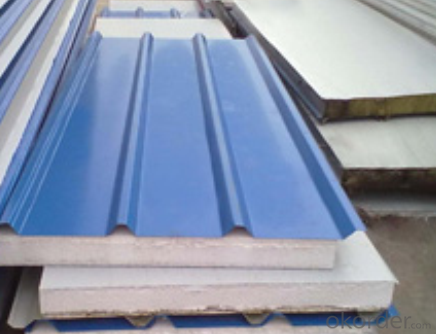

Color Corrugated coated Galvanized Steel sheet WithHot Selling Different Color

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Color Corrugated coated Galvanized Steel sheet With Different Color :

With Gi as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several Layers of color ,then after firing and cooling, finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding ,corrosion resistance

Main Features of Color Corrugated coated Galvanized Steel sheet With Different Color:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

2.Color Corrugated coated Galvanized Steel sheet With Different Color

3. Color Corrugated coated Galvanized Steel sheet With Different Color Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

4.Application for Color Corrugated coated Galvanized Steel sheet With Different Color

sandwich panel roofing, roofing structure, surface of sheet of balcony ,frame of window ,door, door of garage, roller shutter door, booth ,cabana, refrigerated wagon and so on indoor: frame of door, light steel structure of house, sliding door, folding screen ,ceiling ,internal decoration of elevator

5.FAQ of Color Corrugated coated Galvanized Steel sheet With Different Color

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.how long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. what is your moq

Normally our moq is 25per size ,but it is up to different size

- Q: Can the steel sheets be easily folded or creased?

- It is not possible to easily fold or crease steel sheets. Steel, being a robust and inflexible material, demands considerable force for bending or creasing. Its durability and resistance to deformation make it a popular choice in construction and manufacturing. Nevertheless, if the steel sheets are sufficiently thin, they might have enough malleability to be bent or creased by utilizing suitable tools and techniques.

- Q: What are the common thicknesses for stainless steel sheets?

- The common thicknesses for stainless steel sheets range from 0.4mm to 6.0mm, with the most commonly used thicknesses being 0.8mm, 1.0mm, 1.2mm, 1.5mm, and 2.0mm.

- Q: Are steel sheets suitable for HVAC systems?

- Yes, steel sheets are suitable for HVAC systems. Steel sheets are commonly used in HVAC systems due to their high strength, durability, and resistance to corrosion. They can be fabricated into various shapes and sizes to meet the specific requirements of HVAC components, such as ductwork, air handlers, and heat exchangers. Additionally, steel sheets can effectively withstand the high temperatures and pressures often encountered in HVAC applications.

- Q: What are the dimensions of standard steel sheets?

- The dimensions of standard steel sheets vary depending on the specific type and purpose. Generally, they come in rectangular shapes with typical dimensions ranging from 4 feet by 8 feet to 6 feet by 20 feet. However, it is important to note that custom sizes and shapes are also available to cater to different needs and requirements.

- Q: Can steel sheets be galvanized or coated with protective layers?

- Yes, steel sheets can be galvanized or coated with protective layers. Galvanization involves the application of a layer of zinc to the surface of the steel sheet, providing corrosion resistance. Additionally, steel sheets can be coated with various protective layers such as paint, powder coating, or epoxy to enhance their durability and protect against environmental factors.

- Q: What are the different grades of steel sheets?

- There are several different grades of steel sheets, which are classified based on their chemical composition, strength, and other properties. Some common grades include mild steel, stainless steel, high-strength low-alloy (HSLA) steel, and galvanized steel. Each grade has specific characteristics that make it suitable for different applications and industries.

- Q: What are the cost considerations for steel sheets?

- The cost considerations for steel sheets depend on various factors including the type and grade of steel, the size and thickness of the sheets, the quantity being purchased, and the current market conditions. Additionally, factors such as transportation costs, processing fees, and any additional customization or finishing requirements may also impact the overall cost of steel sheets.

- Q: What are the different sheet metal bending techniques for steel sheets?

- There are several sheet metal bending techniques for steel sheets, including air bending, bottoming, coining, and folding. Air bending involves applying force to the sheet metal to bend it using a V-shaped punch and a V-shaped die, without touching the bottom of the die. Bottoming involves bending the sheet metal until it comes into full contact with the bottom of the die, resulting in a tighter bend radius. Coining is a precision bending technique that uses a punch and a die to create a highly accurate and crisp bend. Folding, on the other hand, involves bending the sheet metal at a specific angle using a press brake or a folding machine. These techniques offer various options for achieving different bending requirements in steel sheet fabrication.

- Q: What is the process of embossing on steel sheets?

- Embossing on steel sheets involves the creation of raised or recessed designs on the surface. This technique is commonly used for texture enhancement, aesthetic improvement, or to enhance the mechanical properties of the steel. To begin the embossing process, the steel sheets are prepared. This involves cleaning the surface to remove any dirt, oils, or coatings that could interfere with the embossing. The sheets are then inspected for imperfections or defects that may impact the embossing quality. Once prepared, the steel sheets are placed in an embossing machine consisting of two or more rollers. These rollers have engraved patterns that will be transferred onto the steel sheets. They are typically made of hardened steel or other durable materials. As the steel sheets pass through the embossing machine, pressure is applied to the rollers, causing them to press against the steel surface. This creates a plastic deformation in the sheet, resulting in the desired raised or recessed pattern. The depth and intensity of the embossing can be adjusted by controlling the pressure applied by the rollers. In certain cases, heat may be used during the embossing process to soften the steel sheets, making them more malleable. This allows for deeper and more intricate embossing patterns. The temperature and duration of the heating process depend on the type of steel and desired outcome. After embossing, the steel sheets may undergo additional treatments such as cleaning, coating, or polishing to further enhance their appearance and protect them from corrosion. These finishing steps ensure that the embossed steel sheets meet quality standards and are ready for use. Overall, embossing on steel sheets is a versatile and effective method for adding texture and visual interest. It requires careful preparation, precise machinery, and skilled operators to achieve consistent and high-quality results.

- Q: Can steel sheets be perforated for ventilation purposes?

- Yes, steel sheets can be perforated for ventilation purposes. Perforated steel sheets are commonly used in various industries and applications where ventilation is required. The perforations in the steel sheets allow for the passage of air while still maintaining the structural integrity of the material. These perforations can be customized to meet specific ventilation requirements, such as the size and pattern of the holes. Perforated steel sheets are often used in HVAC systems, industrial equipment, architectural projects, and acoustic panels, among others, where a balance between ventilation and strength is necessary.

Send your message to us

Color Corrugated coated Galvanized Steel sheet WithHot Selling Different Color

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords