corrugated stainless steel sheet with low price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot sale stainless steel sheet 201/202/304/304l/316/316l/430 in china alibaba

Product Description

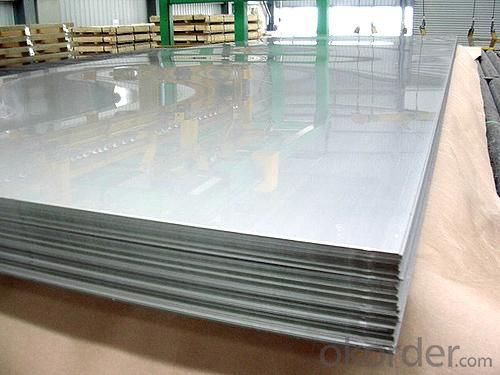

Stainless steel sheet Detailed introduction

Description | steel sheet,hot rolled steel sheet,cold rolled steel sheet, steel sheet,sheet,steel plate |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Application | Steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. |

Packaging | Standard export sea-worthy packing |

Delivery time | 10-30 days |

Quality | No.1 |

Productivity | 500 tons/Day |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Contacts | If you have any question,please feel free contact me. |

Stainless steel sheet surface finish characteristics

Surface finish | Characteristics and application |

2B | The surface brightness and flatness of no2B is better than no2D. then through a special surface treatment to improve its mechanical properties,No2B could nearly satisfy comprehensive uses. |

No.1 | Polished with abrasive belt of grit#100-#200, have better brightness with discontinuous coarse stria, used as inner and external ornaments for building, electrical appliances and kitchen utensils etc. |

No.4 | Polished with abrasive belt of grit #150-#180,have better brightness with discontinuous coarse stria, but thinner than No3, are used as bathtub buildings inner and external ornaments electrical appliances kitchen utensils and food processing equipment etc. |

HL | Polished with abrasive belt of grit #150-#320 on the NO.4 finish and has continuous streaks, mainly used as buildings ornaments elevators, door of building, frontal plate etc. |

BA | Cold rolled, bright annealed and skin-passed, the product have excellent brightness and good reflexivity like mirror, kitchen apparatus, ornament etc. |

8K | The product have excellent brightness and prefer reflexivity can to be the mirror. |

Application :

•Escalator, Elevator, Doors

•Furniture

•Production tools, Kitchen appliances, freezers, cold rooms

•Auto Parts

•Machinery and Packaging

•Equipment and Medical devices

•Transport system

Product Details:

Sandard Seaworth Packing(wooden packing with water proof paper)

If you have any question about stainless steel sheets,donot forget to sending the email to Us! You will get the competitive Price and have a very good experience about the Buying Process! CNBM International Corporation is always your trustful friend!

- Q: Are stainless steel sheets resistant to humidity?

- Stainless steel sheets possess resistance to humidity. The outstanding corrosion resistance properties of stainless steel are well-known, encompassing resistance to both moisture and humidity. This quality renders stainless steel sheets an appropriate material for a variety of applications in humid surroundings such as kitchens, bathrooms, and outdoor structures. The presence of chromium in stainless steel generates a protective layer of chromium oxide on the surface. This layer acts as a barrier against moisture, preventing its infiltration and subsequent corrosion. Moreover, stainless steel sheets find frequent use in industries such as food processing and pharmaceuticals, where cleanliness and hygiene are paramount. The sheets' resistance to humidity ensures their durability and longevity in such environments. All in all, stainless steel sheets serve as a dependable and long-lasting choice for humid conditions due to their innate moisture and corrosion resistance.

- Q: Can stainless steel sheets be used for elevator mirror panels?

- Yes, stainless steel sheets can be used for elevator mirror panels. Stainless steel is a durable and corrosion-resistant material that is commonly used in elevator design and construction. It is also highly reflective, making it an ideal choice for mirror panels. Stainless steel mirror panels not only provide a sleek and modern aesthetic to elevators but also offer excellent durability and ease of maintenance. Additionally, stainless steel can withstand the wear and tear of constant use, making it a reliable and long-lasting material for elevator mirror panels.

- Q: What is the fire rating of stainless steel sheets?

- The fire rating of stainless steel sheets is typically determined by their thickness and the specific grade of stainless steel used. Stainless steel has inherent fire-resistant properties, as it does not easily melt, ignite, or contribute to the spread of flames. However, the fire rating may vary depending on the application and the regulatory standards being followed. In general, stainless steel sheets are considered to have good fire resistance, but if a specific fire rating is required, it is recommended to consult with the manufacturer or a fire protection engineer for more accurate information.

- Q: Do stainless steel sheets require any special handling or storage?

- Yes, stainless steel sheets do require some special handling and storage to maintain their quality and prevent damage. Here are a few key points to consider: 1. Handling: When handling stainless steel sheets, it is important to wear gloves to avoid leaving fingerprints and oils on the surface, which can lead to corrosion. Additionally, sharp tools should be avoided while handling to prevent scratching the surface. 2. Cleaning: Prior to storage, stainless steel sheets should be thoroughly cleaned to remove any dirt, debris, or moisture. This helps to prevent the formation of rust or corrosion during storage. Mild soap or a specialized stainless steel cleaner can be used for cleaning. 3. Storage: Stainless steel sheets should be stored in a clean, dry, and well-ventilated area. They should be kept away from direct sunlight, extreme temperatures, and moisture, as these factors can lead to corrosion. Ideally, they should be stored in a covered area or wrapped in protective materials like plastic or cloth to prevent scratches and damage. 4. Separation: It is important to separate different sheets to avoid contact and potential scratching or damage. This can be achieved by using dividers or interleaf papers between the sheets. 5. Handling equipment: When moving or transporting stainless steel sheets, it is recommended to use appropriate handling equipment like forklifts or cranes. This ensures safe and secure movement without causing any dents or scratches. By following these handling and storage guidelines, stainless steel sheets can be effectively protected and maintained in optimal condition for their intended use.

- Q: How do I prevent discoloration on stainless steel sheets?

- To prevent discoloration on stainless steel sheets, it is important to regularly clean and maintain them. Use a soft cloth or sponge along with mild soap or a stainless steel cleaner to remove any dirt or grime. Avoid using abrasive cleaners or scrubbing pads, as they can scratch the surface. Additionally, be cautious of exposing stainless steel sheets to harsh chemicals or acidic substances, as they can cause discoloration.

- Q: Do stainless steel sheets require any special maintenance?

- Regular cleaning is necessary to keep stainless steel sheets looking good and preventing corrosion. Unlike other materials, stainless steel is resistant to staining, rust, and corrosion, so it requires less maintenance. However, it is important to clean stainless steel sheets regularly to get rid of dirt, debris, and fingerprints that can make them lose their shine. To clean stainless steel sheets, just use a soft cloth or sponge with mild soap and warm water. Avoid using abrasive cleaners or scrub brushes as they can damage the surface. After cleaning, make sure to dry the sheets thoroughly to avoid water spots or marks. By following these simple cleaning instructions, stainless steel sheets will remain beautiful and functional for many years.

- Q: Can stainless steel sheets be used for fire escapes?

- Yes, stainless steel sheets can be used for fire escapes. Stainless steel is known for its high strength, corrosion resistance, and durability, making it suitable for fire escape applications. It can withstand high temperatures and is not easily affected by fire or heat, ensuring the safety and reliability of fire escapes.

- Q: What is the maximum width of stainless steel sheets available?

- The maximum width of stainless steel sheets commonly available varies, but it typically ranges from 48 to 72 inches.

- Q: What are the common manufacturing standards for stainless steel sheets?

- The quality and consistency of stainless steel sheets are ensured by several common manufacturing standards. One widely recognized standard is the ASTM International standard, formerly known as the American Society for Testing and Materials. Specifically, the ASTM A240 standard specifies the chemical composition, mechanical properties, and other relevant characteristics of stainless steel sheets. Another important standard is the EN standard, specifically EN 10088, which provides guidelines for stainless steel flat products, including sheets. This standard covers dimensions, tolerances, surface finishes, and more. Different countries also have their own national standards. For example, in Japan, stainless steel sheets are classified under specifications such as JIS G4304 and JIS G4305, which are part of the Japanese Industrial Standards (JIS). These standards define the chemical composition, mechanical properties, and surface finishes of stainless steel sheets. In the United States, the American Iron and Steel Institute (AISI) sets standards for stainless steel sheets. The AISI 300 and 400 series are commonly used in manufacturing, and their properties are defined by the AISI. Manufacturers and suppliers must adhere to these standards to ensure that stainless steel sheets meet quality requirements and can be reliably used in various applications. These standards help maintain consistency, compatibility, and traceability in the production and use of stainless steel sheets across industries.

- Q: How do you prevent pitting corrosion on stainless steel sheets?

- To prevent pitting corrosion on stainless steel sheets, there are several measures that can be taken: 1. Proper alloy selection: Choosing the right grade of stainless steel with high resistance to corrosion is crucial. Grades such as 316 and 904L are known for their excellent resistance to pitting corrosion. 2. Passivation: Stainless steel sheets should be passivated after fabrication to remove any free iron or contaminants on the surface. Passivation involves treating the sheets with an acid solution, followed by a thorough rinse and drying. This helps to restore the protective chromium oxide layer on the surface, enhancing corrosion resistance. 3. Regular cleaning and maintenance: Stainless steel sheets should be cleaned regularly to remove any dirt, debris, or contaminants that can lead to pitting corrosion. Mild soap, water, and a soft cloth or sponge can be used for routine cleaning. Harsh or abrasive cleaners should be avoided. 4. Avoid exposure to aggressive environments: Stainless steel sheets should be protected from exposure to chemicals, chlorides, acids, and other corrosive substances. If such exposure is unavoidable, proper measures like the use of protective coatings or barriers should be implemented. 5. Avoid stagnant conditions: Pitting corrosion is often accelerated in stagnant or low-flow conditions where oxygen levels are depleted. Ensuring proper ventilation and circulation of air or fluids can help prevent pitting corrosion on stainless steel sheets. 6. Regular inspection and maintenance: Periodic visual inspection and monitoring of stainless steel sheets can help identify any early signs of pitting corrosion. If any pitting is noticed, immediate action should be taken to address the issue, such as applying a suitable corrosion inhibitor or protective coating. By following these preventive measures, it is possible to minimize the risk of pitting corrosion on stainless steel sheets, ensuring their long-term durability and performance.

Send your message to us

corrugated stainless steel sheet with low price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords