*6 | 8.35 |

50*50*6 | 4.465 | 90*90*7 | 9.656 |

63*63*5 | 4.822 | 90*90*8 | 10.946 |

63*63*6 | 5.721 | 90*90*10 | 13.476 |

63*63*8 | 7.469 | 100*100*6 | 9.366 |

70*70*5 | 5.397 | 100*100*7 | 10.83 |

70*70*6 | 6.406 | 100*100*8 | 12.276 |

Length*Length*THK(mm) | Weight(kg/m) | Length*length*THK(mm) | Weight(kg/m) |

100*100*10 | 15.12 | 160*160*10 | 24.729 |

100*100*12 | 17.898 | 160*160*12 | 29.391 |

110*110*7 | 11.928 | 160*160*14 | 33.987 |

110*110*8 | 13.532 | 160*160*16 | 38.518 |

110*110*10 | 16.69 | 180*180*12 | 33.159 |

110*110*12 | 19.782 | 180*180*14 | 38.383 |

125*125*8 | 15.504 | 180*180*16 | 43.542 |

125*125*10 | 19.133 | 180*180*18 | 48.634 |

125*125*12 | 22.696 | 200*200*14 | 42.894 |

125*125*14 | 26.193 | 200*200*16 | 48.68 |

140*140*10 | 21.488 | 200*200*18 | 54.401 |

140*140*12 | 25.522 | 200*200*20 | 60.056 |

140*140*14 | 29.49 | 200*200*24 | 71.168 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: Can steel angles be used in outdoor or corrosive environments?

- Yes, steel angles can be used in outdoor or corrosive environments. However, it is important to choose the right type of steel that is specifically designed to withstand corrosion and other environmental factors. Stainless steel angles, for example, are commonly used in such environments due to their high resistance to rust and corrosion. Regular carbon steel angles, on the other hand, may require additional protective coatings or treatments to prevent corrosion in outdoor or corrosive environments.

- Q: How do steel angles contribute to the overall stability of a structure?

- Steel angles contribute to the overall stability of a structure by providing additional strength and support. They are often used as structural members in construction projects to connect and reinforce different components, such as beams and columns. The angles help distribute and transfer loads, improving the structure's resistance to bending, buckling, and other forces. Additionally, their L-shape design allows them to resist shear and torsional stresses, enhancing the overall stability and integrity of the structure.

- Q: How do you prevent warping of steel angles during fabrication?

- To prevent warping of steel angles during fabrication, there are several key measures that can be taken: 1. Proper material handling: Steel angles should be stored, transported, and handled carefully to avoid any bending or warping. They should be stored on a flat surface or rack, ensuring that they are not subjected to excessive pressure or force that could cause deformation. 2. Controlled heating and cooling: During fabrication processes that involve heat, such as welding or cutting, it is crucial to control the temperature and minimize the heat input. Rapid heating or cooling can lead to thermal expansion or contraction, causing warping. Proper preheating and controlled cooling methods, such as using heat sinks or heat-treating processes, should be employed to mitigate the risk of warping. 3. Proper welding techniques: Welding is a critical step in steel fabrication, and improper techniques can contribute to warping. It is essential to use appropriate welding parameters, such as correct amperage, voltage, and travel speed, to ensure a balanced heat distribution across the workpiece. Additionally, employing welding fixtures, clamps, or jigs can help hold the steel angles in place during welding, minimizing distortion. 4. Minimize stress concentration: Sharp corners or abrupt changes in geometry can create stress concentration points, which are prone to warping. It is advisable to avoid sharp corners by using radii or chamfers, which distribute stress more evenly. Furthermore, proper alignment and fit-up of the steel angles before welding can reduce residual stress and potential warping. 5. Post-welding treatments: After welding, it is essential to relieve residual stresses in the steel angles. This can be achieved through post-weld heat treatment or stress-relieving processes, such as annealing or normalizing. These treatments help to reduce internal stresses and minimize the risk of warping. Overall, a combination of proper material handling, controlled heating and cooling, appropriate welding techniques, stress minimization, and post-welding treatments can significantly contribute to preventing warping during the fabrication of steel angles.

- Q: Can steel angles be used for manufacturing safety barriers?

- Yes, steel angles can be used for manufacturing safety barriers. Steel angles are commonly used in construction projects due to their strength and durability. They are particularly suitable for safety barriers as they provide a sturdy framework that can withstand impact and provide protection. Steel angles can be easily welded or bolted together to create a solid and secure barrier. Additionally, steel angles can be galvanized or coated with anti-corrosive materials to enhance their longevity and resistance to environmental factors. Overall, steel angles are an excellent choice for manufacturing safety barriers due to their strength, durability, and versatility.

- Q: Can steel angles be used for equipment racks?

- Yes, steel angles can be used for equipment racks. Steel angles provide structural support and stability, making them suitable for holding heavy equipment and ensuring durability.

- Q: Can steel angles be used for bracing or reinforcement?

- Bracing or reinforcement purposes can be achieved with steel angles. These L-shaped structural steel members, also known as angle irons, are commonly utilized in construction and engineering. Their shape and structural properties make them highly suitable for offering bracing or reinforcement in various structures. To reinforce beams, columns, or trusses and provide added strength and stability, steel angles are used. They can also function as bracing elements to counter lateral loads like wind or seismic forces, thereby preventing structural failure. Moreover, steel angles can be easily installed as they can be welded, bolted, or riveted to other structural members, exhibiting great versatility. The choice of steel angle size and thickness relies on the specific application and load requirements. It is crucial to consult a structural engineer or adhere to applicable building codes and regulations to guarantee appropriate use and installation of steel angles for bracing or reinforcement purposes.

- Q: How do you calculate the second moment of area for a steel angle?

- In order to determine the second moment of area for a steel angle, a step-by-step procedure must be followed. The following guidelines outline how this can be accomplished: 1. Initiate the process by sketching the cross-section of the steel angle on either paper or a CAD software platform. Ensure that all dimensions are accurately labeled. 2. Partition the angle into smaller geometric shapes, such as rectangles and triangles, as these are simpler to calculate the second moment of area for. 3. Compute the individual second moments of area for each geometric shape. The formula employed to determine the second moment of area, also known as the moment of inertia, varies depending on the shape. For rectangles, the formula is (b * h^3) / 12, where b represents the base and h denotes the height. For triangles, the formula is (b * h^3) / 36, with b and h representing the base and height respectively. Adjust the formulas accordingly based on the orientation and positioning of the shapes within the angle. 4. Sum up the individual second moments of area for all the shapes within the angle. If there are any openings or cutouts present, subtract their respective second moments of area from the total. 5. Once the second moments of area have been calculated for all the shapes and adjustments have been made for any cutouts, add them together to obtain the total second moment of area for the steel angle. It is important to emphasize that the second moment of area signifies the resistance of a cross-section to bending. This parameter is critical in structural analysis and design, as it aids in determining the strength and stability of a structural member under applied loads.

- Q: What are the different types of steel angles used in staircases?

- Staircases commonly employ various types of steel angles for different purposes. These angles are selected based on the specific needs of the staircase design. 1. The Equal Leg Angle, which forms a 90-degree angle with legs of equal length, is the most frequently used steel angle in staircases. It is typically utilized for structural support within the framework of the staircase. 2. Unequal Leg Angles, as the name implies, have legs of varying lengths. These angles are employed when one side of the staircase requires more support or when a desired aesthetic appearance is desired. They are commonly found in stair treads, risers, and stringers to enhance stability and strength. 3. L-Shaped Angles are utilized in corner connections of staircases. They consist of one straight leg and another leg perpendicular to it, forming an L shape. These angles are often used in stair handrails, balusters, and brackets to provide reinforcement and support at junctions. 4. Slotted Angles are designed with slots along their length, allowing for easy adjustment and flexibility in component positioning. They are frequently employed in adjustable stair brackets, tread supports, and other elements that may require fine-tuning during installation. 5. Flat Bar Angles, also referred to as flat stock angles, are created by bending flat steel bars to form a right angle. These angles are used to provide additional support and reinforcement in staircases that require extra strength. They are commonly found in heavy-duty stair applications or where increased load-bearing capacity is necessary. Ultimately, the appropriate choice of steel angle for a staircase depends on factors such as load capacity, structural requirements, aesthetic considerations, and the specific design of the staircase. Seeking guidance from a structural engineer or staircase designer can assist in determining the most suitable type of steel angle for a particular staircase project.

- Q: What is the maximum allowable torsional stress for a steel angle?

- Several factors determine the maximum allowable torsional stress for a steel angle, including the specific grade of steel, the dimensions and shape of the angle, and the intended application. Steel angles are commonly used in structural applications, such as supporting beams and frames, and they are designed to withstand various types of stresses, including torsional stress. Engineers typically consult industry standards and codes, such as the AISC Manual or EN 10056, to determine the maximum allowable torsional stress for a steel angle. These standards provide guidelines and formulas for calculating the maximum allowable torsional stress based on properties like the cross-sectional area, moment of inertia, and modulus of elasticity of the steel angle. It is important to note that the maximum allowable torsional stress is usually expressed as a percentage of the steel's yield strength or ultimate tensile strength. This ensures that the angle can safely endure torsional loads without suffering permanent deformation or failure. In practical applications, engineers and designers carefully analyze specific requirements and loading conditions to determine the appropriate maximum allowable torsional stress for a steel angle. They consider factors such as the magnitude and direction of the applied torque, the angle's orientation, and any additional loads or constraints present. Ultimately, the maximum allowable torsional stress for a steel angle is a critical parameter in ensuring the structural integrity and safety of a design. Proper consideration of the steel's properties, industry standards, and specific application requirements is essential for accurate calculations and the selection of an appropriate steel angle capable of effectively resisting torsional stress.

- Q: What is the maximum bending moment for a steel angle?

- The maximum bending moment for a steel angle depends on various factors such as the dimensions, material properties, and loading conditions. It cannot be determined without specific information about the angle and the forces acting on it.

Send your message to us

Equal Angle Steel, American Standard Steel Angles, Carbon Steel Angle Iron

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 35000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords