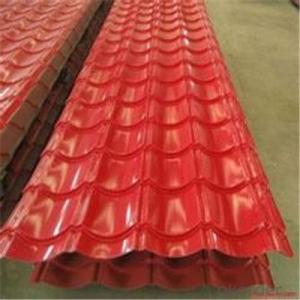

Prepainted Galvanized Corrugated Steel Plate Sheet:roofing sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard package for export |

| Delivery Detail: | 15 days after receipt the deposit or Original L/C |

Specifications

Prepainted roofing steel sheets

1. Thickness: 0.15mm---1.5mm

2. Width:800,900,1200,1220,1250mm

3.can be prepainted

Commodity | color coated galvanized steel plate |

Material | Galvanized steel sheet Galvalume steel sheet Pre-painted galvanized sheet |

Coating | PE,PVDF,galvanized(30-300g),galvalume (AZ80) |

Model No. | YX25-207-828 |

Sheet Thickness | 0.15---1.5mm |

Sheet Peak Height | 25mm |

Sheet Peak Spacing | 207mm |

Width | 800mm,900mm,1000mm |

Length | any length,according to the transportation,generally less than 12m |

Color | Standard color: red,blue,white grey Special color: according to RAL color |

Characteristic | 1 weatherproof 2 heating insulation 3 fireproof 4 anti-rust 5 sound insulation 6 long life span: more than 25 years

|

Packing | Plastic film,pallet or as your requests |

Delivery time | 15 days |

Payment | T/T,L/C |

Images:

- Q: What is the average cost of steel sheets per square foot?

- The average cost of steel sheets per square foot can vary widely depending on various factors such as the type of steel, thickness, size, and market conditions. However, as of 2021, the average cost of steel sheets ranges between $5 to $20 per square foot. It is important to note that this is a general estimate and prices may fluctuate based on location, supplier, and other market factors. Therefore, it is recommended to obtain quotes from multiple suppliers to get an accurate and up-to-date cost for steel sheets per square foot.

- Q: Can steel sheets be used for water tanks or storage containers?

- Yes, steel sheets can be used for water tanks or storage containers. Steel is a durable and strong material that can withstand the pressure and weight of holding water or storing various materials. It is commonly used in the construction of water tanks and storage containers due to its resistance to corrosion, ability to maintain structural integrity, and ease of maintenance. Steel sheets can be fabricated into different shapes and sizes to meet specific requirements, making them versatile for various applications. Additionally, steel is a recyclable material, which adds to its sustainability and environmental benefits.

- Q: What are the reasons for the steel mesh on both sides of the back pouring belt?

- 1, to solve the differential settlement of the high-rise building and the podium and set up the construction of the pouring belt is called the settlement post pouring belt.2, in order to prevent concrete condensation, shrinkage, cracking and set up after the construction zone is called "after pouring" belt.

- Q: Can steel sheets be used for kitchen or food preparation areas?

- Yes, steel sheets can be used for kitchen or food preparation areas. Steel is a durable and hygienic material that is resistant to corrosion, stains, and bacterial growth, making it suitable for food-related purposes.

- Q: Are steel sheets suitable for mining or construction equipment?

- Yes, steel sheets are highly suitable for mining or construction equipment due to their exceptional strength, durability, and resistance to wear and tear. Steel sheets can withstand heavy loads, harsh environments, and rough usage, making them an ideal choice for equipment used in these industries.

- Q: Can steel sheets be used for manufacturing industrial equipment?

- Yes, steel sheets can indeed be used for manufacturing industrial equipment. Steel is a versatile and widely-used material in various industries due to its strength, durability, and resistance to corrosion. Steel sheets can be easily molded, cut, and shaped into various components used in the manufacturing of industrial equipment such as machinery, tools, storage tanks, conveyors, and structural supports. Steel sheets also offer excellent load-bearing capacity, making them suitable for heavy-duty applications in industries like construction, automotive, aerospace, energy, and manufacturing. Additionally, steel sheets can be coated or treated to enhance their properties, such as improving resistance to heat, chemicals, or wear. Overall, steel sheets are a popular choice for manufacturing industrial equipment due to their strength, versatility, and reliability.

- Q: How do steel sheets perform in terms of corrosion resistance?

- Steel sheets generally have good corrosion resistance, especially when they are coated with protective layers such as zinc or alloys. The corrosion resistance of steel sheets depends on the composition and quality of the steel, as well as the environment in which they are utilized. Stainless steel sheets, for example, offer high resistance to corrosion due to the presence of chromium and other alloying elements. These sheets are particularly effective in environments with high humidity, saltwater exposure, or acidic conditions. However, uncoated or low-alloy steel sheets may be prone to rust and corrosion in aggressive environments. Regular maintenance, such as applying protective coatings or using corrosion inhibitors, can enhance the corrosion resistance of steel sheets and prolong their lifespan.

- Q: Are the steel sheets resistant to atmospheric corrosion?

- Yes, steel sheets are typically resistant to atmospheric corrosion due to their protective oxide layer which acts as a barrier against rust and other forms of corrosion caused by exposure to air and moisture.

- Q: What are the applications of steel sheets in construction?

- Steel sheets are widely used in construction for applications like roofing, flooring, wall cladding, and structural components due to their durability, strength, and versatility. They provide a reliable and long-lasting solution for various construction needs, ensuring stability, fire resistance, and protection against harsh weather conditions. Additionally, steel sheets can be easily customized, allowing for flexibility in design and construction processes.

- Q: Can the steel sheets be easily joined with adhesive?

- Yes, steel sheets can be easily joined with adhesive. Adhesive bonding is a commonly used method for joining steel sheets together as it offers numerous advantages. Adhesives provide a strong and durable bond between the sheets, allowing for a seamless connection. They also distribute stress evenly across the joint, reducing the likelihood of failure. In addition, adhesive bonding does not require heat or specialized equipment, making it a cost-effective and efficient solution. However, it is important to select the appropriate adhesive for the specific type of steel and surface preparation is crucial to ensure proper adhesion. Overall, when done correctly, adhesive bonding can effectively join steel sheets together.

Send your message to us

Prepainted Galvanized Corrugated Steel Plate Sheet:roofing sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords