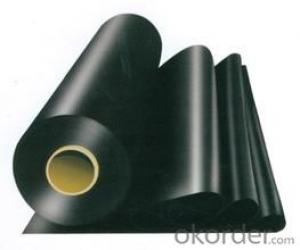

EPDM Rubber Membrane Waterproof Roll 1.2m, 2m, 4m

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 210000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPDM Rubber Waterproof Membrane

Product Instruction:

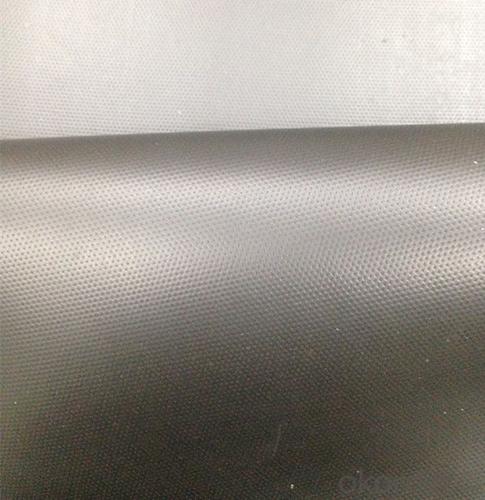

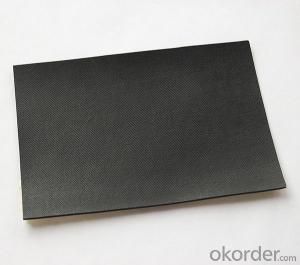

EPDM waterproof membrane is made from ternary ethylene-propylene rubber,which is designed for waterproofing of exposed and non-exposed applications. EPDM waterproof membrane is of high elasticity among high polymer waterproof materials and becomes a world-popular waterproofing material.

CNBM own the wold-advanced equipment of cold feeding extrusion and continuous vulcanization technology. With the best performance among high polymer waterproof materials, EPDM is of exceptional elasticity and will not split or cracked under normal building movement.

Product Features:

-Excellent weather-ability, durability and size stability

-Good adaptability to high and low temperature, UV resistant and anti-corrosion

-High tensile strength and good elongation, accommodating to structure movement

-Easy installation, solid joint, and mo environmental pollution

-Good rooting penetration resistance

-Service life up to 50 years

Applications:

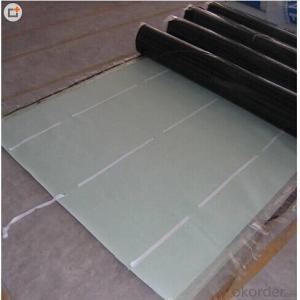

-Roof, basement, tunnel, pond liner, dam

-Industrial and civil building waterproofing

-Geosynthetic liner for fish ponds, swimming pools, channels, irrigation system

-Especially suitable for projects with high requirement in durability, anti-corrosion and deformation

Specifications:

-Width of roll: 1.2m, 2m, 4m

-Length of roll: 20m, 30m or customized

-Thickness of membrane: 1.2mm, 1.5mm, 2mm

-Type: vulcanized EPDM or welding EPDM

-Application: roof, basement, pond, lake, swimming pool, steel structure roofing, underground, tunnel, etc

FAQ:

1. Is your EPDM waterproof membrane the real rubber?

Yes, our EPDM membrane is made from top quality rubber, which is imported from America. We support samples for testing, or testing in our factory.

2. How's your products quality?

Our EPDM is with the top quality at home and abroad. Our quality is much higher than Chinese standard. Our product is widely used in Chinese Central government projects. And it's also accpted by customers all over the world, such as EU, USA, Astrulia, etc.

3. What's the service life of your EPDM membrane?

The service life of our EPDM membrane is more than 50 years.

4.What's your MOQ?

Our MOQ is 3000M2.

5. What's your product ability of EPDM membrane?

We own the largest EPDM production line in China. Our product ability of EPDM membrane reaches 2 million square meter per year.

Photos:

- Q: Coil waterproof roofing requirements

- 3, More than 50, the polymer membrane R is greater than 20

- Q: Can a waterproofing membrane be used in conjunction with concrete repair or restoration?

- Indeed, it is common practice to utilize a waterproofing membrane in conjunction with concrete repair or restoration. It is advisable to employ a waterproofing membrane as a safeguarding layer on top of repaired or restored concrete surfaces. This is due to the potential compromise of the original concrete's waterproofing properties during the repair or restoration process. Application of a waterproofing membrane guarantees the continued protection of the repaired or restored concrete against water infiltration, thereby preventing additional harm and deterioration. Moreover, the waterproofing membrane contributes to bolstering the overall strength and lifespan of the concrete structure.

- Q: Can waterproofing membranes be used for planter boxes?

- Planter boxes can indeed benefit from the use of waterproofing membranes. These membranes are specifically designed to keep water from entering surfaces and can be applied to a variety of materials like wood, concrete, and metal. When a waterproofing membrane is applied to the inside of a planter box, it acts as a shield, safeguarding the material against water damage and extending the planter box's lifespan. This is especially advantageous for wooden planter boxes because it prevents the wood from decaying or deteriorating over time. Moreover, the waterproofing membrane also aids in retaining moisture within the planter box, preventing water leakage and ensuring that plants receive an adequate water supply for healthy growth. Ultimately, the use of waterproofing membranes for planter boxes enhances their durability and performance, making them a popular choice for both indoor and outdoor gardening.

- Q: Are waterproofing membranes resistant to salt damage?

- Yes, waterproofing membranes are generally resistant to salt damage. Waterproofing membranes are designed to provide a barrier against moisture and water infiltration, and this includes protection against saltwater. Saltwater can be highly corrosive and can cause damage to various materials, but waterproofing membranes are typically made from materials that are resistant to the corrosive effects of salt. These membranes are often composed of materials such as reinforced PVC, modified bitumen, or EPDM rubber, which have proven to be durable and reliable in saltwater environments. Additionally, waterproofing membranes are commonly used in applications such as basements, swimming pools, and marine structures, where they are exposed to saltwater regularly. Therefore, it can be concluded that waterproofing membranes are generally resistant to salt damage and can provide effective protection against saltwater infiltration.

- Q: Can a waterproofing membrane be used for vehicular traffic areas?

- Vehicular traffic areas can benefit from the use of a waterproofing membrane. These membranes are specifically designed to create a barrier that prevents water from seeping through and causing damage to surfaces. In areas like parking decks or driveways, it is crucial to protect the underlying structure from water infiltration, which can lead to corrosion, deterioration, and expensive repairs. By utilizing a waterproofing membrane that is specifically designed for vehicular traffic, the surface can be effectively safeguarded from water damage, as well as other potential contaminants such as oil and chemicals. These membranes are typically more durable and capable of withstanding the weight and impact of vehicles, ensuring long-lasting protection. Furthermore, certain waterproofing membranes even offer slip-resistant properties, making them suitable for areas where vehicles require traction. Nevertheless, it is important to seek guidance from a professional to determine the appropriate waterproofing membrane and installation method for specific vehicular traffic areas, taking into account factors such as traffic volume, load capacity, and climate conditions.

- Q: What is the recommended temperature range for applying a waterproofing membrane?

- The recommended temperature range for applying a waterproofing membrane typically varies depending on the specific product being used. However, in general, it is advisable to apply the membrane within a temperature range of 50°F to 90°F (10°C to 32°C). This temperature range ensures optimal bonding and curing of the membrane, allowing for effective waterproofing. It is important to follow the manufacturer's instructions and guidelines for the specific product being used, as they may provide more specific temperature recommendations based on their formulation and application process. Additionally, it is crucial to consider the ambient temperature and conditions during application, as extreme temperatures or weather conditions can affect the performance and effectiveness of the waterproofing membrane.

- Q: Can a waterproofing membrane be used on terraces or patios?

- Terraces and patios can benefit greatly from the application of a waterproofing membrane. To avoid water damage and leakage, it is highly recommended to use this protective layer in these areas. Given that terraces and patios are exposed to different weather conditions, such as rain and snow, moisture can easily seep into the underlying structure. To counteract this issue, a waterproofing membrane acts as a barrier, preventing water from infiltrating the surface and safeguarding the integrity of the terrace or patio. This solution not only extends the lifespan of the structure but also prevents costly repairs in the future. Moreover, the use of a waterproofing membrane contributes to the creation of a more comfortable and functional space, as it eliminates the risk of water accumulation and potential slip hazards. All in all, investing in a high-quality waterproofing membrane is a wise choice for those seeking to protect their terrace or patio from water damage.

- Q: Can a waterproofing membrane be used in historical or heritage buildings?

- Indeed, historical or heritage buildings can utilize a waterproofing membrane. Nevertheless, prior to implementing any waterproofing solution, it is imperative to take into account the specific requirements and sensitivities associated with these types of structures. Historical or heritage buildings often possess distinctive architectural characteristics, materials, and construction methods that necessitate preservation and safeguarding. When employing a waterproofing membrane in historical or heritage buildings, it is of utmost importance to choose a product that is compatible with the existing materials and will not cause any harm or modification to the structure. It is advisable to seek guidance from a professional architect or preservation specialist with expertise in working with historical buildings. This will ensure that the chosen waterproofing membrane is appropriate for the specific needs of the building. Furthermore, it is vital to consider the visual impact of the waterproofing membrane on the building's appearance. Historical or heritage buildings frequently showcase unique architectural details and façades that contribute to their character and value. Hence, the selection of the waterproofing membrane should be done with great care to ensure that it does not detract from the building's historical significance or visual allure. In conclusion, while it is possible to employ a waterproofing membrane in historical or heritage buildings, it should be done with caution. The utmost consideration should be given to the building's materials, construction techniques, and aesthetic worth to guarantee that the waterproofing solution does not compromise the structure's integrity or historical importance.

- Q: Does a waterproofing membrane require any special precautions during storage?

- Yes, a waterproofing membrane requires special precautions during storage. It should be stored in a dry, cool, and well-ventilated area, away from direct sunlight and extreme temperatures. It should be kept in its original packaging or wrapped properly to prevent any damage or exposure to moisture. Additionally, it is important to avoid storing it near any sharp objects or chemicals that could potentially cause punctures or degradation of the membrane. Regular inspection and rotation of stock is also recommended to ensure the membrane remains in optimum condition.

- Q: SBS waterproofing membrane sub-class I and II when to use what level to use a secondary level

- For the PE film (aluminum), color sand, shale, fine sand and other four categories; width: 1000mm, 10m long, 15m two specifications; thickness: polyester felt coil 3mm, 4mm, 5mm; fiberglass membrane 3mm, 4mm; glass fiber reinforced polyester felt 5mm Scope: Widely used in industrial and civil construction of the roof, basement, bathroom and other waterproofing works and roof gardens, roads, bridges, tunnels, parking lots, swimming pools and other projects waterproof and moisture. Deformation of the larger project recommended the use of excellent extension of the polyester tire products, other buildings should choose a relatively economical glass fiber products. So look at the temperature and then choose.

Send your message to us

EPDM Rubber Membrane Waterproof Roll 1.2m, 2m, 4m

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 210000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords