Construction Climb Mold Steel Formwork with high quality and competitive price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 5000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

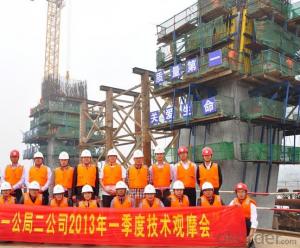

CNBM Climb Mold Steel Formwork

Product Introduction:

With the rapid development of urban rail transit project, the climb mold formwork is widely used in construction project. It have the advantages of noise-reduction good effect, low building height, high space utilization and good appearance.

With the progress of technology, construction method changes from cast-in-place to precast hoisting.

Specification:

Precast U-Beam formwork structure: outer side formwork, inner formwork, bottom formwork, support lead screw, JACK, work platform, Vibrator, crawling ladder, blanking plate etc.

Main products covers:

U-shaped beam

Segmental beam

Climb mold

Integrated pipe gallery

Automatic Prefabrication culvert

Shaped pier

T-beam

Alien template

Applied formwork Project:

Our products capacity:

More than 3 state grade certificates

More than 40 patents

More than 10 series main products

More than 10 government and project awards

WORKSHOP & EQUIPMENT:

Technology

We offer on site consultation and safety advice to help our customers work safely and improve productivity in each project.

CNBM combines its staff experience with advanced CAD systems and self-developed software to do this job to better meet the market requirements.

FAQ:

1. What we need for formwork design and make proposal?

Please offer the project drawing, CAD drawing for making design accurately.

2. How fast can the order be delivered?

Please kindly state your desired Delivery date for the order. The order and the desired delivery date will be checked after your order got sent. Of course, we will try our best to meet the specified delivery date.

3. What's the material of the products?

Steel Q235B or Q345B.

- Q: Remove the larger span of the beam pillar template why should be removed from the middle to the two ends

- Remove from the ends of beams began to load, is Liang Hezhu nodes under pure shear, a shear deformation from the middle split beam gradually remove support, after the load is gradually increased, the shear in the support under the protection of gradually increasing load, small impact.

- Q: Known length of 50.8 meters, known to be designed for the width of the area of the loss of 1 x 0.25, I have calculated the base cap,. {1.0 * 0.25 + [0.37 + 1 x 0.1 / 2 + 0.47 * 0.1] on the bottom and bottom formula is multiplied by the divided by two. So how to calculate the foundation beam. Formwork and cushion,

- Calculation of foundation beam! When the cap is to be deducted beam

- Q: When Liang Banzhong beam template calculation is the calculation of him in the board? Because in the calculation of engineering quantity of concrete beam by beam plate calculation. But when the template is, the book is not clear. In the calculation of the time quota template can have a beam plate.I use the Guizhou 04 quotaEspecially your last sentence, I haven't said anything yet,There is the Guizhou 04 fixed and did not say what sub beam frame beam separationAbove the beam plate is to explain the main beam, sub beam and plate, according to the calculation of beam and plate volumeThen you explain to me the frame beam is not the main beam? According to this explanation, why do you separate the frame beam

- There are beams and plates in the plate with a secondary beam, the frame beam can not be calculated, in the calculation, the plate and the secondary beam of the amount of work together, are the implementation of beam and plate

- Q: According to the experience, who knows the construction area and template, plate, column, beam volume, steel, etc.!

- Multi storey residential building structure of each floor area of square meters of content: the template to expand the area of about 2.4 to 2.9 square meters, concrete about 0.42 LiAbout 55 meters, reinforced to 65Kg.Basement floor area per square metre of content: the template to expand the area of about 2.4 to 3 square meters, concrete about 0.8 to 1.1 cubic meters,Steel bar about 125 to 170Kg.

- Q: Beam plate template is composed of the bottom template and what

- A, length, B width or height. Such as triangle F=0.5, A for the bottom edge of the length, B is high

- Q: Seeking beam, plate template engineering quantity

- Plate template (bottom area): (2.6*3- wall thickness) * (2.4*3- wall thickness) - (2.4*3- wall thickness) *0.2*2 [main beam] - (2.6*3- wall thickness) *0.25*2 [sub beam]

- Q: Beam plate with a few face template

- The beam of the beam plate is made up of 3 face plates, a bottom die and two side moulds

- Q: How to support 6m arc beam template how to set up?

- 6m beam if the horizontal direction of the arc beam, when the template is located at the end of the mold and the side of the mold is a patchwork way to support the mold, the arc is not small 500mm or 1000mm together, if the arc is large 300mm or 200mm together

- Q: A set of 50 m T beam steel template weight

- So this set of semi T beam template, the general weight is between more than and 60 tons to seventy tons. A little hope to adopt

- Q: What is the demolition order of the construction template

- Template removal sequence:General is the first non load bearing template, but bearing template; the first side plate, the back plate. Follow the line after the demolition, the demolition of non weight-bearing parts, the demolition of the load-bearing parts and the principle of top-down,

Send your message to us

Construction Climb Mold Steel Formwork with high quality and competitive price

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 watt

- Supply Capability:

- 5000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords