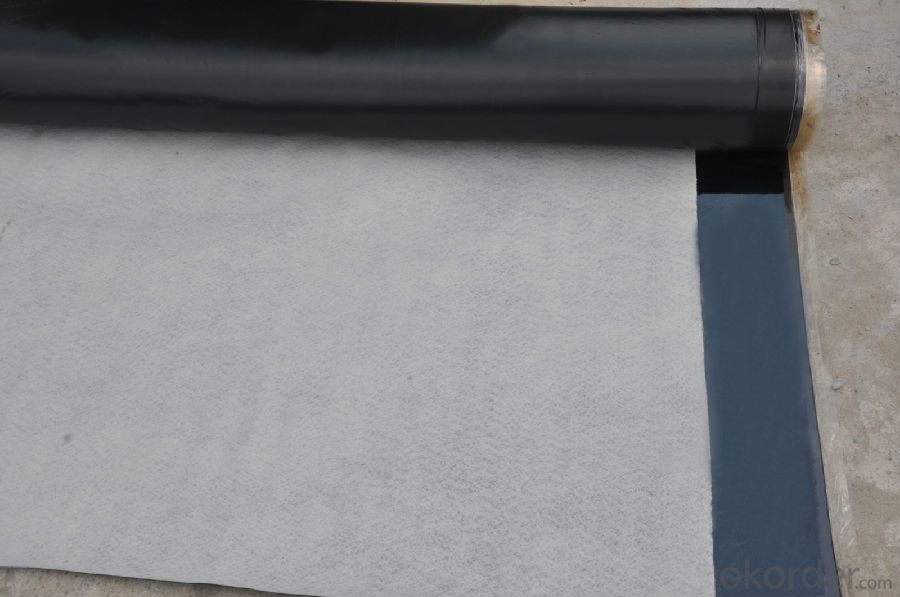

EPDM Rubber Waterproofing Membrane Leakage Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction for EPDM Waterproofing Membrane:

Waterproof membrane for roof adopt the international advanced level cold feed extrusion continuous vulcanization process for the integration of production equipment and technology so that the system density of products is better and the products have no bubble sooth surface, no performance difference between vertical and horizontal.

Application of EPDM Waterproofing Membrane:

This product is suitable for all kinds of industrial and civil building roof, basement, reservoirs, ponds, sewage treatment system, civil air

defense projects, channel, girder factory waterproofing. Especially for highways, railways and culverts, bridges and other water impermeable

concrete bridge deck construction.

Specification of EPDM Waterproofing Membrane:

No. | Item | Unit | Standard Request | |

1 | Variation in Dimension | Thickness | % | ±10 |

Width | % | ±1 | ||

Length | % | No Negative Value | ||

2 | Tensile Strength at Break(Normal Temperature) | Mpa | ≥7.5 | |

Tensile Strength at Break(60ºC) | Mpa | ≥2.3 | ||

3 | Elongation at Break(Normal Temperature) | % | ≥450 | |

Elongation at Break(-20ºC) | % | ≥200 | ||

4 | Tearing Strength | KN/m | ≥25 | |

5 | Water Impermeability(30min) | * | 0.3Mpa Impermeability | |

6 | Bend Temperature | ºC | ≤-40 | |

7 | Heating Expansion/Shrinkage | Expansion | mm | ≤2 |

Shrinkage | mm | ≤4 | ||

8 | Hot Air Aging 80ºC x168h | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥70 | ||

9 | Property of Anti Alkali 10% Ca(OH)²x 168h normal temperature | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥80 | ||

10 | Elongation 40%,500x102 | * | No Crack | |

11 | Artificial Aging | Unchanging of Tensile Strength at Break | % | ≥80 |

Unchanging of Tearing Strength | % | ≥70 | ||

Appearance of 100% elongation | * | No Crack | ||

FAQ of Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q: Can waterproofing membranes be used on utility tunnels?

- Utility tunnels, which are often exposed to moisture and water infiltration, can benefit from the use of waterproofing membranes. These membranes serve to safeguard the tunnel structure against water damage and ensure its longevity. Their purpose is to establish a barrier between the structure and its surroundings, effectively halting the seepage of water into the tunnel. Typically crafted from materials like bitumen or synthetic polymers, these membranes possess remarkable resistance against water penetration. By applying them to the walls, floors, and ceilings of utility tunnels, they provide comprehensive protection against water-related issues, including leaks, cracks, and deterioration. Furthermore, waterproofing membranes also play a vital role in upholding the integrity of utility tunnels by thwarting the influx of harmful substances such as chemicals or pollutants. In conclusion, the application of waterproofing membranes to utility tunnels represents a highly effective means of guaranteeing their long-term durability and functionality.

- Q: Can a waterproofing membrane be installed on a concrete foundation?

- Installing a waterproofing membrane on a concrete foundation is indeed a common practice. This is done to prevent water infiltration and safeguard the structure from moisture-related harm. Typically, the membrane is applied to the exterior surface of the foundation walls, serving as a barrier against water and moisture. The type of membrane used can vary, ranging from liquid-applied to sheet membrane or a combination of both, depending on the project's specific requirements. Its purpose is to act as a protective layer, preventing water from penetrating the foundation and causing issues like dampness, mold growth, and structural decay. By incorporating a waterproofing membrane into a concrete foundation, homeowners and builders can guarantee the structure's long-term durability and integrity.

- Q: Can a waterproofing membrane be used for elevator shafts and stairwells?

- Yes, a waterproofing membrane can be used for elevator shafts and stairwells. Elevator shafts and stairwells are areas that are prone to moisture and water infiltration, especially in below-grade or high-moisture environments. Waterproofing membranes are designed to provide a barrier against water penetration and protect the structure from potential damage caused by moisture. When applied correctly, a waterproofing membrane can effectively prevent water from seeping into elevator shafts and stairwells, keeping them dry and free from water-related issues such as mold growth, deterioration of materials, and structural damage. These membranes are typically made from durable materials such as modified bitumen, PVC, or rubberized asphalt, which offer excellent waterproofing properties. It is important to choose a waterproofing membrane that is specifically designed for below-grade or high-moisture applications. These membranes should have high resistance to hydrostatic pressure, be capable of bridging cracks, and have long-term durability to withstand the constant exposure to moisture. Additionally, the installation of a waterproofing membrane in elevator shafts and stairwells should be done by trained professionals who have experience in waterproofing systems. This will ensure that the membrane is installed correctly, providing an effective barrier against water infiltration. In summary, a waterproofing membrane is a suitable solution for elevator shafts and stairwells as it can effectively prevent water penetration and protect the structure from moisture-related issues.

- Q: Can a waterproofing membrane be used for theaters or concert halls?

- Yes, a waterproofing membrane can be used for theaters or concert halls. Waterproofing membranes are commonly used in construction projects to prevent water infiltration and protect the building from water damage. The membrane is applied to surfaces such as walls, floors, and roofs, creating a barrier that prevents water from seeping through. In theaters and concert halls, where the protection of the building structure and equipment is crucial, waterproofing membranes can be highly beneficial. They can help prevent water damage to sensitive equipment, such as audiovisual systems, lighting fixtures, and musical instruments. Additionally, a waterproofing membrane can help maintain a dry and comfortable environment for both performers and audience members by preventing water leakage and moisture buildup. Overall, using a waterproofing membrane in theaters or concert halls can help ensure the longevity and functionality of the building while providing a safe and enjoyable experience for everyone involved.

- Q: Can a waterproofing membrane be used for a hospital?

- A hospital can indeed utilize a waterproofing membrane. In construction projects, waterproofing membranes are frequently employed to safeguard the integrity of building materials by preventing moisture infiltration. In a hospital environment, where hygiene and infection control hold paramount importance, maintaining a dry and clean surrounding is crucial to hinder the growth of mold, mildew, and bacteria. A waterproofing membrane can serve as a barrier against water and moisture, thus averting any potential harm to the structure and ensuring a secure and healthy environment for patients, staff, and visitors. Moreover, specific areas of a hospital, such as operating rooms or laboratories, where the likelihood of spills or water exposure is higher, can also benefit from the use of waterproofing membranes. In summary, the incorporation of a waterproofing membrane in a hospital contributes to upholding a high standard of cleanliness, safety, and durability within the facility.

- Q: Can a waterproofing membrane be used for below-grade parking structures?

- Yes, a waterproofing membrane can be used for below-grade parking structures. Waterproofing membranes are commonly used in construction to prevent the ingress of water and protect structures from water damage. In the case of below-grade parking structures, which are underground or partially underground, there is a higher risk of water infiltration due to the surrounding soil and groundwater. Waterproofing membranes are applied to the exterior surfaces of the structure, creating a barrier that prevents water from seeping through the walls and floors. These membranes are typically made of materials such as bitumen, rubberized asphalt, PVC, or polyurethane, which are highly resistant to water penetration. Additionally, some membranes may also have additional properties like crack-bridging capabilities or protection against chemicals or gases. It is important to consult with a qualified engineer or waterproofing specialist to determine the most suitable membrane for a specific below-grade parking structure, taking into consideration factors such as soil conditions, hydrostatic pressure, and local building codes.

- Q: Can a waterproofing membrane be used in historic buildings?

- Yes, a waterproofing membrane can be used in historic buildings. Historic buildings often face challenges related to moisture infiltration and water damage due to their age and construction materials. Waterproofing membranes are a common solution to prevent water seepage and protect the building's structural integrity. However, it is important to choose a waterproofing membrane that is compatible with the historic building's materials and construction methods to ensure its preservation and adherence to historical authenticity. Additionally, any waterproofing work done on a historic building should be carried out by professionals with expertise in historic preservation to ensure proper installation and minimal impact on the building's historical value.

- Q: Can a waterproofing membrane be used on zinc surfaces?

- Yes, a waterproofing membrane can be used on zinc surfaces. Zinc is a durable and corrosion-resistant material commonly used in various applications, including roofing and cladding. Applying a waterproofing membrane on zinc surfaces can provide an additional layer of protection against water intrusion and moisture damage. It can help prevent leaks, extend the lifespan of the zinc surface, and maintain its overall integrity. However, it is important to ensure that the waterproofing membrane is compatible with zinc and specifically designed for such applications. It is recommended to consult with a professional or manufacturer to determine the best waterproofing solution for zinc surfaces.

- Q: Can a waterproofing membrane be used in schools or educational buildings?

- Yes, a waterproofing membrane can definitely be used in schools or educational buildings. Waterproofing membranes are designed to prevent water penetration and protect the building structure from moisture damage. In educational buildings, where a large number of students and staff gather, it is crucial to maintain a safe and healthy environment. Waterproofing membranes can be used in various areas such as basements, roofs, walls, and foundations to prevent water leakage, dampness, and mold growth. By installing a waterproofing membrane, schools can ensure the longevity of their buildings, protect valuable equipment and resources, and provide a comfortable learning environment for students and staff.

- Q: Can a waterproofing membrane be used in residential construction?

- Residential construction can indeed utilize a waterproofing membrane. These membranes find common usage in different parts of a residential property, such as roofs, basements, bathrooms, and foundations. Their purpose is to prevent water from penetrating and causing damage due to moisture. By opting for a waterproofing membrane, homeowners can ensure that their property remains dry and free from water leaks. This is crucial because such leaks can result in mold growth, structural deterioration, and other costly problems. The market offers a variety of waterproofing membranes, such as sheet membranes, liquid membranes, and self-adhering membranes, each with its own advantages and suitability for specific applications. Consulting with a professional contractor or architect can assist in determining the most suitable waterproofing membrane for a particular residential construction project.

Send your message to us

EPDM Rubber Waterproofing Membrane Leakage Protection

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords