Electric Petrochemical Processing Pump Unit

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Electric Petrochemical Processing Pump Unit

Product Introduction and characteristics

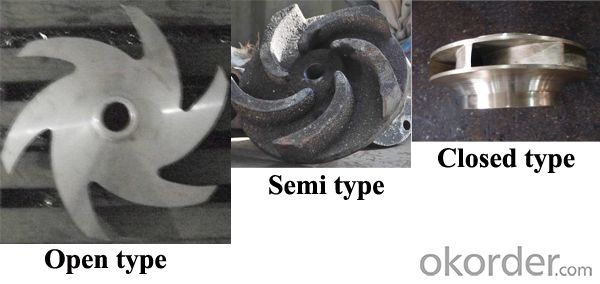

The G5 IH series end suction pump is a new generation of the traditional IH type pump. The two have the same performance and installation dimensions. It’s as per ISO24256,ISO2858,GB5662-85 Axial Suction Centrifugal Pump (16 bar)-Mark, performance and dimensions.

Based on the suspension appearance design of XA pump, the G5 IH pump is provided with strengthening ribs on its casin so that it’s characterized by its nice-looking appearance, safe and reliable operation and long service life.

Suspension part of G5 IH pump: four kinds of suspension, being universal, cover and cross the full line, thus ensuring a faster delivery and a smaller inventory.

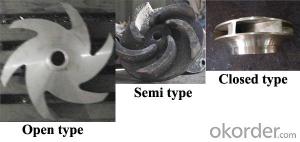

Shaft seal mode of G5 IH pump: including packing seal, single-end face unbalanced mechanical seal, single-end face balanced mechanical seal, double-end face unbalanced mechanical seal and double-end face balanced mechanical seal, as required by the customer. The seal is safe and reliable and has a long service life. The pump’s body and impeller adopt the precision casting with wax matrix, so it has a higher efficiency and a better appearance quality than the traditional IH.

The coupling is threesection and demountable. If a monoblock type is required, we can make special treatment to design the welding base separately. Generally the installation dimensions are the same as the traditional IH. The G5 IH series all adopts the precision base.

Main Application

It’s mainly used to transfer corrosive media containing no suspended particles or those unallowed to be polluted for industrial sectors like petrolem, chemical engineering, synthetic fiber, chemical fertilizer, power station, metallurgy, food and hospital.

Working conditions

Medium temperature: -20°C<T<+105°C

Up to 400°C when taking special measures:

Flow Q=3.4~2000m3/h,Head:3-200(m)

Rotation speed n=1450~3600 r/min,50Hz/60Hz

Pump’s rotation direction: clockwise when viewed from the motor to the pump.

- Q: We have a private well with a 40 year old water pump that is rusting away, and sounds like a truck. It's a double jet well pump sitting on a tank, with a second tank to one side that it's also connected to (with a thick pipe). I don't quite understand why there are two tanks (there's a third which is obviously the hot water). I'm guessing one of these is to hold water, and the other to provide air pressure? In any case, the pump runs OK, it doesn't leak, and provides plenty of pressure. It is just unbelievably loud. I've been told that replacing the bearings might take care of this problem, but seeing how the tank the pump rests upon (with a thin tube connecting it to the pump) is rotting away, and the system is older than I am, should I just replace the whole thing?

- It sounds like you have two pressure tanks. I am going to guess that the one under your pump probably went out and instead of taking it out and re-plumbing everything they just spliced in a new tank. You can get a re-build kit for most pumps but it sound like your pump is pretty old and probably being held together with faith and rust and taking it apart might cause more problems. What I would do is price out what the re-build cost and what labor might be against what a new system might be. If you decide to go with a new system I would suggest looking into getting a submersible pump, using the same tank but making sure it is in a good location and plumbed with a union. when your pressure tank finally goes out it is going to weigh a ton and trying to move it around plumbing can be difficult. good luck and happy holidays.

- Q: Hi I just brought a chrysler sebring V6 that needs a water pump. I found a water pump on OKorder for only $30 and it only had 900 miles and it works great. Should I buy it?

- Yes. Most salvage yards will give a 30 day warranty. It's worth a try. Make sure when you replace the water pump you also replace the timing belt. The reason is, in order to get to the water pump the parts all have to be removed so you might as well replace it when the mechanic is in there. Your timing belt could go out next week and you'd have to pay all of the labor again.

- Q: Not sure of the year model but think it is a 1991 to 1995 Jayco 2500FS bumper pull trailer. I bought it to put on a deer lease. One of the previous owners had taken out the water tank which I plan on replacing. I can't find the water pump to see if I need to replace it as well. Also, if you know about how the pump knows when to kick on i.e. pressure switch, push button or what. I know I could take it to have repairs done but enjoy the diy thing. I am in the process of finding out the exact year model as well. Thanks!

- having had many travel trailers the water pump is usually in a cabinet or under a bed or couch with a lot of plastic water lines near where you screw the water hose into the side of the trailer. and they are usually a preset psi from the factory so that is usually nothing to have to worry about and most have an on off switch located in the traier by the kitchen sink.And if the hot water heater is no good look into a tankless water heater it will save you money in the long run but initially you have to have a vent installed up through the roof away from a roof air vent. Another suggestion everytime you move a travel trailer they get the crap pounded out of them and someone needs to go up on the roof with a ladder and/or a plank that goes across the width so there is no weight standing on a roof to make dents or pop seams. Use some plastic stuff like plasticote available at wal mart after you move the trailer and set it up go up and make sure to double coat any of the seams that need it. I crank the heat up inside the trailer and do a double coat the heat rising will put a skin on the plasticote in a few hours instead of 12 or more. and the double coat gets any cracks missed the first time around. After that check it once a year if the trailer stays there.

- Q: my marine engine doesnt pump water can you tell me some faults can be thanks vic

- Depends on what engine and what pump check the impeller to see if it is bad.

- Q: Power went out of my house and we just had it restored, though now the water is no longer running. We called the people who installed our pump and they told us they would need to dig up the well which is going to cost $1500. However i remember a time before where this happened and all we needed to was reset the switch. Do you think these ppl are trying to get me for my money? Does anyone know if there is a less expensive way?

- the first thing to do is make sure your switch contacts are closed...if they are not and the switch has a handle on the side of it, lift up the handle until the contacts close....once the pump starts working and builds up 20 or 30 pounds pressure it will start working the way it is suppose to ...you would only need to dig up the well and pull the pump as a last resort...and since the pump was working before the power went out..Most likely all you need to do is figure out how to start it...if it is a jet pump (above ground pump) then all you might need to do is prime it to get it started again.....so your pump is a jet pump ?? how much water did they use to try to prime it with??it takes one gallon for every ten feet of pipe in the well.....if your pump is in the well it does not have to be primed...

- Q: i took off the water pump cover on my 1986 cr 250 and discovered that the impeller wont come off. ive tried turnig it the wrong way and the right way. can someone please tell me how to get it off.

- 1986 Cr 250

- Q: Fire hydrant and fire pump adapter difference

- Fire hydrant is out of water, the water pump is water supply to the pipe network

- Q: My dad wants to buy a salt water pump for a tiny pool.I'm not sure if it's pointless for the size that the pool is, but it is 12x12x3Is it too small of a pool or are there salt water pumps meant for tiny pools that I could look at?A link to any would be nice. :)Thanks!

- If you live the ocean try the shipyard, or any ,were around dock...or online..

- Q: About 2 months ago I started hearing a noise coming from my bathroom that sounded like loud humming every 3 or 4 seconds after I would turn on the water or flush the toilet. I noticed that when this noise happened the water pressure would increase and then it would go back to normal. Then the noise started to get louder. Last night while my husband was taking a shower the water lost pressure and then completely turned off. Now I have no water at all whatsoever except for maybe a few drops when I turn the faucet on. I have a private well and when I bought the house I was told that the well is underneath one of my bedrooms because the house was built on to and they built over the well. I know I can get to the pump from the crawl space. Has anyone had this problem or does anyone know what it might be or maybe even how much it could cost to fix?

- can you take pump apart an clean

- Q: Ok, I took my '93 Jeep Cherokee Sport 4.0L in to get the serpentine belt replaced, as the old one had snapped. They told me that the water pump had locked up and that's what made the belt break. The thing is, I had to get the radiator and water pump replaced this past summer and I am wondering what might've made my water pump lock up since it is new. The Jeep has a lot of miles and I'm slowly having to fix a lot of things, so I'm trying to be sure that I don't fix the pump just to find another problem. Also, the repair place told me the water pump looks brand new, so I know that it was definitely replaced, but should I contact the place the fixed the pump and radiator and see if there's some sort of warranty on the pump?

- I would check for the warranty for your water pump. I had an 89 GMC pickup and I kept blowing alternators and pulling front cover bolts that supported the power steering pump.. Your belt even snapped!?! Mine split. These are all symptoms of the serpentine belt being too tight. My automatic belt tensioner was at fault. Your water pump has probably got the belt around the pulley about 3/4 of the diameter. That equals a heavy load on the bearings resulting in them failing and locking up. Get yourselt a new belt tensioner this time.

Send your message to us

Electric Petrochemical Processing Pump Unit

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords