EPDM Rubber Membrane Waterproof Prodcuts Roll

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Waterproof Membrane

Product Instruction:

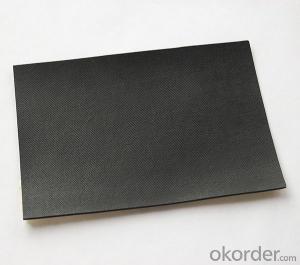

EPDM rubber waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Product Features:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications:

-Roof, basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications:

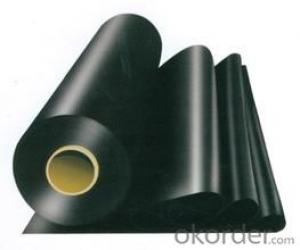

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

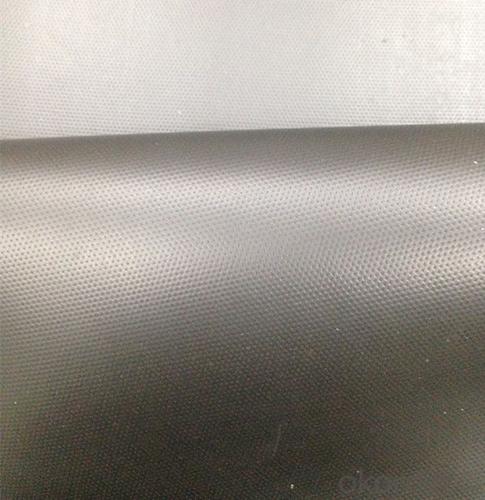

Photos:

- Q: Can a waterproofing membrane be used in areas with high humidity?

- Yes, a waterproofing membrane can be used in areas with high humidity. In fact, high humidity can often contribute to the need for waterproofing as it can lead to moisture buildup and potential water damage. Waterproofing membranes are designed to create a barrier that prevents water from seeping through surfaces, such as walls or floors. They can effectively protect against moisture and water infiltration, which is particularly important in high humidity areas where the risk of water damage is greater. By applying a waterproofing membrane, you can significantly reduce the likelihood of mold, mildew, and other moisture-related issues in these environments.

- Q: Can a waterproofing membrane be used on PVC roofs?

- PVC roofs, commonly found in commercial and residential buildings, are known for their durability and resistance to weathering. However, like all roofing materials, they can develop leaks and cracks over time. To combat this issue, a waterproofing membrane can be applied to PVC roofs. This membrane, such as EPDM or TPO, is flexible and can easily adhere to the PVC surface, forming a seamless and watertight barrier. It is crucial to ensure that the chosen waterproofing membrane is compatible with PVC roofs and to carefully follow the manufacturer's instructions for proper installation. Additionally, regular maintenance and inspections are highly recommended to promptly detect and address any potential problems before they worsen.

- Q: Can a waterproofing membrane be used in elevator pits?

- The utilization of a waterproofing membrane in elevator pits is possible. Due to their subterranean location, elevator pits are susceptible to water intrusion from sources like groundwater or moisture. A waterproofing membrane acts as a safeguarding layer that is applied to the walls and floor of the elevator pit, effectively obstructing the passage of water. This protective barrier prevents water from causing harm to vital components of the elevator system, such as electrical equipment, pumps, and hydraulic systems. Implementing a waterproofing membrane in elevator pits substantially diminishes the likelihood of water damage and corrosion, ensuring the elevator's safe and efficient operation.

- Q: Are waterproofing membranes resistant to impact damage?

- Waterproofing membranes offer protection against water infiltration and typically resist impact damage to varying degrees. The level of impact resistance depends on the specific membrane type and quality. Generally, high-quality waterproofing membranes are designed to endure normal impacts and stresses that occur during installation and use. They are manufactured using durable materials, like modified bitumen, rubberized asphalt, or synthetic polymers, which enhance their strength and resilience. Although waterproofing membranes can withstand minor impact damage, they are not completely impervious to more significant impacts. Dropping heavy objects or sharp objects falling onto the membrane can potentially cause punctures or tears, compromising the integrity of the waterproofing system. This can result in water infiltration and potential structural issues. To enhance impact resistance, additional protective measures can be taken, such as installing a protective layer or using reinforced membranes. These extra layers or reinforcements provide an additional barrier against impact damage, ensuring the long-term performance and durability of the waterproofing system. In conclusion, while waterproofing membranes generally resist impact damage, it is crucial to handle them with care during installation and avoid unnecessary impacts that could potentially compromise their integrity.

- Q: Can a waterproofing membrane be used on flat roofs?

- Flat roofs can indeed benefit from the use of a waterproofing membrane. This method is widely recognized as one of the most effective and commonly used techniques for achieving waterproofing on flat roofs. The membrane itself is a thin material that is carefully applied to the roof's surface in order to prevent any water from seeping through. Typically constructed from durable and flexible substances like synthetic rubber or modified bitumen, the membrane is designed to withstand harsh weather conditions and offer long-lasting protection. By installing the membrane in overlapping layers, a continuous barrier is created that effectively seals the roof, preventing any water leakage into the building. Additionally, it is worth noting that waterproofing membranes can also provide insulation and energy efficiency advantages, which further contributes to their popularity in flat roof applications.

- Q: Can a waterproofing membrane be used for a hospital?

- A hospital can indeed utilize a waterproofing membrane. In construction projects, waterproofing membranes are frequently employed to safeguard the integrity of building materials by preventing moisture infiltration. In a hospital environment, where hygiene and infection control hold paramount importance, maintaining a dry and clean surrounding is crucial to hinder the growth of mold, mildew, and bacteria. A waterproofing membrane can serve as a barrier against water and moisture, thus averting any potential harm to the structure and ensuring a secure and healthy environment for patients, staff, and visitors. Moreover, specific areas of a hospital, such as operating rooms or laboratories, where the likelihood of spills or water exposure is higher, can also benefit from the use of waterproofing membranes. In summary, the incorporation of a waterproofing membrane in a hospital contributes to upholding a high standard of cleanliness, safety, and durability within the facility.

- Q: Can a waterproofing membrane be used on tunnels with seismic protection systems?

- Tunnels equipped with seismic protection systems can indeed benefit from the use of a waterproofing membrane. It is strongly advised to employ such a membrane in order to avoid water infiltration and subsequent harm to the tunnel's integrity. Seismic protection systems are engineered to absorb and dissipate the seismic energy released during an earthquake, guaranteeing the tunnel's safety and stability. However, these systems do not provide any defense against water ingress. By incorporating a waterproofing membrane, the tunnel can be shielded from potential water leaks and seepage, which can result in reinforcement corrosion, concrete deterioration, and overall structural impairment. It is crucial to opt for a waterproofing membrane specifically designed for tunnel use, taking into account qualities such as flexibility, durability, and resistance to seismic-induced movement. Moreover, precise detailing and installation techniques must be employed to ensure a seamless and efficient waterproofing system that complements the tunnel's seismic protection measures.

- Q: Can a waterproofing membrane be used in areas with high water pressure?

- Yes, a waterproofing membrane can be used in areas with high water pressure. Waterproofing membranes are designed to withstand and prevent water penetration, making them suitable for use in areas where there is high water pressure. However, it is important to ensure that the membrane chosen is specifically rated and designed to handle the specific water pressure levels in order to ensure its effectiveness and durability.

- Q: Can a waterproofing membrane be used for shower installations?

- Yes, a waterproofing membrane can be used for shower installations. In fact, it is highly recommended to use a waterproofing membrane in shower installations to prevent water from seeping into the walls, floors, or other areas where it can cause damage. A waterproofing membrane acts as a barrier, preventing water from infiltrating the surrounding areas. This is particularly important in showers where water is constantly being used and splashed around. By using a waterproofing membrane, you can ensure that your shower area remains watertight and protected against any potential water damage.

- Q: Can a waterproofing membrane withstand heavy rain or water pressure?

- Yes, a waterproofing membrane is designed to withstand heavy rain and high water pressure. It is specifically engineered to create a barrier that prevents water from penetrating through, ensuring the protection and integrity of the underlying structure.

Send your message to us

EPDM Rubber Membrane Waterproof Prodcuts Roll

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords