EPDM Waterproofing Membrane for Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

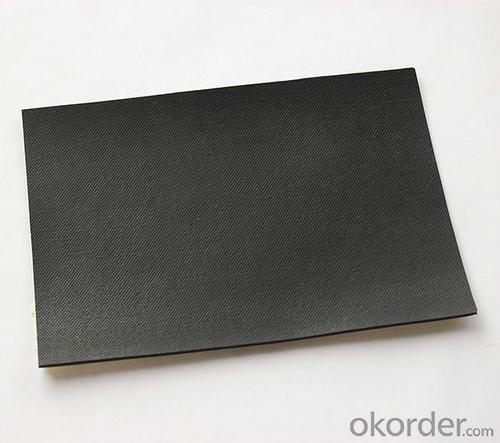

1.EPDM Waterproof Membrane / Roofing Material / Sheets Roofing

2.High tensile strength.

3.Good elongation.

4.UV resistant.

5.Anti-corrosion.

Product instruction

EPDM waterproof membrane is made from ternary ethylene-propylene rubber. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Features

1) Excellent weather-ability, durability and size stability

2) Good adaptability to high and low temperature, UV resistant and anti-corrosion

3) High tensile strength and good elongation, accommodating to structure movement

4) Easy installation, solid joint, and no environmental pollution

5) Good rooting penetration resistance

6) Service life up to 50 years

Application

1) Roofs, Basement, Toilet

2) Industrial and civil building waterproofing

3) Geo-synthetic liner for swimming pool, channels, irrigation system

4) Especially suit for projects with high requirements in durability, anti-corrosion and deformation

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Is a waterproofing membrane resistant to hydrocarbons or oils?

- Yes, a waterproofing membrane is generally resistant to hydrocarbons or oils. The materials used in waterproofing membranes, such as bitumen or synthetic polymers, are typically designed to have high resistance to various chemicals, including hydrocarbons and oils. This resistance helps to ensure that the membrane remains effective in preventing water penetration even in the presence of these substances. However, it is important to note that the specific resistance level may vary depending on the type and quality of the waterproofing membrane. It is always recommended to consult the manufacturer or supplier to determine the exact resistance capabilities of a specific waterproofing membrane.

- Q: Can a waterproofing membrane be used in swimming pools or other water features?

- Yes, a waterproofing membrane can definitely be used in swimming pools or other water features. In fact, it is highly recommended to use a waterproofing membrane in these areas to prevent water leakage and damage. A waterproofing membrane acts as a barrier between the water and the surrounding structures, ensuring that the water is contained within the pool or water feature. It helps to prevent water seepage, which can cause structural damage and lead to costly repairs. Additionally, a waterproofing membrane also helps to protect the pool or water feature from the harsh chemicals used for water treatment, ensuring its longevity and durability. Therefore, using a waterproofing membrane is a crucial step in the construction or renovation of swimming pools or other water features to ensure their functionality and longevity.

- Q: Can a waterproofing membrane be used on different types of surfaces, such as concrete, wood, or metal?

- Yes, a waterproofing membrane can be used on different types of surfaces such as concrete, wood, or metal. Waterproofing membranes are designed to create a barrier that prevents water from penetrating the surface and causing damage. They are versatile and can adhere to various materials, making them suitable for different applications. For concrete surfaces, a waterproofing membrane can be applied to protect against water intrusion and to prevent moisture-related issues such as cracks, corrosion, or mold growth. It can be used on concrete foundations, basements, or retaining walls to ensure they remain dry and structurally sound. When it comes to wood, a waterproofing membrane acts as a protective layer that prevents water absorption, warping, rotting, or decay. It can be applied to exterior surfaces like decks, balconies, or fences to enhance their lifespan and maintain their integrity. In the case of metal surfaces, a waterproofing membrane can be used to prevent rusting and corrosion caused by water exposure. It creates a barrier that seals out moisture, protecting metal roofs, gutters, or other metal structures from water damage. It is important to note that different types of waterproofing membranes may be more suitable for specific surfaces. For example, liquid-applied membranes can be easily applied on irregular surfaces like concrete, while sheet membranes may be more appropriate for flat or smooth surfaces. It is advisable to consult with a professional or manufacturer to determine the most suitable waterproofing membrane for a specific surface and application.

- Q: Can a waterproofing membrane be used in tunnels?

- Yes, a waterproofing membrane can be used in tunnels. Waterproofing membranes are commonly used in tunnel construction to prevent water infiltration and protect the tunnel structure from damage caused by moisture. These membranes are designed to provide a barrier against water, keeping the tunnel dry and secure.

- Q: Does a waterproofing membrane require any special considerations for installation in high-humidity areas?

- Special considerations are required when installing a waterproofing membrane in high-humidity areas. The presence of high humidity can impact the membrane's performance if not addressed properly during installation. Here are some important points to keep in mind: 1. Moisture management is crucial: Before installing the waterproofing membrane, it is essential to control moisture levels in the area. Thoroughly drying the surface and resolving any existing moisture issues or leaks is necessary. 2. Vapor barriers are beneficial: To prevent moisture from seeping through the membrane, it is advisable to install a vapor barrier underneath. This is particularly important in consistently humid environments. 3. Adequate ventilation is key: To avoid excessive moisture buildup, proper airflow and ventilation systems should be in place. This promotes drying and prevents condensation, which can compromise the integrity of the waterproofing membrane. 4. Choose the right membrane: Not all waterproofing membranes are suitable for high-humidity areas. It is crucial to select a membrane specifically designed and recommended for such environments. Look for membranes with high moisture resistance and durability. 5. Professional installation is recommended: Proper installation techniques are vital for the long-term performance of the waterproofing membrane. In high-humidity areas, it is advisable to hire experienced contractors who have worked in similar conditions. By considering these factors, you can ensure that the waterproofing membrane effectively protects against moisture in high-humidity areas.

- Q: Are waterproofing membranes suitable for stadium structures?

- Waterproofing membranes are well-suited for stadium structures. Stadiums are exposed to different weather conditions, such as rain, snow, and humidity, which can potentially harm the structure if proper waterproofing measures are not taken. By providing a protective layer that prevents water infiltration, waterproofing membranes safeguard the stadium from moisture-related problems like leaks, mold, and corrosion. Water accumulation on large roof areas and expansive seating areas is common in stadium structures, making waterproofing essential. Membranes can be applied on various surfaces, such as concrete, metal, and wood, offering a versatile and effective waterproofing solution for stadiums. Furthermore, waterproofing membranes offer durability and longevity, which is crucial for stadiums that experience heavy usage and constant exposure to the elements. They are designed to withstand thermal expansion and contraction, as well as UV radiation, ensuring long-term protection for the structure. Moreover, architects and engineers can customize waterproofing membranes to meet specific design requirements, seamlessly integrating them into the stadium's overall aesthetic. These membranes come in various colors, textures, and finishes, allowing them to blend with the surrounding materials and enhance the stadium's visual appeal. In conclusion, waterproofing membranes are a reliable and effective solution for protecting stadium structures from water damage. They provide durability, versatility, and customization options, making them suitable for any stadium construction or renovation project.

- Q: Are waterproofing membranes suitable for residential applications?

- Yes, waterproofing membranes are suitable for residential applications. They are commonly used in various areas of residential construction, such as basements, foundations, roofs, bathrooms, and balconies, to prevent water penetration and protect the building structure from moisture damage. Waterproofing membranes provide a barrier against water, preventing it from seeping into the structure and causing issues like mold, rot, or structural damage. These membranes are typically made of materials like bitumen, PVC, EPDM, or polyurethane, which are highly effective in repelling water. In residential constructions, waterproofing membranes are installed during the building process or as a part of renovation projects. They can be applied as a liquid coating or in the form of sheets that are laid down and adhered to the surface. These membranes create a seamless and durable barrier that can withstand the test of time. Additionally, waterproofing membranes offer various benefits for residential applications. They help maintain a dry and comfortable living environment by preventing water leaks and dampness. This, in turn, protects the integrity of the building materials, prolongs the lifespan of the structure, and reduces the risk of costly repairs. Furthermore, waterproofing membranes can also enhance energy efficiency by reducing moisture-related heat loss or gain. By preventing water infiltration, they help maintain consistent temperatures inside the house, resulting in lower energy consumption and utility bills. Overall, waterproofing membranes are an excellent choice for residential applications. They provide reliable protection against water damage, improve the longevity of the structure, and contribute to a healthier and more energy-efficient living environment.

- Q: What is the difference between pressure-sensitive self-adhesive waterproofing membrane and sbs asphalt waterproofing membrane?

- 1, from the product level (1) pressure-sensitive self-adhesive waterproof membrane is a new type of product, is the fourth generation of products, and Sbs asphalt waterproofing membrane is the second generation of products, so that the former is a new product, then the effect is certainly better than

- Q: Can a waterproofing membrane be used for stadiums or arenas?

- Yes, a waterproofing membrane can be used for stadiums or arenas. Waterproofing membranes are commonly used in construction to prevent water infiltration, and they can be applied to the roofs, walls, or foundations of stadiums or arenas to protect them from water damage. These membranes are designed to withstand harsh weather conditions and provide long-lasting protection, making them suitable for large-scale structures like stadiums or arenas.

- Q: Can a waterproofing membrane be used on plastic block surfaces?

- Indeed, it is possible to utilize a waterproofing membrane on surfaces composed of plastic blocks. These membranes are specifically engineered to serve as a safeguard against moisture, effectively hindering water infiltration. Similar to any other type of surface, plastic blocks are prone to water-related harm if not adequately shielded. By applying a waterproofing membrane, one can successfully seal and safeguard the plastic blocks, thus thwarting water permeation and potential destruction. To achieve optimal outcomes, it is crucial to select a waterproofing membrane that harmonizes with plastic materials and adhere to the manufacturer's application guidelines.

Send your message to us

EPDM Waterproofing Membrane for Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords