Stainless Steel Sheet With Price In Different Grades

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

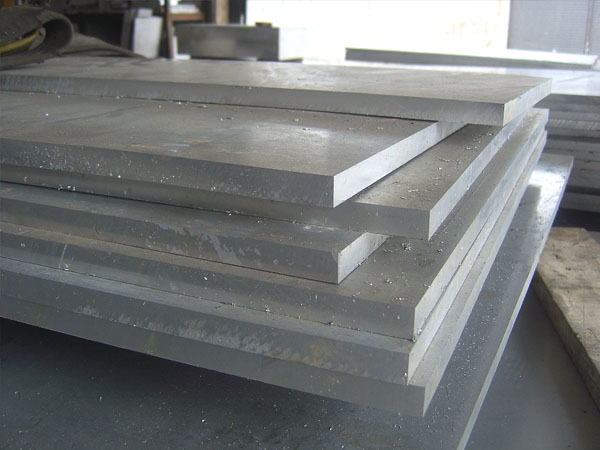

1.Structure of Product Description

There are many different grades, such as: 200 series, 300 series, 400 series, 900series, etc. The detailed grade are as follows: 201, 202, 301, 304, 316, 410, 420, 430, etc.

The surface is including 2B, BA, Mirror Finish, Checkered, etc.

2. Main features of the product

a. Competitive price

b. Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or else.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range?

---It is from 2000mm to 6000mm, etc.

What is the MOQ for your products yet?

Where is your client from?

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are stainless steel sheet, stainless steel coil, stainless steel checkered sheet, stainless steel mirror finished sheet, color coated stainless steel sheet, etc.

- Q: Are stainless steel sheets suitable for elevator handrails?

- Yes, stainless steel sheets are suitable for elevator handrails. Stainless steel is a popular choice for handrails in elevators due to its durability, corrosion resistance, and aesthetic appeal. Elevator handrails are subject to constant use and exposure to various environmental factors, such as moisture and fingerprints. Stainless steel is highly resistant to corrosion, ensuring the longevity and maintenance-free operation of the handrails. Additionally, stainless steel has a sleek and modern appearance that complements the overall design of elevators. Its smooth surface is easy to clean and maintain, making it a hygienic choice for handrails in public spaces. Overall, stainless steel sheets are an excellent material choice for elevator handrails.

- Q: 1cm thick 201 stainless steel plate how much money party

- 1 thick 201 stainless steel sheet, 95 yuan / square meters.Stainless steel (Stainless Steel) is stainless acid resistant steel abbreviation, resistant to air, steam

- Q: Can stainless steel sheets be used for water treatment equipment?

- Yes, stainless steel sheets can be used for water treatment equipment. Stainless steel is highly resistant to corrosion and oxidation, making it an ideal material for water treatment applications. It is commonly used for tanks, pipes, valves, and other components in water treatment systems. Stainless steel's durability and hygienic properties make it suitable for handling various types of water, including drinking water, wastewater, and industrial process water. Additionally, stainless steel is easy to clean and maintain, ensuring the longevity and efficiency of water treatment equipment.

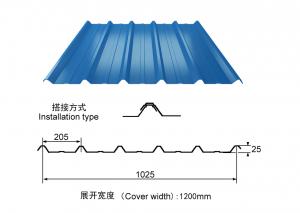

- Q: Can stainless steel sheets be used for roofing?

- Yes, stainless steel sheets can be used for roofing. Stainless steel is highly durable, corrosion-resistant, and can withstand extreme weather conditions, making it a suitable material for roofing applications.

- Q: Can stainless steel sheets be used for HVAC systems?

- Yes, stainless steel sheets can be used for HVAC (heating, ventilation, and air conditioning) systems. Stainless steel is a popular material choice for HVAC systems due to its excellent corrosion resistance, durability, and ability to withstand high temperatures. It is commonly used in HVAC applications such as ductwork, vents, and heat exchangers. Stainless steel sheets provide a smooth and clean surface, which helps in maintaining good air quality by preventing the build-up of dust, dirt, and other contaminants. Additionally, stainless steel is easy to clean and maintain, making it a suitable choice for HVAC systems that require regular maintenance and cleaning.

- Q: Can stainless steel sheets be used in marine environments?

- Yes, stainless steel sheets can be used in marine environments. Stainless steel is highly resistant to corrosion, making it suitable for marine applications where it will be exposed to saltwater and high humidity. It is commonly used in marine vessels, offshore platforms, and other structures that require durability and resistance to rust and corrosion.

- Q: Can stainless steel sheets be used for cryogenic applications?

- Yes, stainless steel sheets can be used for cryogenic applications. Stainless steel is known for its excellent mechanical properties, corrosion resistance, and low thermal conductivity, which make it suitable for cryogenic environments. It can withstand the extreme cold temperatures without becoming brittle or losing its strength. Stainless steel sheets are commonly used in cryogenic applications such as storage tanks, piping systems, and cryogenic equipment. However, it is important to choose the appropriate grade of stainless steel that is specifically designed for cryogenic applications to ensure optimal performance and durability.

- Q: What is the typical thickness range for stainless steel sheets?

- The typical thickness range for stainless steel sheets is between 0.4mm and 6mm.

- Q: What are the properties of stainless steel sheets?

- Stainless steel sheets are known for their corrosion resistance, high strength and durability. They have a smooth and shiny appearance, making them visually appealing. Additionally, stainless steel sheets are heat and fire resistant, making them suitable for various applications in industries such as construction, automotive, and food processing.

- Q: What are the common manufacturing standards for stainless steel sheets?

- There are several common manufacturing standards for stainless steel sheets that ensure their quality and consistency. One of the most widely recognized standards is the ASTM International (formerly known as the American Society for Testing and Materials) standard. ASTM A240 is the specific standard for stainless steel sheets, which specifies the requirements for chemical composition, mechanical properties, and other relevant characteristics of the material. Another important manufacturing standard is the EN (European Norm) standard, specifically EN 10088, which provides guidelines for stainless steel flat products, including sheets. This standard covers various aspects such as dimensions, tolerances, surface finishes, and more. Additionally, there are national standards developed by different countries. For example, in Japan, the Japanese Industrial Standards (JIS) classify stainless steel sheets under various specifications such as JIS G4304 and JIS G4305. These standards define the requirements for chemical composition, mechanical properties, and surface finishes of stainless steel sheets. In the United States, the American Iron and Steel Institute (AISI) also sets standards for stainless steel sheets. The AISI 300 and 400 series are commonly used in the manufacturing of stainless steel sheets, and their properties are defined by the AISI. It is important for manufacturers and suppliers to adhere to these standards to ensure that the stainless steel sheets meet the desired quality requirements and can be used reliably in various applications. These standards help maintain consistency, compatibility, and traceability in the production and use of stainless steel sheets across different industries.

Send your message to us

Stainless Steel Sheet With Price In Different Grades

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords