High Standard Solid Oak Flooring

- Loading Port:

- Dalian Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 x 20'GP m²

- Supply Capability:

- 40*40GP m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Solid Oak Flooring:

1. CE&FSC Approved

2. Custom Design

3. White oak

4. Excellent Quality and Service

5. Solid wood floor& Engineered wood floor

Product name: Solid Oak Flooring

Species |

oak |

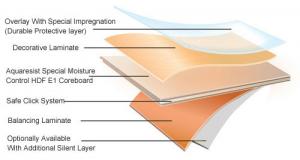

Construction |

Solid hardwood CD Grade

|

Surface effect |

UV Lacquered, stained colour, brushed

|

Bevel | 1mm micro bevel/ can be adjusted according to requirements |

Joint System | T&G |

Moisture content | 9%-11% |

Size |

size: R.L.300-1200x125x18mm(average length 700mm) Other size selection: 57,70,83,90,120,125,130.150 180mm width

|

Certificate | CE/FSC certificate |

Packing |

white Neutral box or according to client Requirement

|

Packaging & Delivery:

Packaging Detail: 1. Carton Box 2. Carton Box on pallet 3. Wrap film packaging

Delivery Detail: About 45-60days

- Q: We had some damage to kitchen floor which homeowners insurance is covering cost to replace. Flooring company just out with samples of engineered hardwood, but after she left I notice it says commercial flooring on the sample board. What is the difference between commercial and residential engineered hardwood? this is Armstrong, Beckford plank.

- Commercial flooring is usually much more heavy-duty (and expensive) than residential flooring.

- Q: All my boards are in 3ft lengths. Do I need to cut them to various lengths before starting? What lengths should I cut them in? Does it look weird having a 3ft borad then a 8 inch board? Please help!

- you dont want back to back seams looks bad just cut every other board in half

- Q: Wood floors and solid wood flooring price difference? Which brand is good

- Now the floor is still very good. At that time to buy some of the floor of their house, and now still very grateful to their home.

- Q: What is the difference (advantages/disadvantages) between hardwood, engineered, and laminated flooring?

- Both engineered wood and laminate have glue in them. They don't wear well in areas with humidity, lots of traffic or areas that need to be washed. However, laminate is very inexpensive and decent engineered wood is about half way in price between hardwood and laminate. For the longest life of a good looking, problem free floor it's best to spend the extra money and get hardwood. Stands up to traffic (even pre-finished) much better and can look great for 20 years or more with just simple dry mopping. (You don't want to vacuum any wood surface unless you have to, as it scratches: laminate in particular doesn't hold up to this well at all). Even though it costs more, it is the best value especially if you ever want to sell the home. What you need to do is look for sales at Lumber Liquidators, Lowes, Home Depot etc. Often, you can get great hardwood on sale for the same cost as the imitations, you just may have to wait a couple of months of checking the websites and local stores for the good sales.

- Q: I am planning to install engineer wood floor over concrete in Corona, California without the moisture barrier. Anyone here done the same with no problem? thanks.

- i would seal the concrete and then install.......check ur warranty it probably says u void the warranty with no barrier..... lic. gen. contractor

- Q: How can i say that hardwood and engineered wood floors are really different with each other?

- Engineered wood is a multi layered wood similar to plywood. The bottom layers usually made of a pine and not the top layer which can be any other type of wood such as oak maple bamboo etc. True hardwood is solid throughout. Engineered is structurally sound and very dimensional.. True hard wood can be resanded several times in standard cases. Engineered wood can be resanded once at best. You can usually use engineered wood on slab ( but there are cautions you must follow). It can be glued or made into a floating floor in most cases. True hardwood holds it s value better in a house . Any questions you can e mail me through my avatar. GL

- Q: All Of The Down Stairs In My House Has Hardwood Floors.(Engineered Wood) But Every time I Clean The Floors They Get Foot prints On Them SO Quickly and I Cant Stand Looking At Those Foot Prints Any More. What Is A Good Product That I Could Use To Clean The Floors. I Really Need Help.

- Sand it all down and re-finish it with a good sealing varnish. That will stop dirt sticking.

- Q: What are the major differences between solid hardwood flooring & engineered hardwood flooring? Also, what is the best to use in high traffic areas and non-high traffic areas; like the living room or dinning room?

- I used to fit hardwood floors for 6 years, The main difference is you can keep sanding back hardwood floors when they start to look old or get damaged, they are more expensive but they will last a lifetime if well maintained, Worth every penny if you got the money, good for use in heavy traffic areas, some engineered hardwood flooring doesn't have much hardwood on it, sometimes just a thin layer on the top, so you might not be able to refurbish it, worth asking about before you make your choice. It really depends on who you choose with engineered hardwood flooring because it seems to be quite different from company to company.hope this is some help.

- Q: So I've been considering to get rid of my old carpet floor and install new hardwood flooring. I just get lost in the research from learning about the different types? I'm reading about engineered wood flooring and it looks like a good match. Does anyone have any personal experience from using it?Thanks.

- Yes, I fitted some oak engineered wood to our hallway a few years ago. It is fairly easy to do for a competent DIYer (me), and quite attractive. Far superior to that plastic covered cardboard known as laminate. I had just one issue:- The main watercock for the house is under the front of the hallway but I solved the problem of accessing it by fitting a couple of brass pull-up rings into the wood in that area.

- Q: Can someone tell me what is best for a house and why? What are advantages and disadvantages?Thanks

- Real wood floors are thick, they can be refinished many times, of course you won't live that long. Engineered wood floors can be refinished a few times, and is all you need. Laminate floors, can not be refinished...When they start looking tacky (8-10 yrs) you replace them or carpet over top. If you are going to keep your house, go for real wood or engineered floors, and before you buy, Ask about the refinishing angle, just to make sure.

1. Manufacturer Overview

| Location | Fushun, China |

| Year Established | 2008 |

| Annual Output Value | Above US$ 5 Million |

| Main Markets | 60.00% North America 30.00% Western Europe 10.00% Domestic |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Dalian |

| Export Percentage | 90% |

| No.of Employees in Trade Department | 2-5 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 20,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | Average; Low |

Send your message to us

High Standard Solid Oak Flooring

- Loading Port:

- Dalian Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 x 20'GP m²

- Supply Capability:

- 40*40GP m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords