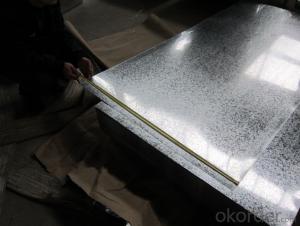

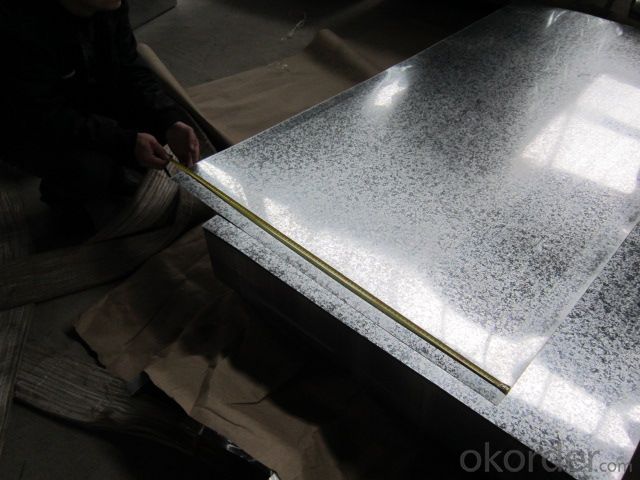

Hot-dipped Galvanized Steel Sheet in Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dipped Galvanized Steel Sheet in Sheet

Description:

The most external layer is all zinc, but successive layers are a mixture of zinc and iron, with an interior of pure steel. These multiple layers are responsible for the amazing property of the metal to withstand corrosion-inducing circumstances. Zinc also protects the steel by acting as a "sacrificial layer." If rust does take hold on the surface of Galvanized Steel Coil, the zinc will get corroded first. This allows the zinc that is spread over the breach or scratch to prevent rust from reaching the steel.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

Superiority:

1. Good Resistance to Corrosion

2. Qualified Processing Machinability

3. High Thermal Resistance

4. Excellent Reflectivity

5. Inexpensive and effective enough

6. Can be recycled and reused multiple times

Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Construction, packaging, railway vehicles, agricultural machinery and daily life.

Oiled/dry, Skin-pass/Nonskin-pass, Regular/Minimize/Zero Spangle

For countless outdoor, marine, or industrial applications, Galvanized Steel Coil is an essential fabrication component.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts.

Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

Product Specification:

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Zinc:40G-275G

Thickness:0.12mm-3.2mm

Width:600mm-1500mm

Length:1000mm-11800mm or as request

Package:Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one ton of the Steel Sheet?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. How many tons do you load in one 20’FCL?

Usually we can load 26tons in one 20’FCL container.

What is it Colored aluminum door? Have you seen it? Very much the type of door, sliding doors, folding doors, swing doors, etc., what type do you prefer? What classification Colored aluminum door?

Colored aluminum is the recent rise in the field of doors and windows, a new profile. In fact, almost Colored aluminum and aluminum, but the thickness Colored aluminum thick aluminum than the previous lot, and we had powder coating or electrophoresis. Colored aluminum alloy surface treatment of aluminum alloy performance is very stable and difficult to corrosion, usually surface after special treatment can be guaranteed for at least 30 years without fading LK.

Prospects of Colored aluminum

Surface oxidation-treated Colored aluminum display in the supermarket is very eye-catching. The above not only printed Logo, but also a perfect display of the characteristics of the product sold. Colored aluminum not only promote product sales, but also highlights the corporate image, use the display Colored aluminum is Value for money.

Colored aluminum door Category

1. Sliding doors: the appearance design is exquisite and elegant, exquisite and meticulous workmanship, surface profiles a variety of colors, and high intensity does not change color. Raster buckle through various styles and combinations of glass can be processed dozens of beautifully shaped door.

2. Hanging doors: In addition to having the characteristics of sliding doors, there is no threshold under the door inside and outside the ground into one, convenient for the elderly and children.

3. Folding: In addition to having a sliding door features, the door has a beautiful and sophisticated, open space is larger and so on.

4. Closet doors: In addition to having a sliding door features, compact design arc shape, thick wall sections, through a combination of different styles of doors and bar, can form a variety of styles closet doors.

5. Folding partition: The product is made of high quality accessories pulley folding, sliding folding lithe, while retaining the sliding door elegant appearance, easy to push, but its folding doors can push against both sides of the open space is larger. It is suitable for balconies and kitchens, etc. partition.

6. Cailv insulation were flat open: The window profiles are made of an insulating strip connecting the two sections together, using hollow glass, which is characterized by good sealing performance and energy saving, suitable for housing outside doors and windows can be used inside and outside of different colors aluminum, is currently building outside the window type commonly used.

- Q: Can the steel sheets be easily folded or creased?

- No, steel sheets cannot be easily folded or creased due to their strong and rigid nature.

- Q: What are the different types of steel sheet coatings available?

- There are several types of steel sheet coatings available, including galvanized, galvalume, tinplate, and stainless steel coatings. Each type offers different properties and advantages depending on the specific application and requirements. Galvanized coatings provide excellent corrosion resistance, galvalume coatings offer enhanced durability and heat reflectivity, tinplate coatings provide superior solderability and food-grade suitability, while stainless steel coatings offer exceptional resistance to corrosion, heat, and staining. The choice of coating depends on factors such as the environment, intended use, and desired performance of the steel sheet.

- Q: Are steel sheets suitable for HVAC systems?

- Certainly, HVAC systems can make use of steel sheets. Steel sheets are extensively employed in HVAC systems owing to their durability, strength, and corrosion resistance. They contribute to the structural integrity of the system and can endure high temperatures and pressure. Furthermore, steel sheets can be conveniently fabricated and tailored to meet specific requirements of the HVAC system. In addition, they are cost-efficient and have a prolonged lifespan, making them a favored option for components like ductwork, ventilation systems, and air handling units within HVAC systems.

- Q: Will the plating steel be rusty? Will it rust when touching the water?

- Galvanized steel plate as long as the plating is good, the surface coating does not fall off, will not rust, often see electroplating parts rust, because the coating is formed.

- Q: Can steel sheets be used in high-temperature environments?

- Yes, steel sheets can be used in high-temperature environments. Steel is known for its high strength and resistance to heat, making it a suitable material for applications that involve elevated temperatures. However, the specific type of steel and its composition should be considered to ensure it can withstand the desired temperature range without excessive deformation or deterioration.

- Q: What is the typical hardness range for steel sheets?

- The typical hardness range for steel sheets can vary depending on the specific type of steel and its intended application. However, a common hardness range for steel sheets is between 20 and 60 on the Rockwell C scale.

- Q: What is the typical price range for steel sheets?

- The price of steel sheets can fluctuate based on multiple factors, including the type and grade of steel, the thickness and size of the sheets, and the prevailing market conditions. Typically, the price range for steel sheets can vary from approximately $30 to $200 per sheet. Nevertheless, it is crucial to bear in mind that these figures are only approximate and can experience substantial fluctuations. To obtain the most precise and current pricing details for steel sheets, it is strongly advised to consult local suppliers or manufacturers.

- Q: How do steel sheets perform in abrasive environments?

- Steel sheets perform well in abrasive environments due to their high hardness and durability. They are able to resist wear and tear caused by abrasive particles, ensuring long-term performance and protection. The smooth surface of steel sheets also minimizes friction, reducing the chances of damage and maintaining their structural integrity even in harsh conditions.

- Q: Can steel sheets be used in oil and gas applications?

- Yes, steel sheets can be used in oil and gas applications. Steel is commonly used in the oil and gas industry due to its high strength, durability, and resistance to corrosion. Steel sheets are often used for constructing pipelines, storage tanks, and offshore platforms as they can withstand harsh operating conditions and provide long-term reliability.

- Q: Can steel sheets be bent or curved?

- Indeed, steel sheets possess the capability to undergo bending or curving. Steel, being a pliable substance, can be molded or shaped effortlessly without any risk of fracture or fissure. This particular characteristic enables steel sheets to be contorted or arched into diverse configurations and inclinations, contingent upon the sought-after result. The procedure of bending or curving steel sheets usually entails the utilization of specialized apparatuses, including press brakes or rollers. These instruments exert pressure on the steel sheet, compelling it to flex or curve in accordance with the desired specifications. The ability to manipulate steel sheets in this manner renders them exceedingly adaptable and extensively employed in industries such as construction, automotive, and manufacturing.

Send your message to us

Hot-dipped Galvanized Steel Sheet in Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords