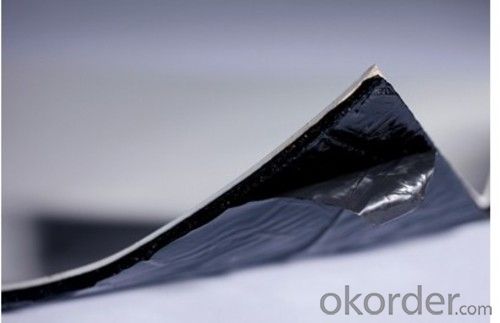

EPDM Waterproofing Membrane Used in Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Characteristic:

1.Excellent anti aging performance ,service life up to 50 years.

2.High extension rate,high tensile strength ,small size changes at heat treatment.

3.Good plant roots penetrability resistance and can be made waterproofing layer of planting roof.

4.Special modified molecular structure ,effectively resolving the current domestic and foreign glue joint problem.

5.Good low temperature flexibility ,and good performance of adapting to ambient temperature changes.

6.Convenient application ,solid joint ,no environment pollution.

7.Chemical corrosion resistance ,can be used for special occasions.

8.Good anti-perforated.

Applicable scope:

1.0mm 1.2mm 1.5mm 1.8mm 2.0mm EPDM waterproof membrane is widely used in roofs, basement, toilet, swimming pool, and all kinds of industry and civil building waterproofing, reservoir, bridge, underground, tunnel and dam waterproofing, especially to the keystone waterproofing projects which is durability, high corrosion resistance and easy deformation.

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used for retaining walls?

- Yes, a waterproofing membrane can be used for retaining walls. Waterproofing membranes are commonly used to prevent water infiltration and protect structures from moisture damage. Applying a waterproofing membrane to a retaining wall can help prevent water seepage, reduce hydrostatic pressure, and extend the lifespan of the wall by preventing water-related deterioration.

- Q: Can a waterproofing membrane be used in areas with extreme weather conditions, such as hurricanes or snowstorms?

- Yes, waterproofing membranes can be used in areas with extreme weather conditions, including hurricanes and snowstorms. These membranes are specifically designed to provide protection against water penetration and are built to withstand harsh weather elements. They are often used in construction projects to ensure the durability and longevity of structures in such environments.

- Q: How does a waterproofing membrane withstand freeze-thaw cycles?

- A waterproofing membrane is designed to withstand freeze-thaw cycles by being made of materials that are resistant to temperature changes and water infiltration. These membranes are typically composed of durable polymers such as polyurethane, polyethylene, or PVC, which have low permeability to water and can resist the expansion and contraction caused by freezing and thawing. During freeze-thaw cycles, water can enter small cracks and pores in a structure. When this water freezes, it expands, exerting pressure on the surrounding materials. This expansion can cause cracks to widen and weaken the structure, leading to water leakage and potential damage. However, a waterproofing membrane acts as a barrier, preventing water from penetrating the structure and reducing the potential for freeze-thaw damage. The membrane is installed on the exterior surface of the structure, forming a seamless and continuous layer that does not allow water to pass through. It adheres tightly to the surface and is flexible enough to accommodate the dimensional changes caused by temperature variations. Moreover, waterproofing membranes are often reinforced with other materials such as fabrics or meshes to enhance their strength and stability. These reinforcements further protect the membrane from damage during freeze-thaw cycles, ensuring its long-term effectiveness. In summary, a waterproofing membrane withstands freeze-thaw cycles by preventing water infiltration and resisting the expansion and contraction caused by freezing and thawing. Its composition, including durable polymers and reinforcements, makes it a reliable barrier against water penetration, reducing the risk of structural damage and maintaining the integrity of the protected surface.

- Q: Are waterproofing membranes resistant to chlorine exposure?

- The resistance of waterproofing membranes to chlorine exposure can vary. Certain membranes are designed to withstand chlorine and are commonly used in areas like pool decks or water treatment facilities where chlorine exposure is expected. These membranes are typically made with materials like PVC or TPO that naturally resist chlorine and can endure prolonged exposure without significant damage. It is important to be aware that not all waterproofing membranes are resistant to chlorine. Some membranes, particularly those made with materials like EPDM or bitumen, may not hold up as well against chlorine and may deteriorate or sustain damage with extended exposure. To ensure a waterproofing membrane lasts and performs well in a chlorine-rich environment, it is vital to choose a membrane specifically designed and tested for chlorine resistance. Seeking guidance from a waterproofing professional or manufacturer can assist in determining the most suitable membrane for the particular chlorine exposure conditions.

- Q: Can a waterproofing membrane prevent mold and mildew growth?

- Yes, a waterproofing membrane can help prevent mold and mildew growth. Mold and mildew thrive in damp and moist environments, and waterproofing membranes create a barrier that prevents water from seeping into the underlying surfaces. By keeping the area dry, the membrane reduces the conditions necessary for mold and mildew to grow. Additionally, some waterproofing membranes are designed with antimicrobial properties, which further inhibit the growth of mold and mildew. However, it is important to note that while a waterproofing membrane can help prevent mold and mildew growth, it is not a foolproof solution. Proper ventilation and maintenance are also crucial in preventing these issues.

- Q: Can a waterproofing membrane be used for balconies and terraces?

- Balconies and terraces can benefit greatly from the application of a waterproofing membrane. This is due to the fact that these areas are constantly exposed to outdoor elements like rain, snow, and sunlight, all of which can lead to the accumulation of moisture and the deterioration of the underlying structure. To prevent water penetration and subsequent damage, it is highly recommended to utilize a waterproofing membrane. By acting as a barrier, this protective layer prevents water from seeping through the surface, thus avoiding potential leaks, mold growth, or structural harm. Not only does this guarantee the long-lasting and sturdy nature of the balcony or terrace, but it also provides a wide range of options in terms of types and materials. This flexibility allows for the selection of the most suitable waterproofing membrane that aligns with the specific requirements of the balcony or terrace.

- Q: Can a waterproofing membrane be installed under tile or other flooring materials?

- Yes, a waterproofing membrane can be installed under tile or other flooring materials. Waterproofing membranes are commonly used in areas where moisture may be present, such as bathrooms, kitchens, and basements. These membranes act as a barrier, preventing water from seeping through the floor and causing damage to the underlying structure. They are typically applied directly onto the substrate before the tile or flooring material is installed. This ensures that any water or moisture that may penetrate the flooring is redirected and prevented from reaching the subfloor. By installing a waterproofing membrane, you can protect your floors and extend their lifespan while ensuring a dry and moisture-free environment.

- Q: Are waterproofing membranes suitable for historical preservation projects?

- Waterproofing membranes can be suitable for historical preservation projects, depending on the specific circumstances and goals of the project. Waterproofing membranes are designed to provide a protective barrier against water infiltration, which can help to prevent damage to historical structures caused by moisture. In some cases, historical buildings may have existing waterproofing systems that are deteriorated or no longer effective. In these situations, the use of modern waterproofing membranes can be a viable option to protect and preserve the structure. These membranes can be installed discreetly, without altering the original appearance or architectural integrity of the building. However, it is crucial to approach the use of waterproofing membranes in historical preservation projects with caution. The potential impact on the authenticity and historical value of the structure must be carefully evaluated. Some historical buildings may have unique construction methods or materials that require specialized preservation techniques. In such cases, alternative preservation methods that do not involve the use of membranes may be more appropriate. Additionally, it is important to consider the long-term consequences and maintenance requirements of waterproofing membranes. Some membranes may have a limited lifespan, and periodic inspections and maintenance may be necessary to ensure their continued effectiveness. This ongoing maintenance should be factored into the overall preservation plan and budget. Ultimately, the decision to use waterproofing membranes in historical preservation projects should be based on a thorough assessment of the specific needs and characteristics of the building, as well as the preservation objectives. Consulting with preservation experts, architects, and engineers can help to determine the most suitable approach for each unique project.

- Q: Can a waterproofing membrane be applied to wood surfaces?

- Yes, a waterproofing membrane can be applied to wood surfaces. There are various types of waterproofing membranes available on the market, such as liquid membranes or sheet membranes, that can be specifically designed for wood surfaces. These membranes are typically made of materials like rubber, asphalt, or polyurethane, which provide a protective barrier against water and prevent moisture from penetrating the wood. The waterproofing membrane is applied to the wood surface using different methods, depending on the product, such as brushing, rolling, or spraying. Applying a waterproofing membrane to wood surfaces can help prolong the lifespan of the wood, prevent rotting or warping, and protect it from water damage. However, it is important to ensure proper surface preparation and follow the manufacturer's instructions for application to achieve the best results.

- Q: Can a waterproofing membrane be installed on bathroom or shower walls?

- Yes, a waterproofing membrane can be installed on bathroom or shower walls to protect the underlying structure from water damage.

Send your message to us

EPDM Waterproofing Membrane Used in Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords