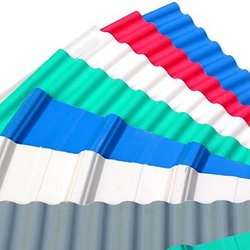

Prepainted Galvanised Corrugated Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

General Information Of Prepainted Galvanized Steel

With GI as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Thickness 0.23-1.2mm (BMT) |

Zinc Coating 80-275g/m2 |

Color According to RAL color fan |

Internal Diameter 508mm or 610mm |

Coil Weight 4-8MT |

Quality Commercial and structural quality |

Paint Polyester paint for topside, epoxy for reverse |

Standard JIS G 3312, ASTM A755M, EN 10169 |

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Prepainted Galvanized Steel

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Application Of Prepainted Galvanized Steel

Outdoor:

roof, roof structure, surface sheet of balcony, frame of window, door, door of garage, roller shutter door, booth, Persian blinds, cabana, etc.

In door:

door, isolater, frame of door, light steel structure of house, home electronic appliances, etc.

Packaging & Delivery Of Prepainted Galvanized Steel

Anti-damp paper inside full wrapped with plastic film, iron sheet outside on wooden pallet in 20 feet container with 25mt.

- Q: What are the common surface treatments for steel sheets?

- Common surface treatments for steel sheets include galvanizing, which involves applying a protective layer of zinc to prevent rusting; painting, which provides a decorative finish and additional corrosion resistance; and powder coating, which involves applying a dry powder to the surface and then curing it to create a durable, protective coating. Other treatments may include electroplating, chromating, or phosphating, depending on the specific requirements and intended use of the steel sheets.

- Q: What are the different thickness tolerances for steel sheets?

- The thickness tolerances for steel sheets can vary depending on the specific grade and type of steel being used. However, common thickness tolerances for steel sheets typically range from +/- 0.001 inches to +/- 0.030 inches, with tighter tolerances typically being required for more precise applications.

- Q: Q235 is hot rolled steel or cold rolled steel?

- Hot rolling and cold rolling are forming processes of profiled steel or sheet steel. They have a great influence on the microstructure and properties of steels. Steel is rolled mainly by hot rolling, and cold rolled only for the manufacture of small sections of steel and thin plates.The advantage of hot rolling is that it can destroy the casting structure of steel ingot, refine the grain of steel, and eliminate the defects of microstructure, so that the steel structure is compact and the mechanical properties are improved. This improvement is mainly reflected along the rolling direction, so that steel is no longer a certain extent, isotropic body; casting formed when bubbles, cracks and loose, can also be welded under high temperature and pressure.

- Q: What are the different storage methods for steel sheets?

- Steel sheets can be stored in various ways, depending on specific requirements and available space. Here are some commonly used storage methods: 1. For small quantities or lighter sheets, a basic method is flat storage, where sheets are placed horizontally on a flat surface like the floor or metal racks. 2. Vertical storage is another option, which involves placing sheets against a wall or using specially designed vertical racks. This not only saves floor space but also allows for easy access and identification of different sheet sizes. 3. To store long and heavy sheets, cantilever racks with horizontal arms extending from a vertical column provide excellent support. These racks facilitate easy loading and unloading using forklifts or cranes. 4. Roll-out racks, equipped with rollers or ball bearings, work like drawers, allowing steel sheets to be easily rolled in and out. This method is ideal when frequent access to different sheets is required, as it offers good visibility and convenient retrieval. 5. A-frame racks, featuring angled arms resembling the letter "A," are suitable for storing large quantities of steel sheets. This method provides easy access while ensuring organization. 6. For maximum storage capacity and efficiency, automated storage and retrieval systems (AS/RS) come into play. These computer-controlled systems can be designed as vertical lift modules or robotic systems, automatically storing and retrieving steel sheets. When choosing a storage method, it's crucial to consider factors such as sheet size, weight, accessibility, and safety. Additionally, adequate measures should be taken to protect the sheets from moisture, dust, and other environmental factors that could potentially impact their quality.

- Q: How are steel sheets protected during storage in outdoor environments?

- Steel sheets are protected during storage in outdoor environments through the application of various protective measures. These measures may include the use of weather-resistant coatings, such as galvanization or paint, to prevent corrosion and rusting. Additionally, steel sheets can be stored on pallets or racks to minimize contact with the ground and reduce the risk of moisture accumulation. Covering the sheets with tarpaulins or using weatherproof storage containers further shields them from direct exposure to rain, snow, and sunlight. Regular inspections and maintenance are crucial to ensure the effectiveness of these protective measures and to address any potential issues promptly.

- Q: What is the average cost of installing steel sheets?

- The average cost of installing steel sheets can vary depending on several factors such as the size and thickness of the sheets, the complexity of the installation, and the location. However, on average, the cost can range from $1,000 to $5,000 for a standard installation.

- Q: What are the different manufacturing processes for steel sheets?

- Steel sheets can be manufactured through various processes, each with its own unique characteristics and applications. Some commonly used methods include: 1. The most widely employed technique is hot rolling, which involves heating the steel billet or slab to a high temperature and passing it through rollers to reduce its thickness. As a result, the sheets have a smooth surface and excellent mechanical properties. 2. Cold rolling, on the other hand, rolls the steel at room temperature, yielding sheets with higher dimensional accuracy and surface finish. This process is often employed to produce sheets with tight tolerances and improved surface quality. 3. Galvanizing is a process where steel sheets are coated with a layer of zinc to prevent corrosion. The sheets are either immersed in molten zinc or electroplated with it, forming a protective barrier that extends the steel's lifespan. 4. Coating processes can also be applied to steel sheets to enhance their properties or appearance. For instance, powder coating involves electrostatically applying a dry powder that is then cured under heat. Paint coating, on the other hand, entails applying a liquid paint to the surface and allowing it to dry. 5. Pickling, a chemical process, is employed to remove impurities like rust, scale, and oxides from the surface of steel sheets. Typically, the sheets are immersed in an acid bath that dissolves these unwanted materials, leaving behind a clean surface. 6. Once the steel sheets are manufactured, they can undergo cutting and forming operations. Laser cutting, plasma cutting, or shearing can be utilized to shape the sheets into desired sizes and shapes. Additionally, the sheets can be formed into various products using techniques like bending, deep drawing, or roll forming. These examples highlight the different manufacturing processes for steel sheets, and the choice of method depends on factors such as desired sheet properties, surface finish, and intended application.

- Q: What is the reflectivity of steel sheets?

- The reflectivity of steel sheets varies depending on the surface finish and treatment, but generally, polished steel sheets have a high reflectivity, ranging from 60% to 95%.

- Q: Can the steel sheets be used for medical equipment?

- Indeed, medical equipment can make use of steel sheets. Steel's robustness, longevity, and resistance to corrosion render it a prevalent substance in the medical sector. It permits the production of an array of medical equipment, including surgical tools, hospital beds, medical trolleys, and diagnostic apparatus. Steel sheets can be conveniently shaped and crafted into diverse forms and dimensions, thereby catering to distinct requirements of medical equipment. Moreover, steel's hygienic attributes, facilitating easy sterilization, establish it as a fitting material for medical equipment necessitating regular sanitization.

- Q: Is 5mm thick steel plate tapping M8 thread reliable?

- The pitch of the M8 is 1.25, it can attack 4 teeth. The force of the thread is 4-5 teeth. The bottom is not greater than 6.7mm, 8.8 plus elastic pad bolt.

Send your message to us

Prepainted Galvanised Corrugated Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords