CORRIGATED SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 400 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

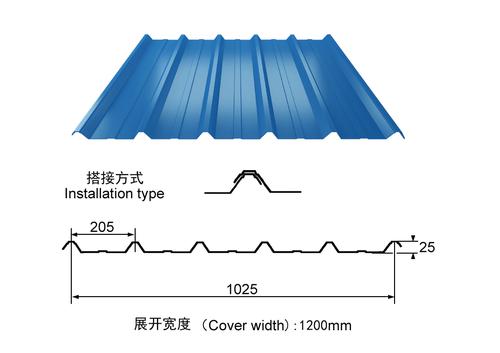

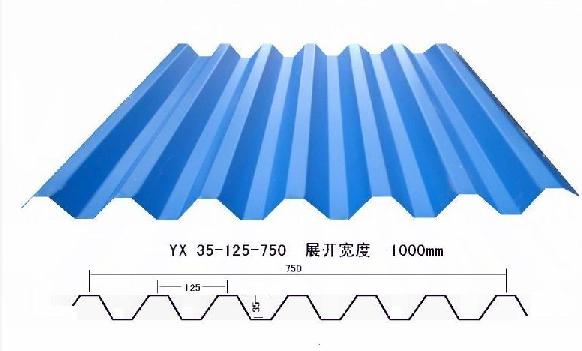

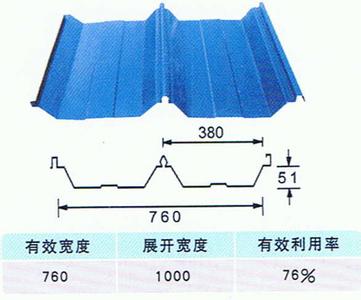

Product Name:corrugated steel roofing sheet

Effective Width:650mm to 1250mm

Thickness:0.13mm-0.8mm

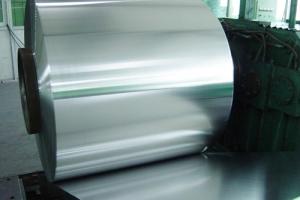

Material PPGI/PPGL steel coil

Coating:Z30-Z275,AZ30-AZ180

Color:white,blue or any RAL colors

length:1m-11.8m according to the container

top color coating:12um-25um

Back color coating:7um-10um

HRB:50-95

Base plate:PRE-PAINTED ALUZINC STEEL COIL,PRE-PAINTED GALVANIZED STEEL COIL

- Q: Can steel sheets be used for industrial shelving?

- Yes, steel sheets can be used for industrial shelving. Steel sheets are durable, strong, and resistant to corrosion, making them an excellent choice for heavy-duty industrial shelving applications. They provide stability and can withstand heavy loads, making them ideal for storing various industrial products and materials.

- Q: What is the weight of each steel sheet?

- The dimensions and thickness of each steel sheet determine its weight. Steel sheets are available in different sizes and thicknesses, resulting in varying weights. To calculate the weight, it is necessary to have the length, width, and thickness measurements of the steel sheet. Once these measurements are obtained, a weight calculator or a steel weight chart can be utilized to determine the weight per square meter or per square foot of the steel sheet. By multiplying this weight by the surface area of the sheet, the total weight of each steel sheet can be obtained.

- Q: Are steel sheets suitable for railway or transportation infrastructure?

- Yes, steel sheets are suitable for railway or transportation infrastructure. Steel is a durable and strong material that can withstand heavy loads and provide stability to railway tracks and transportation structures. It is commonly used in the construction of bridges, tunnels, and rail lines due to its high strength-to-weight ratio and resistance to corrosion. Additionally, steel sheets can be easily fabricated and installed, making them a practical choice for such infrastructure projects.

- Q: What's the difference between the three kinds of pickling plate, cold rolled plate and hot rolled plate?

- Hot rolled plate: that is, steel plate rolled at 800 degrees or so at high temperature

- Q: Are steel sheets suitable for building envelopes or curtain walls?

- Yes, steel sheets are suitable for building envelopes or curtain walls. Steel offers excellent strength and durability, making it a reliable choice for construction projects. It can withstand harsh weather conditions and provide a secure barrier against external elements. Additionally, steel sheets can be easily manipulated to create various architectural designs, allowing for flexibility and creativity in building envelope and curtain wall designs.

- Q: What is the maximum temperature that steel sheets can withstand?

- The maximum temperature that steel sheets can withstand depends on the specific grade of steel being used. However, most steel sheets can typically withstand temperatures up to 1,500 degrees Fahrenheit (815 degrees Celsius) without significant deformation or loss of strength.

- Q: What is the tensile strength of the steel sheets?

- The tensile strength of steel sheets can vary depending on the specific grade and thickness of the steel. Generally, steel sheets have a tensile strength ranging from 370 to 1,500 megapascals (MPa). However, it is important to note that different types of steel sheets have different tensile strength values. For example, low carbon steel sheets typically have a tensile strength of around 370 to 550 MPa, while high-strength low alloy (HSLA) steel sheets can have tensile strengths ranging from 450 to 1,200 MPa. Additionally, the thickness of the steel sheets can also affect their tensile strength, with thicker sheets generally having higher tensile strength values. Therefore, it is crucial to consult the specifications provided by the manufacturer or supplier of the steel sheets to determine the precise tensile strength for a particular grade and thickness.

- Q: Can steel sheets be used for decorative architectural elements?

- Yes, steel sheets can be used for decorative architectural elements. They offer a sleek and modern aesthetic, and their durability makes them suitable for both interior and exterior applications. Steel sheets can be customized with various finishes, textures, and patterns to add visual interest to architectural designs.

- Q: How do steel sheets compare to plastic sheets?

- Steel sheets are generally stronger, more durable, and have a higher heat resistance compared to plastic sheets. They are better suited for heavy-duty applications, such as construction and industrial uses, where strength and durability are crucial. Plastic sheets, on the other hand, are lightweight, flexible, and cost-effective. They are commonly used for applications where weight and cost are important factors, such as packaging, signage, and some consumer goods. Ultimately, the choice between steel and plastic sheets depends on the specific requirements and intended use of the sheets.

- Q: How do steel sheets perform under heavy loads or pressure?

- Steel sheets are renowned for their extraordinary strength and durability, rendering them highly impervious to immense loads or pressure. With their unique composition and manufacturing process, steel sheets possess an elevated tensile strength that empowers them to endure significant amounts of force without distorting or fracturing. This trait renders steel sheets exceptionally well-suited for applications involving substantial loads or pressure, such as construction, transportation, and industrial machinery. Moreover, steel sheets exhibit an exceptional load-bearing capacity, enabling them to evenly distribute applied pressure across their surface, thereby minimizing the likelihood of structural failure or damage. The rigidity of steel sheets further enhances their ability to withstand heavy loads or pressure, preventing them from bending or buckling and ensuring the integrity of the supported structure or equipment. In summary, steel sheets offer a dependable and robust solution for handling heavy loads or pressure, making them a favored material across various industries.

Send your message to us

CORRIGATED SHEET

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 400 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords