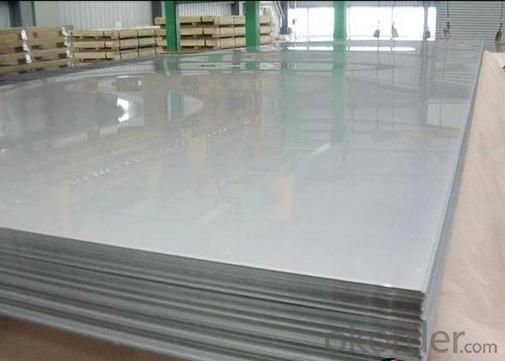

Best Quality for Cold Rolled Steel Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20Tons m.t.

- Supply Capability:

- 1000Tons Per Day m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Cold Rolled Steel Sheet

The raw material of cold rolled steel sheet is high quality hot rolled product, and after pickling, continuous rolling, degreasing, annealing, skin pass, slitting and cut to length line etc. Along with it many kinds of new technology and new process of global cold rolling production have been applied. Therefore the quality of the goods could be guaranteed. The finished product has a variety of excellent capabilities, such as processing capability and smooth, flat surface. It’s widely used in outdoor and interior decoration, furnishing manufacturing, home appliance, automobile etc.

Specifications of Cold Rolled Steel Sheet

1) Grade: SPCC, SPCD, SPCE, DC01-06, St12, Super deep drawing

2) Standard: JIS G3141-1996, EN 10131-2006, DIN EN 1002

3) Thickness: 0.20mm - 3.0mm

4) Width: 600/1000/1250/1500 (mm) or per customer's request

Package of Cold Rolled Steel Sheet

Strapped with min three strapping strips, covered by anti-water paper and plastic film, fixed on the iron or wooden pallets by strapping strips and covered by plastic bag to prevent damage from transportation.

Applications of Cold Rolled Steel Sheet

1) For the further producing of hot dip galvanized steel products

2) Cold rolled Steel: Auto manufacture, Oil drum, Transformer's tank panel, Furniture etc.

- Q: Can the steel sheets be easily formed into cylinders or tubes?

- Yes, steel sheets can be easily formed into cylinders or tubes. This process is commonly known as tube or pipe bending. Steel sheets, typically in the form of flat plates, can be bent using various methods such as roll bending, rotary draw bending, and induction bending. These techniques apply force to the steel sheet to gradually shape it into a cylindrical or tubular form. The flexibility and malleability of steel allow it to be easily molded into different shapes, including cylinders and tubes.

- Q: How do steel sheets perform in terms of weather resistance?

- Steel sheets possess exceptional weather resistance properties, renowned for their ability to withstand diverse weather conditions like rain, snow, and wind. This is attributed to their composition and the protective coatings they bear. Notably, steel sheets can endure extreme temperatures, both hot and cold, without experiencing any considerable deterioration or harm. Furthermore, their resistance to corrosion is highly pronounced, rendering them an optimal choice for outdoor applications and locations exposed to high humidity or saltwater. Consequently, the weather resistance possessed by steel sheets guarantees their long-lasting and robust nature, establishing them as a dependable option for a wide range of construction and industrial purposes.

- Q: What is the difference between a self-color and painted steel sheet?

- A self-color steel sheet refers to a sheet of steel that has not been coated or treated with any additional colors or finishes. It retains the natural color and appearance of the steel surface, which is typically a metallic gray or silver. On the other hand, a painted steel sheet is one that has been coated with a layer of paint or other protective finish. This coating serves multiple purposes, including enhancing the aesthetic appeal of the steel sheet, providing additional protection against rust and corrosion, and increasing the sheet's durability. The primary difference between a self-color and painted steel sheet lies in the presence or absence of a coating. While a self-color sheet maintains the raw and natural appearance of the steel, a painted sheet offers a wide range of color options, allowing for customization and harmonization with various design schemes. Additionally, the presence of a paint or protective coating on a steel sheet provides an extra layer of protection against environmental factors, such as moisture, chemicals, and UV rays. This helps prevent the steel from corroding or deteriorating over time, extending its lifespan and ensuring its performance in various applications. In summary, the main difference between a self-color and painted steel sheet is the presence or absence of a coating. While a self-color sheet retains the natural appearance of steel, a painted sheet offers added protection, customization options, and aesthetic appeal.

- Q: Are the steel sheets resistant to warping or twisting?

- Yes, steel sheets are highly resistant to warping or twisting. Steel is known for its exceptional strength and rigidity, making it less susceptible to deformation under stress or pressure. The inherent properties of steel, such as its high tensile strength and low thermal expansion, contribute to its resistance to warping or twisting. Additionally, steel sheets are often manufactured with precise dimensions and uniform thickness, further enhancing their resistance to deformation. This makes steel sheets a reliable and durable choice for various applications that require stability and structural integrity.

- Q: What are the most common thicknesses of steel sheets?

- Steel sheets come in various thicknesses, which are determined by their intended use and industry standards. Examples of commonly used thicknesses include 20 gauge (0.035 inches), 18 gauge (0.0478 inches), 16 gauge (0.0598 inches), 14 gauge (0.0747 inches), and 10 gauge (0.1046 inches). These thicknesses are commonly employed in sectors like construction, automotive, and manufacturing. In certain cases, thinner gauges like 24 gauge (0.0239 inches) and 22 gauge (0.0299 inches) may be utilized for lighter applications or when weight reduction is a priority. Ultimately, the chosen thickness will depend on the specific project requirements and the desired structural integrity.

- Q: Can steel sheets be recycled multiple times?

- Yes, steel sheets can be recycled multiple times. Steel is one of the most recycled materials in the world due to its durability and recyclability. When steel sheets reach the end of their useful life, they can be collected, melted down, and reprocessed into new steel products. This process can be repeated numerous times without compromising the quality of the steel. Recycling steel sheets not only conserves natural resources but also reduces energy consumption and greenhouse gas emissions associated with the production of new steel.

- Q: What factors affect the cost of steel sheets?

- Several factors affect the cost of steel sheets, including the current market demand and supply, raw material prices, manufacturing and processing costs, transportation and logistics expenses, as well as any applicable trade tariffs or taxes. Additionally, factors such as the type and quality of steel, size and thickness of the sheets, as well as any special finishes or coatings required, can also impact the overall cost.

- Q: How are steel sheets measured for thickness?

- Steel sheets are typically measured for thickness using a gauge or caliper, both of which provide precise measurements.

- Q: How do steel sheets compare to stainless steel sheets in terms of corrosion resistance?

- Stainless steel sheets have superior corrosion resistance compared to steel sheets, thanks to the presence of chromium that forms a protective layer against corrosion.

- Q: What is the difference between hot rolled and cold rolled steel sheets?

- The main difference between hot rolled and cold rolled steel sheets lies in the production process. Hot rolled steel sheets are manufactured at high temperatures, which results in a rougher surface and less precise dimensions. In contrast, cold rolled steel sheets are processed at lower temperatures and undergo additional rolling, resulting in a smoother surface finish and more accurate dimensions.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | China; Europe; America; Southeast Asia |

| Company Certifications | ISO9001、ISO14001、OHSAS18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Dalian |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 900,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | High; Average |

Send your message to us

Best Quality for Cold Rolled Steel Sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20Tons m.t.

- Supply Capability:

- 1000Tons Per Day m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords