Stainless Steel sheet and Plate in Cheap price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of stainless steel

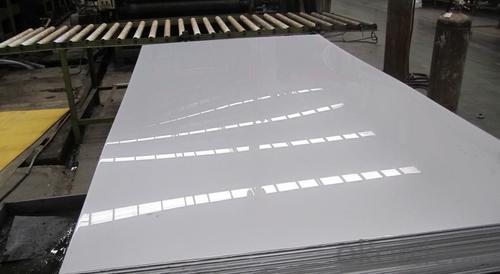

304 stainless Steel Plate

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

TISCO stainless Steel Plate 304/NO.1 finished

stainless steel plate,steel sheet,steel plate

Standard: ASTM,GB,DIN,JIS,ISO,EN,etc.

Delivery short and low cost advantage.

Description of stainless steel:

stainless steel plate,hot rolled stainless steel plate,cold rolled stainless steel plate,stainless steel sheet,steel sheet,sheet

Material of stainless steel:

304,304L,309S,310S,316,316L,316Ti,317L,317L,321,347H,409,409L,410S,420,430,201,202,etc.

Thickness of stainless steel:

From 0.3mm to 100mm

Width of stainless steel:

1000mm,1219mm,1250mm,1500mm,1800mm,2200mm,2500mm or as your requirement

Length of stainless steel:

2000mm,2438mm,2500mm,6000mm,6096mm or as your requirement

Application of stainless steel:

Stainless steel plate applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields. Our company has cooperative relation between the domestic agents. Stainless steel plate can be made accordingto the customers requirements. Fasten delivery. Quality assured.Welcome to order more.

Contacts

If you have any question,please feel free to contact us.

- Q: What are the different types of stainless steel sheet edges?

- Stainless steel sheets come in three main types of edges: mill edge, slit edge, and deburred edge. 1. The mill edge is the most common type and is produced during manufacturing. It has a rough, unfinished edge that is typically straight and perpendicular to the sheet's surface. It is suitable for applications where a smooth edge is not necessary. 2. Slit edge sheets are created by cutting large rolls of stainless steel into narrower widths. These edges are smoother and more precise compared to the mill edge. They are commonly used in applications that require a polished and precise edge, such as architectural finishes or fabrication processes. 3. A deburred edge is achieved by removing any sharp or rough edges from the stainless steel sheet. This is done to improve safety during handling or installation. Deburring can be done through grinding, sanding, or using specialized tools. The resulting edge is smooth and free from burrs or sharp protrusions. It's important to consider the specific application and requirements when choosing the edge type for a stainless steel sheet. Each type has its own advantages and limitations, and factors like aesthetics, functionality, and safety should be taken into account when selecting the appropriate edge for a project.

- Q: Can stainless steel sheets be used for backsplashes?

- Stainless steel sheets are indeed suitable for use as backsplashes. The reason why stainless steel is a popular option for this purpose is because it is durable, resistant to both heat and moisture, and requires minimal maintenance. Given that kitchen areas often experience high levels of heat and moisture, stainless steel is capable of withstanding these conditions, making it an ideal material for safeguarding walls behind stovetops and sinks. Moreover, stainless steel backsplashes can enhance the kitchen's appearance by providing a modern and sleek touch that complements various design styles. Additionally, cleaning stainless steel backsplashes is a breeze, as they can easily be wiped down using a damp cloth or cleaned with mild soap and water. All in all, stainless steel sheets are a practical and visually appealing choice for both residential and commercial backsplashes.

- Q: Can stainless steel sheets be used for wire mesh?

- Yes, stainless steel sheets can be used for wire mesh. Stainless steel is a versatile material that is commonly used in various applications due to its durability, corrosion resistance, and strength. When stainless steel sheets are processed into wire mesh, they can provide a strong and reliable mesh structure. Stainless steel wire mesh is often used in industries such as construction, agriculture, mining, and filtration, among others. It is known for its ability to withstand harsh environments, resist rust and corrosion, and maintain its structural integrity over time.

- Q: Can stainless steel sheets be painted or coated?

- Yes, stainless steel sheets can be painted or coated. However, it is important to properly prepare the surface by cleaning and applying a suitable primer before painting or coating to ensure adhesion and durability of the finish.

- Q: Are stainless steel sheets suitable for elevator control panels?

- Stainless steel sheets are indeed appropriate for elevator control panels. This resilient and impervious material is capable of enduring diverse environmental conditions, such as continuous usage, moisture, heat, and chemicals. Elevator control panels necessitate a substance that is effortless to cleanse, resistant to marks and deformations, and visually pleasing. Stainless steel fulfills all of these requirements, rendering it an optimal selection for elevator control panels. Moreover, stainless steel possesses a sleek and contemporary look, thereby augmenting the overall design of the elevator interior.

- Q: Can stainless steel sheets be used for elevator door frames?

- Indeed, elevator door frames can certainly utilize stainless steel sheets. Elevator door frames commonly opt for stainless steel as it possesses exceptional durability, resistance to corrosion, and captivating aesthetic charm. This material is capable of enduring the continuous opening and closing actions and is impervious to the numerous cleansing agents employed in elevator upkeep. Moreover, stainless steel imparts a polished and contemporary appearance that harmonizes splendidly with the elevator's overall layout. Furthermore, stainless steel proves to be effortlessly cleanable and maintainable, rendering it a pragmatic selection for elevator door frames.

- Q: What is the electrical resistivity of stainless steel sheets?

- The electrical resistivity of stainless steel sheets changes based on the particular grade or alloy composition of the stainless steel. In general, compared to materials like copper or aluminum, stainless steel has a relatively low electrical resistivity. The resistivity may vary from around 6.9 x 10^-7 ohm-meters (Ωm) for austenitic stainless steel to 7.2 x 10^-7 Ωm for ferritic stainless steel. It is worth mentioning that these values are approximate and can slightly differ due to factors like temperature and impurities in the stainless steel.

- Q: Are stainless steel sheets good for high-temperature applications?

- Yes, stainless steel sheets are excellent for high-temperature applications. Stainless steel has a high melting point, typically ranging from 1400 to 1450 degrees Celsius (2552 to 2642 degrees Fahrenheit), making it suitable for use in environments with elevated temperatures. Additionally, stainless steel exhibits excellent resistance to oxidation at high temperatures, which helps prevent the formation of scales or rust that can weaken the material. It also has good thermal conductivity, allowing for efficient heat transfer. These properties make stainless steel sheets a reliable choice for a wide range of high-temperature applications, including industrial furnaces, heat exchangers, boilers, and exhaust systems.

- Q: Can stainless steel sheets be used for architectural purposes?

- Yes, stainless steel sheets can be used for architectural purposes. This material is highly versatile and offers excellent durability, corrosion resistance, and aesthetic appeal, making it a popular choice for architectural applications such as facades, cladding, roofing, and decorative features. Stainless steel sheets can be shaped, formed, and finished to meet various design requirements, making them suitable for both functional and decorative architectural elements.

- Q: What are the different types of patterned finishes available for stainless steel sheets?

- There are several types of patterned finishes available for stainless steel sheets, including embossed, textured, perforated, brushed, and hammered finishes. Each of these finishes offers a unique aesthetic appeal and texture to the stainless steel, allowing for versatile applications in various industries such as architecture, interior design, and automotive.

Send your message to us

Stainless Steel sheet and Plate in Cheap price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords