Corrugated Hot Dipped Galvanized Steel-Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Corrugated steel sheet is mostly used for architectural decoration. We have scores of corrugated sheets production lines of different types, producing profiled sheets of all kinds of types and colors. Since it adopts high strength steel sheet and the dimension is designed reasonably, the corrugated sheets are widely used on roofs and walls of various buildings, which can be easily installed, be flexible and changeable, unrestricted by no factor of the buildings. Pressing steel panel can be freely incised, it can satisfy the especially designing demands. It apply on convenient construction, and anti-seismic performance, fire proof, waterproof, .

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Application:

It has been widely applied on civil construction like storerooms, special building roof and walls of wide-span steel structure building and so on.

Pressing steel panel with the clear line, and many colors for choice, suitable for any different building style materials, achieving satisfy effects;

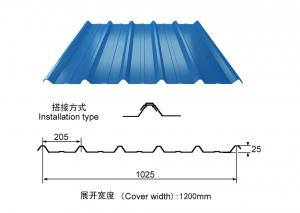

Product Specification:

Thickness tolerance: (+/-0.02mm)

Zinc coating: 40-180g/m2

Standard:jis g 3302, SGCH

Package: 2-3ton/pallet

Specs: 0.14-0.8mm x 900mm x 2000mm

Width:700-1250mm

Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Package:Standard seaworthy export packing

FAQ:

1. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

2.How many pieces for one package?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

3. Could you produce the sheets according to our design?

Yes, we can make it.

- Q: What are the different sizes of steel sheets available?

- Various sizes of steel sheets are readily available to cater to a range of applications and industries. The dimensions of steel sheets can vary depending on factors such as thickness, width, and length. In terms of thickness, steel sheets are commonly found in gauges ranging from 7 to 30. The gauge number indicates the thickness, with higher numbers representing thinner sheets. Thinner sheets, like those with a gauge of 30, are often used for flexible applications. On the other hand, thicker sheets, like those with a gauge of 7, are typically employed for heavy-duty applications that require strength and durability. When it comes to width, steel sheets are offered in a variety of choices. The most frequently seen widths include 36 inches, 48 inches, and 60 inches. Customized widths can also be obtained to meet specific requirements. Regarding length, standard lengths for steel sheets are typically 96 inches and 120 inches. These lengths are widely used in various industries. However, similar to width, length can also be customized to suit specific needs. It is important to note that the availability of different sizes of steel sheets may vary depending on the supplier and the specific grade of steel used. It is advisable to consult with a steel sheet supplier or manufacturer to determine the exact sizes available for a particular application.

- Q: What does "Z" mean to the performance of steel?

- The Z plate is used to prevent lamellar tearing of plates, the main connections at the plate, if the plates in the thickness direction bear significant tensile stress on the sheet.

- Q: Can the steel sheets be cut easily?

- With the correct tools and techniques, steel sheets can be easily cut. Despite its strength and durability, steel can still be cut through methods like shearing, sawing, or by utilizing plasma or laser cutting machines. The ease of cutting steel sheets is influenced by factors such as thickness and the particular type of steel employed. Generally, thinner sheets are more manageable to cut compared to thicker ones. Moreover, employing suitable cutting tools and adhering to safety precautions will guarantee a seamless and effective cutting process.

- Q: How do steel sheets perform in high-wind areas?

- Steel sheets perform well in high-wind areas due to their strength and durability. They have high tensile strength and can withstand the strong forces exerted by the wind, minimizing the risk of damage or structural failure. Additionally, steel sheets are resistant to warping and buckling, ensuring the integrity of the structure even under extreme wind conditions.

- Q: Are the steel sheets suitable for high-temperature applications?

- Yes, steel sheets are generally suitable for high-temperature applications. Steel is known for its excellent strength and durability, making it a popular choice for various industries requiring materials that can withstand high temperatures. Steel sheets can be manufactured to have high melting points and can retain their structural integrity even under extreme heat. Additionally, steel has good thermal conductivity, allowing it to efficiently transfer heat away from the surface. However, it is important to consider the specific grade and composition of the steel sheets as some alloys are specifically designed for high-temperature applications. It is recommended to consult with a materials engineer or specialist to ensure that the steel sheets selected are suitable for the specific high-temperature environment.

- Q: How do steel sheets differ from steel plates?

- Steel sheets differ from steel plates in terms of thickness. Steel sheets are generally thinner and have a thickness of up to 6mm, while steel plates are thicker and have a thickness exceeding 6mm. Additionally, steel sheets are often used for decorative purposes, whereas steel plates are used for structural applications that require greater strength and durability.

- Q: What is the difference between a brushed and etched steel sheet?

- A brushed steel sheet and an etched steel sheet are both types of metal sheets that have undergone different surface treatments, resulting in distinct appearances and characteristics. A brushed steel sheet is created by brushing the surface of the steel with an abrasive material, usually a wire brush or sandpaper. This process creates a textured pattern of fine lines or scratches on the surface of the steel. The purpose of brushing is primarily to enhance the aesthetic appeal of the steel sheet, giving it a satin-like finish. Brushed steel is often used in architectural and design applications where a sleek and contemporary look is desired. It is also commonly used in kitchen appliances and automotive parts due to its resistance to fingerprints and scratches. On the other hand, an etched steel sheet is produced by a chemical or acid etching process. This involves applying an acid-resistant material, such as a resist or a stencil, onto the steel surface and then exposing it to an acid solution. The acid eats away at the exposed parts of the steel, creating a pattern or design. Etching is used to achieve intricate and detailed designs on steel sheets, making it popular in industries such as signage, jewelry, and art. The etched patterns can range from simple geometric shapes to elaborate images or text. In summary, the main difference between a brushed and etched steel sheet lies in the method used to achieve their respective surface textures. Brushing results in a consistent pattern of fine lines, creating a satin-like finish for aesthetic purposes. Etching, on the other hand, involves a chemical process that creates detailed and intricate designs on the steel surface.

- Q: Are steel sheets suitable for data center infrastructure?

- Yes, steel sheets are suitable for data center infrastructure. Steel sheets are often used in the construction of data centers due to their strength, durability, and fire-resistant properties. They provide structural support for the infrastructure, including server racks, cabinets, and raised flooring systems. Steel sheets also help protect the data center equipment from potential hazards like electromagnetic interference (EMI) and physical damage. Additionally, steel sheets can be easily customized and configured to meet the specific requirements of a data center, making them a popular choice for infrastructure construction.

- Q: How do you store steel sheets to prevent damage?

- To prevent damage to steel sheets, it is important to store them in a dry and well-ventilated area to avoid moisture buildup. Sheets should be stored horizontally on a flat surface, ideally on pallets or racks, to prevent bending or warping. It is crucial to keep them away from direct contact with the ground or any other surfaces that could cause scratches or dents. Additionally, using separators or interleaving materials between each sheet can help prevent surface damage.

- Q: Are the steel sheets resistant to atmospheric corrosion?

- Generally, steel sheets possess resistance against atmospheric corrosion. However, the degree of resistance may differ depending on the specific steel type employed and the environmental conditions it encounters. For example, stainless steel sheets exhibit high resistance owing to the inclusion of chromium, which generates a safeguarding oxide layer on the surface. Conversely, carbon steel sheets might be more vulnerable to corrosion if they lack proper coating or treatment. Moreover, the presence of pollutants, humidity, and other atmospheric aspects can also impact the corrosion resistance of steel sheets. It is, therefore, crucial to take into account these factors and select the suitable steel type and protective measures to ensure enduring resistance against atmospheric corrosion.

Send your message to us

Corrugated Hot Dipped Galvanized Steel-Sheets

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords