EPDM Waterproofing Membrane Roll Used in Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Brief Introduction:

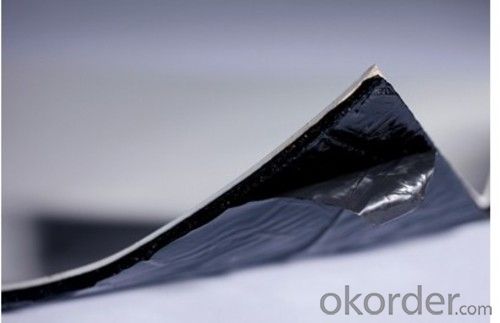

This waterproof membrane is made from ternary ethylene-propylene rubber. Weadopts the world advanced equipment of cold feeding extrusion and continuous valcanization technology.

With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or crack under normal building movement.

Specification:

Tensile Strength N/CM | Normal temperature: 60 ; 60°C: 30 |

Breaking Elongation % | Normal temperature: 400 ; -20°C: 10 |

Tear Resistance N | 20 |

Impermeability, 30 min no leakage | 0.3Mpa |

Low Temperature Bending °C | -20 |

Heating Shrinking mm | Extension: 2 Shrink: 4 |

Heat Resistance (80°C×168h) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:70 |

Alkali resistance (10% ca (oh)2 solution,normal temperature ×168h)) | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Synthetic aging | Tensile Strength % : 80 ; Keeping rate of adhesive breaking:80 |

Characteristic:

1)Good flexibility, creep properties and malleability, and the superior adapting ability to the deformation of the primary stress generated.

2). Tight adhesion between waterproof layer and basic layer, no channeling water. Having self healing ability after piercing.

3).Operation without heating. And possessing the reliability of pasting by itself with super strong connection of sheet materialand adhesion of same base.

4). Convenient and safe operation, no pollution to the environment.

Application:

1),Roofs, Basement, Toilet

2),Industrial and civil building waterproofing

3),Geosynthetic liner for swimming pool, channels, irrigation system

4),Especially suit for projects with high requirements in durability, anti-corrosion anddeformation

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can a waterproofing membrane be used in conjunction with fire protection systems?

- Yes, a waterproofing membrane can be used in conjunction with fire protection systems. While the primary function of a waterproofing membrane is to prevent water penetration, it can also act as a barrier to protect against fire. Some waterproofing membranes have fire-resistant properties, allowing them to withstand high temperatures and prevent the spread of fire. However, it is essential to ensure that the specific waterproofing membrane chosen is compatible and approved for use with the fire protection system in question.

- Q: Elastomer modified asphalt waterproofing membrane for what purpose? Need to pay attention to a few things?

- Second, the construction quality Full adhesion to prevent wrinkles or hollowing; semi-adhesive attention to the unbonded to under fire, so that the membrane close to the base surface; empty shop attention around the adhesive, and pressurized. Hot melt adhesive, with the fire to be appropriate to the surface of the coil is not subject to black, avoid slow baking. Winter construction selection of low temperature flexibility than the construction temperature of 10 ℃ lower temperature products, and the coil stored at 0 ℃ above the place before use into the scene, handling to prevent throwing throw.

- Q: Can a waterproofing membrane be used on concrete?

- Concrete can indeed benefit from the use of a waterproofing membrane. In fact, it is a popular technique employed to shield concrete structures from the harmful effects of water and moisture. A waterproofing membrane is a slender layer of material that is carefully placed on the concrete surface, serving as a barrier against water and moisture. This membrane can be crafted from a variety of materials such as bitumen, rubberized asphalt, polyurethane, or acrylic. It is typically administered in either liquid or sheet form, effectively attaching itself to the surface and forming a continuous impermeable coating. This coating, in turn, prevents water from infiltrating the concrete, thereby thwarting the possibility of deterioration, cracks, and other types of damage. Waterproofing membranes are extensively employed in a wide range of concrete applications, including basements, foundations, roofs, and any other structures that are exposed to water or moisture.

- Q: Are waterproofing membranes suitable for historical buildings?

- Yes, waterproofing membranes can be suitable for historical buildings. These membranes provide an effective solution for preventing water penetration and damage to the structure, helping to preserve the integrity and longevity of the building. However, it is essential to consider the specific requirements and characteristics of the historical building and select an appropriate membrane that is compatible with its materials and architectural features. Additionally, any waterproofing work should be done with sensitivity and care to ensure it does not compromise the historical value or aesthetics of the building.

- Q: What is the difference between polymer waterproofing membrane and cross film waterproofing membrane?

- he strong cross-over film of the product is a high-strength HDPE film formed by the cross-laminating process. The film and the like have the same vertical and transverse elongation ratio. The coil does not send deformation, more beautiful and waterproof reliable.

- Q: Can a waterproofing membrane be used in residential construction?

- Yes, a waterproofing membrane can be used in residential construction. Waterproofing membranes are commonly used in various areas of a residential property, such as roofs, basements, bathrooms, and foundations. These membranes are designed to prevent water penetration and protect the structure from moisture-related damages. By installing a waterproofing membrane, homeowners can ensure that their property remains dry and free from water leaks, which can lead to mold growth, structural deterioration, and other costly issues. There are various types of waterproofing membranes available in the market, including sheet membranes, liquid membranes, and self-adhering membranes, each with its own advantages and suitability for specific applications. Consulting with a professional contractor or architect can help determine the most appropriate waterproofing membrane for a particular residential construction project.

- Q: Can a waterproofing membrane be used for an underground structure?

- Yes, a waterproofing membrane can be used for an underground structure. Waterproofing membranes are designed to provide a protective barrier against water infiltration, making them suitable for preventing moisture buildup and potential damage in underground structures such as basements, tunnels, or subways.

- Q: Can a waterproofing membrane be used on precast stone block surfaces?

- Precast stone block surfaces can benefit from the application of a waterproofing membrane. These membranes are frequently utilized to safeguard a variety of surfaces, including precast stone blocks, from water infiltration and moisture harm. The purpose of these membranes is to establish a barrier that prevents water from seeping into the surface and causing problems like mold, decay, or structural deterioration. By applying a waterproofing membrane to precast stone block surfaces, their durability and lifespan can be improved by shielding them from water-related difficulties. However, it is crucial to diligently adhere to the manufacturer's instructions and ensure that the chosen waterproofing membrane is appropriate for the specific type of precast stone block surface being treated.

- Q: Is a waterproofing membrane resistant to punctures or tears?

- Yes, a waterproofing membrane is designed to be resistant to punctures or tears. It is typically made from durable materials such as PVC, TPO, or EPDM, which are known for their strength and resistance to damage. These membranes undergo rigorous testing to ensure their ability to withstand various environmental conditions and potential sources of punctures or tears, such as sharp objects or heavy foot traffic. Additionally, some waterproofing membranes come with reinforcement layers or added protection to further enhance their puncture and tear resistance. However, it is important to note that while waterproofing membranes are highly resilient, they are not completely impervious to damage. Proper installation, regular maintenance, and avoiding unnecessary stress or impact on the membrane can help maximize its longevity and performance.

- Q: Can a waterproofing membrane be used on terrazzo surfaces?

- Yes, a waterproofing membrane can be used on terrazzo surfaces. Terrazzo is a durable and versatile flooring material made from a combination of marble, granite, quartz, or glass chips embedded in a cementitious or epoxy matrix. While terrazzo is generally resistant to water, it is not completely waterproof and can absorb moisture if left untreated. Applying a waterproofing membrane on terrazzo surfaces can help protect it from water damage, staining, and discoloration. The membrane acts as a barrier, preventing water and other liquids from seeping into the terrazzo, thus enhancing its longevity and maintaining its aesthetic appearance. It is important to ensure that the waterproofing membrane is compatible with the terrazzo material and is applied according to the manufacturer's instructions for optimal effectiveness.

Send your message to us

EPDM Waterproofing Membrane Roll Used in Roofing Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords