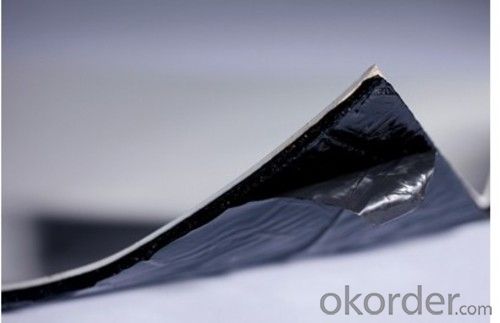

EPDM Waterproofing Rubber Membrane for Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Characteristic:

1.Excellent anti aging performance ,service life up to 50 years.

2.High extension rate,high tensile strength ,small size changes at heat treatment.

3.Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4.Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5.Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6.Convenient application ,solid joint ,no environment pollution.

7.Chemical corrosion resistance ,can be used for special occasions.

8.Good anti-perforated.

Application Range

EPDM waterproof membranes form an effective barrier to liquid water or water vapor in the roof construction for industrial and civil engineering, underground engineering such as subway & tunnel, water conservancy such as water pools & ditch, shelter, grain depot, land filling, dyke, sewage treatment and basement.

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Does a waterproofing membrane require any special cleaning or maintenance procedures?

- Yes, a waterproofing membrane typically requires special cleaning and maintenance procedures to ensure its effectiveness and longevity. Regular inspections, cleaning off debris, and addressing any damage or wear are essential to prevent leaks or deterioration. Additionally, specific cleaning products and techniques may be recommended by the manufacturer or installer to maintain the membrane's performance.

- Q: Does a waterproofing membrane require any special considerations for installation in seismic zones?

- Yes, a waterproofing membrane does require special considerations for installation in seismic zones. Seismic activity can cause significant ground movement and structural vibrations, which can potentially compromise the integrity of the membrane. Therefore, it is crucial to select a membrane that is specifically designed and tested to withstand seismic conditions. Additionally, proper installation techniques and materials, such as reinforced membranes and flexible adhesives, should be used to ensure the membrane remains intact during seismic events.

- Q: Floor tiles on the terrace leak, can be directly on the brick shop SBS coil and then cast the cement?

- 4, SBS linoleum waterproof, when other waterproofing process is not suitable, you can choose SBS linoleum waterproof, and its advantages in: for a larger area and scope, more complex places, no regular terrace can be used, but the disadvantage is that SBS felt Waterproof is not extended, easy to aging, generally used in 3-5 years, and the construction should be very cautious, because the shop linoleum, the use of gasoline to spray the barbecue, it is easy to ignite the surrounding building materials, especially color steel insulation layer and Building insulation wall, are flammable materials, such as ignition, the consequences could be disastrous, so SBS linoleum waterproof as little as possible, with new materials to replace, even when used, be careful, do a good job before and after the construction arrangements.

- Q: Are waterproofing membranes resistant to wind-driven rain?

- Yes, waterproofing membranes are designed to be resistant to wind-driven rain. They are typically made from durable materials that can withstand the impact of rain and are installed to provide a protective barrier against water penetration.

- Q: What materials are commonly used for waterproofing membranes?

- There are several materials commonly used for waterproofing membranes, each with their own unique properties and advantages. Some of the most commonly used materials include: 1. Bitumen: Bitumen is a popular choice for waterproofing membranes due to its excellent waterproofing properties. It is a viscous, black, and sticky substance derived from petroleum, and it is often mixed with polymers to enhance its flexibility, durability, and resistance to UV radiation. 2. PVC (Polyvinyl Chloride): PVC membranes are highly durable and resistant to chemicals, making them suitable for various waterproofing applications. They are easy to install and can withstand extreme temperatures, making them popular for flat roofs and underground structures. 3. EPDM (Ethylene Propylene Diene Monomer): EPDM is a synthetic rubber membrane that is highly flexible and durable. It is resistant to UV radiation, ozone, and extreme temperatures, making it suitable for both above and below-ground applications. EPDM membranes are commonly used for roofs, foundations, and pond liners. 4. TPO (Thermoplastic Olefin): TPO membranes are a blend of rubber and plastic polymers, making them highly flexible, durable, and resistant to UV radiation. They are lightweight and easy to install, making them popular for commercial roofing applications. 5. HDPE (High-Density Polyethylene): HDPE membranes are made from high-density polyethylene and are known for their excellent chemical resistance. They are commonly used for waterproofing underground structures, such as tunnels and basements. 6. Bentonite: Bentonite clay is a natural material that swells when exposed to water, forming a gel-like substance that seals cracks and pores. Bentonite membranes are often used for waterproofing below-ground structures and are particularly effective in preventing water infiltration. 7. Liquid applied membranes: These membranes are typically made from a combination of synthetic polymers and rubber. They are applied as a liquid and form a continuous, seamless, and flexible waterproofing layer when cured. Liquid applied membranes are versatile and can be used for various applications, including roofs, balconies, and foundations. It's important to note that the choice of material depends on the specific requirements of the project, including the type of structure, environmental conditions, and budget. Consulting with a waterproofing professional is recommended to determine the most suitable material for a particular application.

- Q: How thick should a waterproofing membrane be?

- The thickness of a waterproofing membrane can vary depending on the specific application and the type of membrane used. However, a typical thickness range for most waterproofing membranes is between 1.5mm to 3mm. It is important to consult with a professional or follow the manufacturer's recommendations to determine the appropriate thickness for your specific waterproofing needs.

- Q: Can a waterproofing membrane be used in tunnels or underground structures?

- Yes, a waterproofing membrane can be used in tunnels or underground structures. Waterproofing membranes are designed to create a barrier against water penetration, making them effective in preventing water ingress in underground environments. These membranes are commonly used in tunnel construction to protect against moisture and water-related damages.

- Q: Can a waterproofing membrane be used in areas with high levels of moisture and humidity?

- Yes, a waterproofing membrane can be used in areas with high levels of moisture and humidity. Waterproofing membranes are specifically designed to protect surfaces from water penetration, making them ideal for areas with high moisture content. These membranes are typically made from materials like rubber, PVC, or bitumen, which are resistant to water and can effectively prevent water from seeping through. Additionally, some waterproofing membranes also have built-in features such as vapor barriers or breathable properties, allowing them to be used in areas with high humidity levels. However, it is important to choose the right type of waterproofing membrane that is suitable for the specific conditions and requirements of the area to ensure its effectiveness and longevity.

- Q: Can a waterproofing membrane be used in swimming pools or water features?

- Yes, a waterproofing membrane can be used in swimming pools or water features. Waterproofing membranes are often used in these applications to create a barrier between the water and the surrounding structure. This helps prevent water leakage and damage to the structure, ensuring the longevity and durability of the swimming pool or water feature. The membrane is typically applied to the surface of the structure and can be made of various materials such as rubber, PVC, or bitumen. It is important to choose a membrane that is specifically designed for underwater applications to ensure its effectiveness in providing a watertight seal. Additionally, proper installation and regular maintenance of the waterproofing membrane are crucial to ensure its long-term performance.

- Q: Can a waterproofing membrane be used for plant rooms or mechanical spaces?

- Plant rooms or mechanical spaces can benefit from the use of a waterproofing membrane. These areas house various equipment, machinery, and systems, often containing pipes, tanks, and other components that require protection from water damage. A waterproofing membrane serves as a strong and flexible barrier that effectively prevents water infiltration. It can be applied to walls, floors, or ceilings, ensuring the longevity and functionality of the equipment and systems by safeguarding them against water leaks or moisture damage. Furthermore, the application of a waterproofing membrane also serves as a vapor barrier, preventing the accumulation of condensation or humidity that can adversely affect sensitive equipment.

Send your message to us

EPDM Waterproofing Rubber Membrane for Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords