Yongsen Ecological Floor With High Quality

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Brief Description

The use of renewable wood as the base material (with fast-growing poplar wood), to protect the ecological environment from damage. The production process of the fiber factor material evenly into the floor, so that the material has a more stable ecological substrate.

2、Material properties

Material properties and characteristics

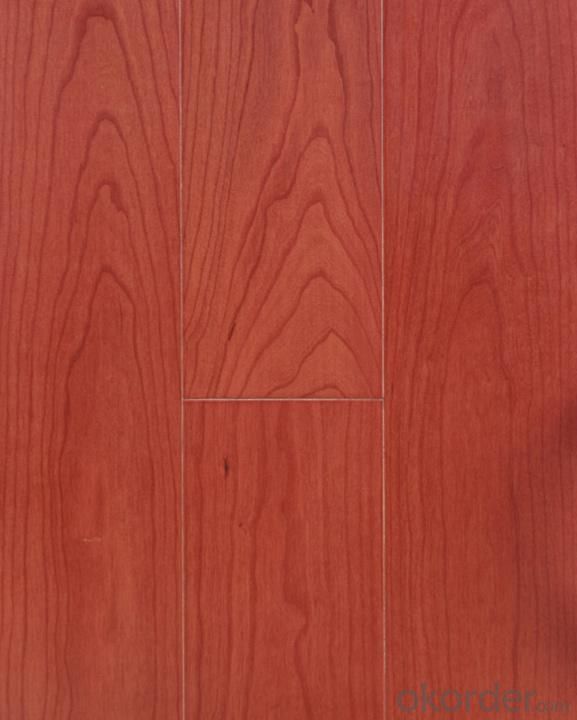

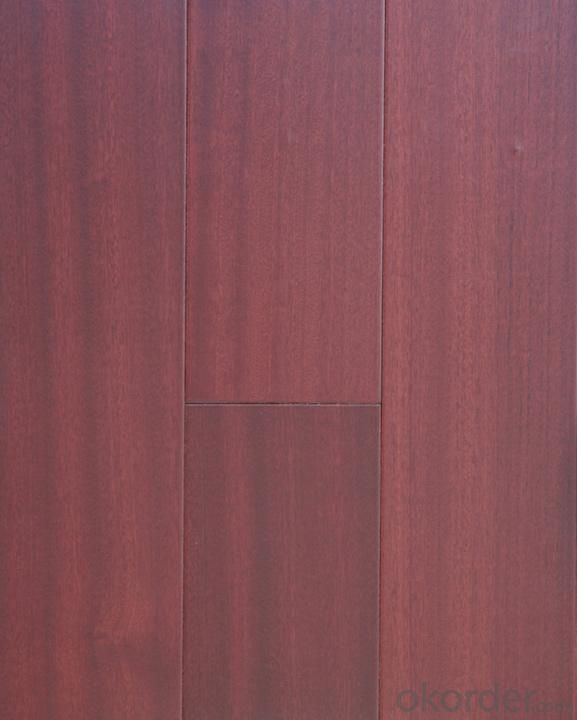

The wood with luster; raw material when there is n pleasant smell, usually no special smell and taste; texture staggered, fine and uniform structure; is the finest solid wood flooring materials. Wood weight to very heavy (gas dry density 1.07g/cm3), dry shrinkage is very big; strength is high (the tensile strength 76.1Mpa, bending strength of 128.9 Mpa). The heartwood golden brown to reddish brown, shiny. Material stability, wear resistance. Geographical environment and climate characteristics of the material itself has a unique aesthetic and textured, dark stripes and glossy, and sapwood distinguishable. In the structure, the wood is very resistant to decay, and the wear resistance is good, and it has good weather resistance. Air dry density 0.61-0.99g/ cubic centimeters and modified wood drying after yellowish brown or dark brown, hard materials, slightly oily, stability is very good,and good natural decay .

3、Parameter

Material: disc beans

Origin: Zhejiang

Style: Modern

Standard: ISO90001

Applicable scope: bedroom

Pattern: Wood

Special purpose: wear resistant

Plate finish: good

Surface shape: paint

Residual depression: no

Formaldehyde release rate: E1

Resistance: good

Wear layer thickness: 3cm

Abrasion resistance: good

Fading (stage): 1

Floor thickness: 18mm

Color: Red

Specifications: 910*122*18

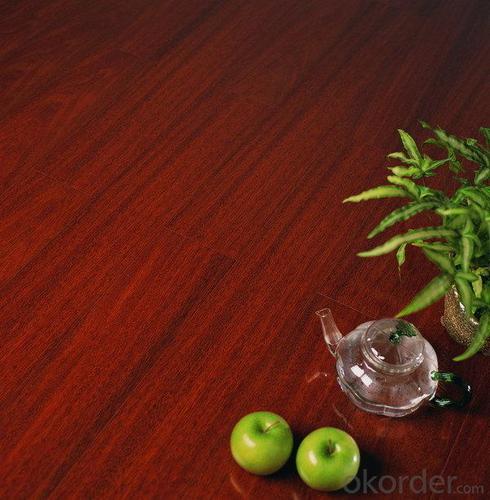

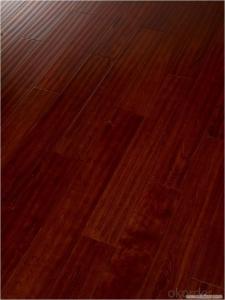

4、Reference pictures

- Q: The floors in my house look like dark wooden planks and at each end are 2 sets of nails (the way they are supose to look). The head of the nails are about the size of maybe a dime and have the sides sanded so there are no rough edges. Can someone tell me what the name of this flooring is?

- There are two types of hardwood flooring: Engineered flooring is manufactured in a manner similar to plywood, where three or five thin sheets (plies) of wood are laminated (glued) together in a crisscross formation for strength. A top layer (veneer) of hardwood is added as a finished top layer. Engineered flooring is available as strips or planks. Strips are 3 or less in width. Planks are over 3 wide. Engineered floors are very stable and can be installed on any grade level. Although engineered wood floors are manufactured through a laminating process, they are not the same as a laminate floor. Longstrip flooring Parquet flooring Solid floors are cut from solid pieces of wood and milled to standard specifications. The flooring can be installed as planks or strips. A longstrip board is constructed of individual slats glued together end to end to form strips. The strips are then installed as tongue and groove. Parquet flooring is normally a 12x 12 square consisting of narrow strips of wood. The parquet tiles, often of varying finishes, are arranged in geometric patterns. Some wood flooring is pre-finished, others will require finishing and sealing. Many wood floors can also be refinished. A surface stain can be removed and re-stained. Penetrating stains have in essence become part of the wood and are permanent. Check the manufacturer’s specifications about refinishing. Whichever wood floor you choose, you install it using one of these methods: Nail down — attached to a wood subfloor with flooring nails. Staple down — attached to a wood subfloor with a pneumatic stapler. Glue down — engineered floors are applied to the subfloor with trowel and adhesive. Floating — tongue and groove floor planks are glued together. Rather than fastened to the subfloor, the floor rests on a pad between the floor and subfloor. as far as the wood you would need to provide more info becides Dark wooden planks

- Q: Which is the best between engineered hardwood floors and natural hardwood floors?

- I prefer solid real hardwood flooring. In my opinion the finish on site solid floors look the best when completed.

- Q: What are the benefits of solid wood flooring decoration

- The texture of Fraxinus mandshurica is clear, the decoration is good, and the material is also selected.The indicators are poor, but the price is cheaper. Factory or store to deal with the product has a one-year warranty period, in the warranty period of warpage, variable table, dry, manufacturers or shops should be responsible for the return. The causes of these defects, is generally not because of wood drying or drying method is backward, water wood drying after high rate or level differences, and drying quality is the general consumers can not detect.

- Q: What are the classification of solid wood flooring

- Wood floor can be divided into two types according to shape:The strip wood floor lath width is 50-150 mm, to 20-30 mm thickness, section processing joint into groove shape, convenient fixation and installation. The advantages of strip wood floor laying patterns can choose, not very strict requirements on the flat ground, but the process more difficult operation and is rough.The parquet wood floor it is in advance according to certain patterns and specifications, will be a few pieces (four pieces) strip of tongue and groove type wood floor assembled into a square wooden floor, wooden floor enterprises use mouth bar specifications of length 150-380 cm, width up to 90 mm, the thickness of not more than 25 mm, 250 x 50 general specifications ~ 60 x 12 ~ 22 and 300 ~ 60 x 50 x 12 ~ 22 mm. Including senior painting spell wood floor. The advantages of parquet wood floor is a guarantee, the assembling quality of convenient construction, at the same time to fight mosaic plate is paved with various patterns, the Dutch pattern more. But on the ground level higher, otherwise it will immediately become warped.

- Q: Does buffing engined hardwood floors really work? Could it take out scratches and slight water damage?

- Engineered flooring can be treated just like regular hardwood flooring.... UP TO A POINT. Engineered flooring is a product made up of a thin veneer of the preferred wood applied to a plywood backing or base. You can do anything to this veneer that you would do to a solid hardwood, BUT you will be limited to how aggressive and how many times you can do it by the thickness of the veneer. You will eventually wear though the veneer and into the substrate. So unless the water damage has delaminated the flooring, slight sanding and buffing will help remove the damage provided you do not go too far

- Q: What kind of wood floor? How to choose?

- The main factors affecting the price of solid wood flooring is wood species, all grades of trees are. In addition, the solid wood floor in the choice of the time and should pay attention to color, knots are.

- Q: All Of The Down Stairs In My House Has Hardwood Floors.(Engineered Wood) But Every time I Clean The Floors They Get Foot prints On Them SO Quickly and I Cant Stand Looking At Those Foot Prints Any More. What Is A Good Product That I Could Use To Clean The Floors. I Really Need Help.

- we use pledge hardwood floor cleaner on ours..... s great

- Q: I want to home, not too expensive. Want to buy (fragrant) two winged bean. I do not know Taizhou, Changzhou and Wuxi market price? Please understand the information provided by users, thank you!

- Solid wood flooring speciesSolid wood floor due to the reorganization of the structure and other materials and composite processing, relatively high requirements for tree species, grades also by tree species. Generally speaking, the floor material is more than the hardwood, the grade is also higher, the coniferous material is few, the grade is also low. As a result of the implementation of the national natural forest protection project, the import of wood as raw material for solid wood flooring increased. As a solid wood flooring species can be divided into the following three categories:1, domestic hardwoodThis is a kind of widely used species, common are: beech, oak wood, rosewood, sandalwood, nanmu, beech, ash, oak, Quercus, yellow, red and white cone cone cone, red beech and Bai Qinggang, Huai wood, birch, red birch, elm, sassafras, Fenghua, Huang Qi, maple wood, neem wood, Schima superba, ash, red eucalyptus, Eucalyptus citriodora, walnut, hard Acacia, Catalpa wood, camphor wood, wood piles etc..

- Q: How to remove and dry out water stains from engineered ( not laminate , not true hardwood) wood floors?

- Let it air dry & sand with sandpaper.

- Q: Ask the difference between solid wood composite floor and diamond plate?

- In order to integrate the advantages of the above, and now has a solid wood composite floor. Solid wood flooring: from the plates of different species cross laminated solid wood flooring, overcomes the shortcomings of single sex, dry shrinkage and wet expansion rate is small, has good dimensional stability, and retains the natural tree wood floors and comfortable feeling. Wood flooring is divided into three layers of solid wood flooring, parquet parquet, model three, to solve the deformation defects do not wear the wood floors, and feel very comfortable, but also solve the old wood floor maintenance difficult disadvantage, represents the direction of development of the wooden floor.

Send your message to us

Yongsen Ecological Floor With High Quality

- Loading Port:

- Nanjing

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches