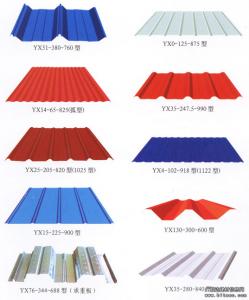

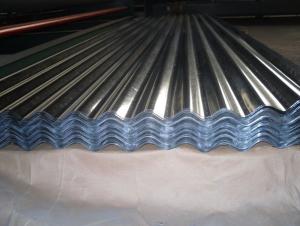

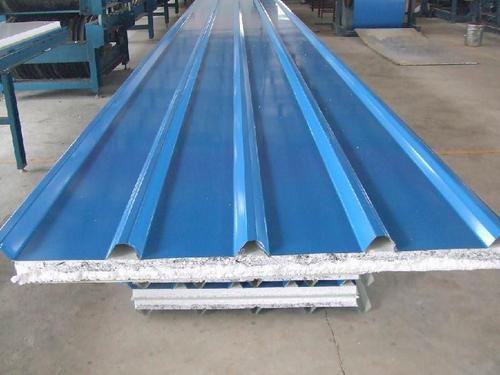

Corrugated steel sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Commodity | Hot dip galvanized steel coil and sheet |

Technical Standard: | JIS 3302 / ASTM A653 / EN10143 |

Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

Width | 500/650/726/820/914 |

Thickness | 0.12-2.8mm |

Type of coating: | Galvanized |

Zinc coating | Z30-275g/m2 |

Surface Treatment | Chromed / Skin-pass/ Oiled/Slightly Oiled/ Dry/ Anti-fingerprint |

Surface structure: | Zero spangle / minimized spangle / regular spangle/ big spangle |

ID coil | 508mm or 610mm |

Coil weight | 3-8 MT per coil |

Package: | Properly packed for ocean freight exportation in 20''containers |

Application: | Industrial panels, roofing and siding for painting |

Price terms | FOB,CFR,CIF |

Payment terms | T/T or L/C |

Delivery time | Within 30 days |

Remarks | Insurance is all risks |

MTC will be handed on with shipping documents | |

We accept the third party certification test,such as SGS/BV |

Technical data :

Hot dipped galvanized coil Technical Data

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

|

|

|

|

|

| |

Hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: How do steel sheets perform in terms of impact resistance?

- Steel sheets generally have excellent impact resistance due to their high strength and stiffness. They are capable of absorbing and distributing impact forces, making them highly resistant to deformation or cracking. Their ability to withstand impact makes them a popular choice for applications requiring protection against collisions or heavy loads.

- Q: What is the difference between a painted and laminated steel sheet?

- A painted steel sheet and a laminated steel sheet are both types of steel sheets that offer different characteristics and applications. A painted steel sheet is a steel sheet that has been coated with a layer of paint. This paint layer provides protection against corrosion and adds aesthetic appeal to the sheet. The paint can come in various colors and finishes, allowing for customization and versatility in design. Painted steel sheets are commonly used in architectural applications, such as roofing, siding, and wall cladding, as well as in automotive and appliance industries. The paint layer may require periodic maintenance to ensure its durability and appearance. On the other hand, a laminated steel sheet is created by bonding multiple layers of materials together. Typically, it consists of a steel core and one or more layers of other materials, such as plastic, polymer, or resin. The lamination process enhances the strength, durability, and performance of the steel sheet. Laminated steel sheets offer superior resistance against impact, scratching, and chemical exposure, making them suitable for applications that require high mechanical strength and protection, such as transportation, construction, and industrial equipment manufacturing. The laminate layers can also provide additional functionalities like sound insulation, thermal insulation, or fire resistance. In summary, the main difference between painted and laminated steel sheets lies in their composition and purpose. A painted steel sheet primarily focuses on aesthetics and corrosion protection, while a laminated steel sheet prioritizes strength, durability, and specialized functionalities. The choice between the two depends on the specific requirements of the application at hand.

- Q: Are steel sheets suitable for HVAC systems?

- Yes, steel sheets are suitable for HVAC systems. Steel sheets are commonly used in HVAC systems due to their high strength, durability, and resistance to corrosion. They can be fabricated into various shapes and sizes to meet the specific requirements of HVAC components, such as ductwork, air handlers, and heat exchangers. Additionally, steel sheets can effectively withstand the high temperatures and pressures often encountered in HVAC applications.

- Q: How do steel sheets perform in terms of vibration damping?

- Steel sheets have good vibration damping properties due to their high density and stiffness. They are effective in reducing vibrations and minimizing noise transmission, making them suitable for various applications requiring vibration control and noise reduction.

- Q: What is the difference between a smooth and diamond plate steel sheet?

- A smooth steel sheet refers to a sheet of steel that has a flat, even surface without any raised patterns or textures. It is typically manufactured through a process that involves rolling the steel and then smoothing it out to create a uniform appearance. Smooth steel sheets are often used in applications where aesthetics and a clean, polished look are desired, such as in architectural projects or for decorative purposes. On the other hand, a diamond plate steel sheet, also known as tread plate or checker plate, has a raised pattern of diamonds or lines embossed onto its surface. This pattern not only adds visual appeal but also provides enhanced traction and grip, making it ideal for applications that require slip resistance or protection against slipping hazards. Diamond plate steel sheets are commonly used in industrial settings, such as on ramps, stairs, or walkways, where there is a need for increased safety and stability. In terms of functionality, the main difference between a smooth and diamond plate steel sheet lies in their surface texture and the specific purposes they serve. While smooth steel sheets prioritize a sleek appearance, diamond plate steel sheets prioritize functionality and safety.

- Q: Are steel sheets suitable for playground equipment?

- Yes, steel sheets are suitable for playground equipment. Steel is a durable and strong material that can withstand heavy use and provide a safe environment for children to play. Steel sheets can be used to construct various playground equipment such as slides, climbing structures, and swing sets. Additionally, steel is resistant to weather conditions, making it a suitable choice for outdoor playgrounds. The material can be easily molded and shaped into different designs, allowing for creativity and customization in playground equipment. Overall, steel sheets are a reliable and long-lasting option for playground equipment, ensuring the safety and enjoyment of children.

- Q: Are steel sheets suitable for decorative screens or partitions?

- Indeed, decorative screens or partitions can be made using steel sheets. The versatility of steel as a material allows for a wide array of design possibilities. Intricate patterns and designs can be achieved through cutting, shaping, and welding steel. Furthermore, steel is known for its durability and long-lasting nature, making it suitable for both indoor and outdoor applications. To cater to different aesthetic preferences, steel can be painted or powder-coated in various colors. In addition to providing privacy, steel screens or partitions also enhance the visual appeal of a space. In summary, steel sheets offer immense potential for creating decorative screens or partitions due to their adaptability, resilience, and aesthetic capabilities.

- Q: Do steel sheets require any special storage or handling?

- Special storage and handling are required for steel sheets. To prevent corrosion and damage, it is crucial to store them in a dry and well-ventilated area, avoiding moisture buildup. Additionally, they should be kept away from direct sunlight and extreme temperature fluctuations to prevent warping or cracking. To prevent bending or sagging, steel sheets should be stored horizontally on a flat surface. Furthermore, it is advisable to stack them securely and appropriately, utilizing suitable supports or pallets, to prevent accidents or injuries. When handling steel sheets, proper lifting equipment and techniques should be employed to avoid injuries and sheet damage. Wearing gloves is essential to protect against sharp edges, and caution should be exercised to prevent contact with materials that may cause scratches or damage. Adhering to these storage and handling guidelines will ensure the durability and quality of steel sheets.

- Q: Are steel sheets prone to warping or buckling?

- Yes, steel sheets are prone to warping or buckling due to external factors such as heat, pressure, or improper handling.

- Q: Are the steel sheets easy to install?

- Indeed, the installation of steel sheets is generally a straightforward task. Their lightweight nature allows for easier handling and maneuverability throughout the installation procedure. Moreover, steel sheets often come equipped with pre-drilled holes or interlocking systems, which further streamlines the installation process. By employing the correct tools and possessing fundamental construction knowledge, individuals can effortlessly mount steel sheets onto diverse surfaces like roofs, walls, or fences. Nevertheless, it remains crucial to adhere to the manufacturer's instructions and safety guidelines to guarantee a correct and secure installation.

Send your message to us

Corrugated steel sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords