CORRIGATED SHEET

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

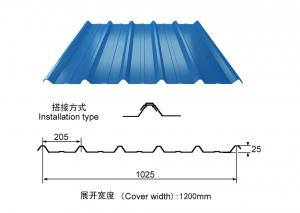

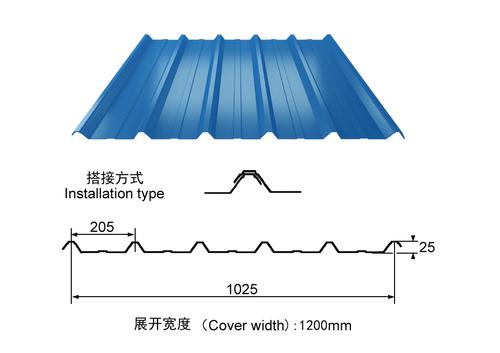

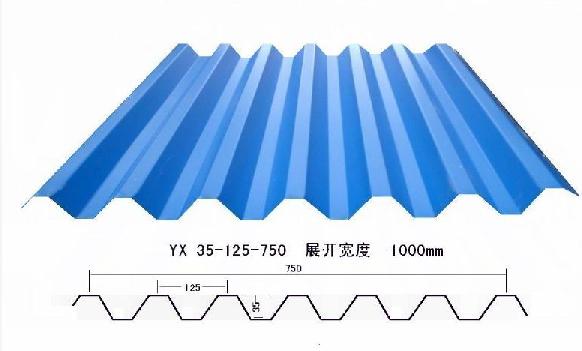

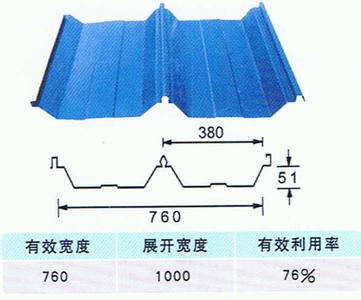

Product Name:corrugated steel

Effective Width:650mm to 1250mm

Thickness:0.13mm-0.8mm

Material PPGI/PPGL steel coil

Coating:Z30-Z275,AZ30-AZ180

Color:white,blue or any RAL colors

length:1m-11.8m according to the container

top color coating:12um-25um

Back color coating:7um-10um

HRB:50-95

Base plate:PRE-PAINTED ALUZINC STEEL COIL,PRE-PAINTED GALVANIZED STEEL COIL

- Q: What is the thickness range for steel sheets?

- The thickness range for steel sheets typically varies from 0.4 millimeters to 6 millimeters, depending on the specific application and industry requirements.

- Q: Can the steel sheets be bent or formed into different shapes?

- Yes, steel sheets can be bent or formed into different shapes. Steel is a highly malleable material, which means it can be easily manipulated and shaped without breaking. This allows for a wide range of applications where steel sheets need to be bent or formed into specific shapes, such as in the construction industry for manufacturing beams, columns, and other structural components. Various methods, such as cold forming, hot forming, and press braking, can be used to bend or form steel sheets into different shapes, depending on the desired end result and the thickness of the steel.

- Q: Can steel sheets be used for storage racks?

- Yes, steel sheets can be used for storage racks. They are durable, strong, and can safely support heavy loads, making them an ideal material for storage rack construction.

- Q: How are steel sheets protected during shipping?

- Steel sheets are typically protected during shipping by being wrapped in a layer of plastic or paper, and then secured with steel bands or straps to prevent movement and potential damage. Additionally, wooden or steel pallets are often used to provide a sturdy base and further protect the sheets during transit.

- Q: Can steel sheets be used for magnetic shielding?

- Yes, steel sheets can be used for magnetic shielding as they have high magnetic permeability, meaning they can redirect and absorb magnetic fields, providing effective shielding against magnetic interference.

- Q: Can steel sheets be painted or coated after installation?

- Yes, steel sheets can be painted or coated after installation. Painting or coating steel sheets after installation is a common practice to enhance their aesthetic appeal, protect them from corrosion, or provide specific functionalities such as fire resistance or insulation. The process involves proper surface preparation and choosing suitable paints or coatings that adhere well to the steel surface.

- Q: How can steel sheets be protected from corrosion?

- Steel sheets can be protected from corrosion through various methods such as applying protective coatings like paint or galvanization, implementing cathodic protection techniques, using corrosion inhibitors, or ensuring proper maintenance and regular inspection to identify and address any potential corrosion issues promptly.

- Q: What is the difference between a standard and high-strength steel sheet?

- The difference between a standard and high-strength steel sheet lies in their respective mechanical properties and performance characteristics. Standard steel sheets are often made from low to medium carbon steel, typically with a yield strength of around 250 MPa (megapascals). These sheets are commonly used in applications that do not require extreme strength or resistance to deformation. On the other hand, high-strength steel sheets are manufactured with a higher carbon content and alloying elements such as manganese, chromium, or nickel. This composition enables them to have significantly higher yield strengths, ranging from 350 to 1,000 MPa or even more. As a result, high-strength steel sheets offer enhanced resistance to deformation, higher tensile strength, and improved durability. Due to their superior mechanical properties, high-strength steel sheets are often selected for applications that demand increased strength-to-weight ratios, such as automotive components, structural parts, and heavy machinery. These sheets can withstand higher loads, endure extreme conditions, and provide better protection in case of impact or sudden forces. While standard steel sheets are more readily available and less expensive, high-strength steel sheets are preferred in situations where superior strength and performance are necessary. However, it is important to note that high-strength steel sheets may be more challenging to form, weld, or machine due to their increased hardness. Therefore, careful consideration of the specific application requirements is crucial when choosing between standard and high-strength steel sheets.

- Q: How do you store steel sheets to prevent damage?

- To prevent damage while storing steel sheets, it is important to keep them in a dry and well-ventilated area to avoid moisture buildup. Additionally, stacking them horizontally with proper support and using separators such as wooden pallets or rubber mats between each sheet can prevent scratches and dents. Regular inspection for any signs of corrosion or damage is also essential to address any issues promptly.

- Q: Can steel sheets be recycled after their useful life?

- Yes, steel sheets can be recycled after their useful life. Steel is one of the most recycled materials in the world, and steel sheets can be easily repurposed into new products through recycling processes. This helps conserve natural resources, reduce waste, and minimize environmental impact.

Send your message to us

CORRIGATED SHEET

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords