Customized Extruded Aluminum Profiles for Industrial Machinery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Industrial Aluminium Profiles For Machinery Description

Industrial Aluminium Profiles For Machinery is one semi-finished aluminium material. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel. Each profile is wrapped by the particular paper to avoid the scratching between each profile and also prevent the moisture in the air. Outside the bundle is fixed with the four wooden boards including support board vertically and base board on horizontal level. There are steel belts outside the boards to strap and tighten.

2. Specification of Industrial Aluminium Profiles For Machinery

Industrial Aluminium Profiles For Machinery | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Industrial Aluminium Profiles For Machinery

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Industrial Aluminium Profiles For Machinery

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Industrial Aluminium Profiles For Machinery

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

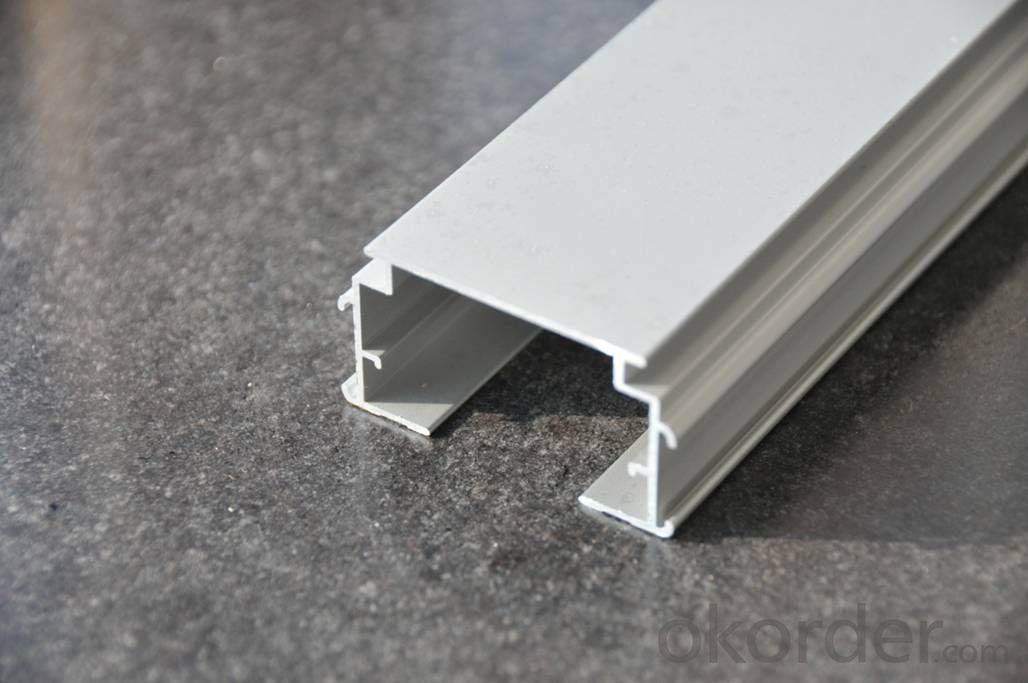

6. Image of Industrial Aluminium Profiles For Machinery

7. Package and shipping of Industrial Aluminium Profiles For Machinery

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum profiles be an alternative to steel or iron?

- Aluminum profiles offer a viable alternative to steel or iron in numerous applications due to their lightweight, durability, and exceptional resistance to corrosion. These qualities make them suitable for diverse industries like construction, automotive, aerospace, and electrical. Unlike steel or iron, aluminum exhibits a high strength-to-weight ratio, enabling it to provide equivalent strength while being significantly lighter. Consequently, aluminum profiles are easier to handle, transport, and install, resulting in reduced overall costs. Moreover, aluminum profiles can be easily extruded into intricate shapes, allowing for design flexibility and customization. Nevertheless, it is crucial to acknowledge that aluminum profiles might not be suitable for all applications requiring the high strength or hardness offered by steel or iron. Hence, the decision between aluminum, steel, or iron profiles will rely on the specific requirements of the project or product.

- Q: Can aluminum profiles be cut to size?

- Indeed, it is possible to cut aluminum profiles to fit specific dimensions. Typically, manufacturers produce aluminum profiles in standardized lengths, which can then be readily adjusted to the desired length or size through diverse cutting techniques such as sawing, shearing, or CNC machining. As a result, aluminum profiles offer personalized options and adaptability for a variety of applications.

- Q: Can aluminum profiles be used in signage or display applications?

- Yes, aluminum profiles can be used in signage or display applications. Aluminum profiles are versatile and lightweight, making them ideal for creating durable and visually appealing signs and displays. They can be easily cut, shaped, and joined together to create custom frames, panels, and structures for various signage and display purposes. Aluminum profiles also offer excellent corrosion resistance, ensuring that the signs or displays remain intact and attractive even in outdoor or high-moisture environments. Additionally, aluminum profiles can be powder coated or anodized to provide a wide range of color options, allowing for branding or customization. Overall, aluminum profiles offer a reliable and cost-effective solution for signage or display applications, providing both functionality and aesthetics.

- Q: What are the advantages of using aluminum profiles in the oil and gas industry?

- There are several advantages of using aluminum profiles in the oil and gas industry. Firstly, aluminum profiles are lightweight yet highly durable, making them ideal for applications that require strength and resistance to harsh environments. Secondly, aluminum profiles have excellent corrosion resistance properties, ensuring their longevity even in corrosive environments found in the oil and gas industry. Additionally, aluminum profiles offer excellent thermal conductivity, allowing for efficient heat transfer and management in various oil and gas processes. Furthermore, aluminum profiles are easy to fabricate and assemble, enabling quick and cost-effective installation. Lastly, aluminum is a recyclable material, aligning with sustainability goals and reducing environmental impact in the oil and gas industry.

- Q: How can I distinguish the aluminum profiles in the building and the aluminum in the industry?

- Door frames, aluminum profiles and doors and windows, aluminum profiles are in the building. Your picture is a line of scaffold material, usually in industrial material.

- Q: Aluminum 3100-6063-T5, please

- Aluminum in the industry according to material characteristics, such as hardness, strength, corrosion resistance and other categories, there are 8 main series, each series with 4 figures as a brand, and subdivided into many types1 series industrial pure aluminum: 1XXX2 series superhard aluminum material: 2XXX3 series easy cutting aluminum material: 3XXX4 series easy cutting aluminum material: 4XXX5 series magnesium aluminum alloy: 5XXX6 series anodic oxidation and corrosion resistant aluminum: 6XXX7 Series aviation ultra hard aluminum: 7XXX8 series: 8XXXYou say 3100-6063-T5 may contain the 3 and 6 series, easy to cut and resistant to corrosion,.T5 indicates hardness levels

- Q: Can aluminum profiles be used in exhibition booth and stand manufacturing?

- Yes, aluminum profiles can be used in exhibition booth and stand manufacturing. Aluminum profiles offer several advantages in this context. Firstly, they are lightweight, making them easy to transport and assemble at the exhibition venue. This also helps in reducing shipping costs. Secondly, aluminum profiles are highly durable and can withstand heavy usage. They are resistant to corrosion, ensuring that the exhibition booth or stand remains in good condition even after multiple uses. Additionally, aluminum profiles allow for easy customization and flexibility in design. They can be easily cut, shaped, and joined together to create various structures and configurations for the exhibition booth or stand. Furthermore, aluminum profiles can be powder-coated or anodized to provide a professional and visually appealing finish. Overall, aluminum profiles are a popular choice in exhibition booth and stand manufacturing due to their lightweight, durable, and customizable nature.

- Q: How do aluminum profiles perform in terms of creep resistance?

- Aluminum profiles generally have good creep resistance due to their high strength and stiffness. They can withstand sustained loads and high temperatures over a long period of time without significant deformation. However, the creep resistance of aluminum profiles may vary depending on the specific alloy and manufacturing process used.

- Q: What are the different extrusion processes used for aluminum profiles?

- There are several different extrusion processes used for aluminum profiles, including hot extrusion, cold extrusion, indirect extrusion, and direct extrusion. In hot extrusion, the aluminum is heated to a high temperature and forced through a die to create the desired profile. Cold extrusion involves forming the aluminum at room temperature using high pressure. Indirect extrusion involves pushing the aluminum billet through a stationary die, while direct extrusion involves pushing the billet through a moving die. Each process has its own advantages and is used for different applications in the manufacturing of aluminum profiles.

- Q: What are the advantages and disadvantages of the use of magnesium profiles compared with aluminum profiles?

- Note 1: the tensile strength of the magnesium alloy material made of the same volume of the frame strength than Aluminum Alloy, frame to achieve the strength to increase the thickness of the material and the tube, so from the perspective of the weight and Aluminum Alloy compared to magnesium alloy does not have any advantage.2 fatigue proof strength: the same volume of magnesium alloy material, the durability of the frame is worse than the aluminum alloy frame. It's also a fatal flaw for magnesium alloys. With the number of cycling more, the number of the stress is higher, intensity will be significantly reduced, even life is no more than 2-3 in the frame, so professional riders rarely use magnesium alloy frame, if used in the game, is calculated using the mileage to abandon the form of replacement.

Send your message to us

Customized Extruded Aluminum Profiles for Industrial Machinery

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords