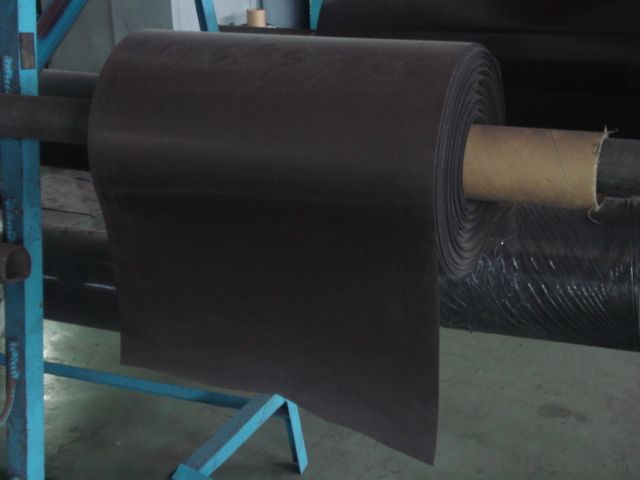

EPDM Waterproof Rubber Membrane for Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product description

The flexible roofing system has been mature history for several years in the world, especially in the large workshop, warehouse, logistics and other roof has been widely used. Its structure is simple and clear: pressure plate structure of gas isolation - insulation waterproof, each function of each level divided the whole roof; waterproof layer for the whole roof from the erosion of rainwater, so waterproof material excellent in the flexible roofing.

Our EPDM waterproofing membrane, is one of the world's advanced waterproof material, it not only has three Yuan rubber weather resistance, good aging resistance; lap joint can also be hot air welding, overcomes three EPDM coiled material adhesive construction is complex, so that the joint is more solid water quality is more reliable.

Product features

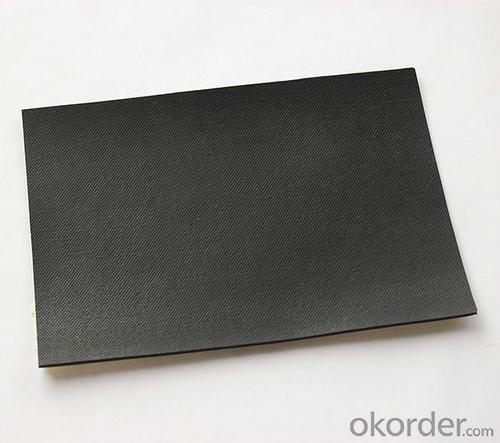

The physical and mechanical properties of stability, durability and anti ageing capacity is good, its oil and solvent resistance and general-purpose chloroprene rubber be roughly the same.

1 Good heat resistance, cold resistance, can be in (-60-150 C) within the scope of use.

2 Extension and rate very high tear strength, shrinkage cracking of buildings or a strong ability to adapt.

3 The proportion of light (0.90~0.97), the appearance of uniform quality, has good flexibility and elasticity.

4 Good weldability, materials can be directly welded, is conducive to ensure weld quality. After welding to form an integral waterproof layer.

5 Good dimensional stability, heat shrinkage is small, the deformation is small, keep a good state during construction.

6 Environmental protection type. Does not produce harmful substances in the production, construction and use of the process, and can be recycled, does not produce construction waste.

Application arrange

Applicable to all kinds of roofing, basement, tunnel, building waterproof engineering; civil and industrial building roofs and underground engineering, municipal, bridges, storage tank,

Waterproof subway, tunnel, dam engineering, especially suitable for durability, corrosion resistance requirements and easy deformation of the key waterproof engineering.

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used on brick surfaces?

- Yes, a waterproofing membrane can be used on brick surfaces. The membrane can be applied to protect the brick from moisture, water infiltration, and potential damage caused by water absorption.

- Q: Does a waterproofing membrane have any impact on the appearance of a surface?

- The appearance of a surface can be affected by a waterproofing membrane. When it is applied to a wall or floor, the membrane acts as a barrier to prevent water or moisture from entering. This process typically involves adding a coating or layer that can change the texture or shine of the surface. Occasionally, the membrane might result in a slight color variation or darken the surface. Nevertheless, there are transparent or colorless waterproofing membranes accessible that have minimal impact on the appearance of the surface. Ultimately, the extent to which the appearance is influenced depends on the specific type of waterproofing membrane utilized and the desired aesthetic result.

- Q: Can a waterproofing membrane be used for storage tanks or containment areas?

- Yes, a waterproofing membrane can be used for storage tanks or containment areas. Waterproofing membranes are designed to provide a barrier against water or other liquid penetration, making them suitable for applications where containment is required. These membranes are typically made from materials such as rubber, PVC, or bitumen, which are known for their water-resistant properties. They can be applied to the interior or exterior surfaces of storage tanks or containment areas to prevent leaks and protect the structures from moisture damage. Additionally, waterproofing membranes can also help to prevent the growth of mold or mildew, ensuring a safe and hygienic environment for stored materials or liquids.

- Q: Does a waterproofing membrane require any special tools for installation?

- Yes, installing a waterproofing membrane typically requires special tools such as a trowel, brush or roller for application, utility knife for cutting the membrane, and a heat gun for seam sealing.

- Q: Can a waterproofing membrane be used on iron surfaces?

- Yes, a waterproofing membrane can be used on iron surfaces. Waterproofing membranes are typically made of materials such as rubber, bitumen, or polyurethane, which are designed to create a barrier against water and moisture. These membranes can adhere to various surfaces, including iron, and provide protection against water infiltration. When applied correctly, a waterproofing membrane can effectively seal and waterproof iron surfaces, preventing corrosion and extending the lifespan of the material. It is important to choose a waterproofing membrane that is compatible with iron and follow the manufacturer's instructions for proper installation and maintenance.

- Q: Is a waterproofing membrane resistant to freeze-thaw cycles?

- Yes, a waterproofing membrane is resistant to freeze-thaw cycles. This is because the membrane is designed to prevent the penetration of water, which can expand and contract during freeze-thaw cycles. The membrane acts as a barrier, preventing water from seeping into the structure and causing damage due to freezing and thawing. Additionally, waterproofing membranes are typically made from materials that are flexible and able to withstand temperature fluctuations without losing their effectiveness.

- Q: The difference between waterproof linoleum and waterproofing membrane

- Waterproof membrane is mainly used for building walls, roofs, as well as tunnels, highways, landfills, etc., to resist the external rain, groundwater leakage can be curled into a roll of flexible building materials, as the basis for engineering And no leakage between the building connection, the entire project is the first waterproof barrier, the entire project plays a vital role. The main products are asphalt waterproofing membrane and polymer waterproofing membrane.

- Q: Can waterproofing membranes be used on concrete countertops?

- Concrete countertops can indeed benefit from the application of waterproofing membranes. These membranes are specially crafted to thwart the infiltration of water and can be utilized on diverse surfaces, including concrete. By opting for a waterproofing membrane on a concrete countertop, one can effectively safeguard it against water harm, staining, and possible structural concerns. Furthermore, these membranes can augment the countertop's resilience and lifespan by averting moisture-induced problems, such as cracking or warping. It is imperative to verify that the selected waterproofing membrane is concrete-compatible and appropriate for countertop use.

- Q: Can waterproofing membranes be used on concrete pipes?

- Concrete pipes can indeed utilize waterproofing membranes. These membranes are frequently employed to thwart the ingress of water and safeguard concrete structures against moisture-induced harm. Like any other concrete structure, concrete pipes are vulnerable to water infiltration, which can result in decay and a shortened lifespan. By applying a waterproofing membrane to concrete pipes, a barrier against water can be established, thus averting potential complications such as leaks, cracks, and corrosion. Typically, the membrane is administered to the exterior of the pipe, forming a protective layer that thwarts water from permeating the concrete. This measure contributes to prolonging the pipes' lifespan and guaranteeing their long-standing durability.

- Q: Can a waterproofing membrane be applied to curved surfaces?

- Indeed, it is possible to apply a waterproofing membrane to surfaces that have curves. Specifically designed methods and products are accessible for adhering to and covering such surfaces. These membranes possess flexibility, allowing them to be molded or stretched in order to conform to the shape of the curved surface, guaranteeing a tight and secure seal. While the application process may demand additional care and attention to ensure appropriate adhesion and coverage, the effective waterproofing of curved surfaces is certainly achievable.

Send your message to us

EPDM Waterproof Rubber Membrane for Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords