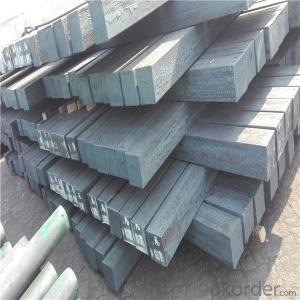

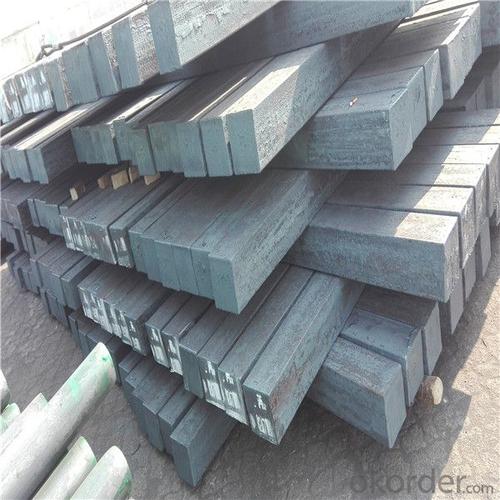

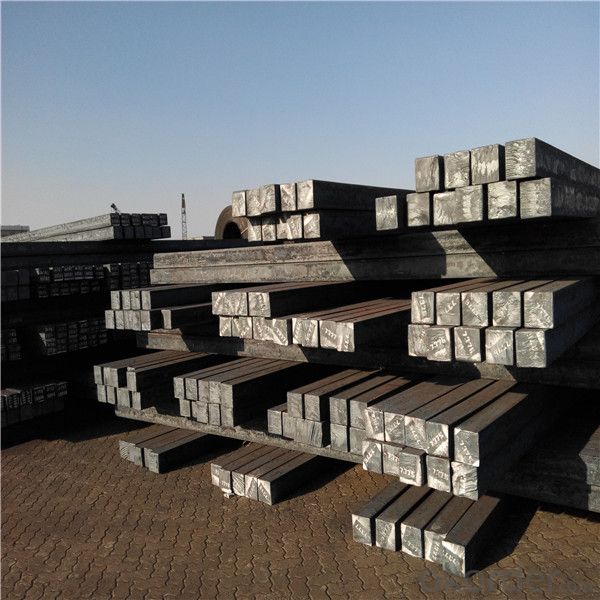

Square steel billets 150*150 from China market

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 31842 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building

the support foundation pile manufacturing.

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 45 days after receiving the L/C or advanced T/T payment.

Price term: FOB/CIF/ CFR according to clients requirements

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: How are steel billets used in the production of rebar?

- Steel billets are an essential raw material in the production of rebar. Rebar, also known as reinforcing bar, is a steel reinforcement used in concrete structures to provide strength and stability. The process of making rebar begins with the production of steel billets. Steel billets are solid, semi-finished steel products that are typically square or rectangular in shape. They are formed through the casting process, where molten steel is poured into molds and allowed to solidify. Once solidified, the billets are ready to be used in various applications, including the production of rebar. To produce rebar, the steel billets are first heated to a high temperature in a furnace. This process, known as hot rolling, softens the steel and makes it malleable. The heated billets are then passed through a series of rolling mills, where they are shaped into long, cylindrical rods with a specific diameter. During the rolling process, the steel billets are subjected to intense pressure and heat, which helps to align the grains of the steel and increase its strength. The rods are continuously rolled until they reach the desired dimensions and length. After the rolling process, the rods are cooled and cut into standard lengths to be sold as rebar. The resulting rebar is a strong and durable steel reinforcement that is widely used in construction projects. It is typically embedded in concrete structures, such as buildings, bridges, and highways, to enhance their load-bearing capacity and resist tension and bending forces. The use of rebar helps to prevent cracking and failure of concrete structures, ensuring their long-term durability and safety. In summary, steel billets are crucial in the production of rebar as they are transformed through the hot rolling process into long, cylindrical rods. These rods, once cooled and cut, serve as the essential reinforcement in concrete structures, providing strength and stability to the overall construction.

- Q: What is the role of steel billets in the construction of power plants?

- Steel billets are an essential component in the construction of power plants as they serve as the raw material for manufacturing various structural and mechanical components. These billets are used to fabricate beams, columns, plates, and other elements that provide strength and support to the power plant's infrastructure. They are also utilized in the production of machinery and equipment required for power generation and distribution. Overall, steel billets play a crucial role in ensuring the durability, stability, and safety of power plants.

- Q: What are the potential applications of steel billets in the medical sector?

- Steel billets have a wide range of potential applications in the medical sector. One of the key uses of steel billets is in the manufacturing of medical instruments and surgical tools. The high strength and durability of steel make it an ideal material for producing instruments that require precision and reliability. From scalpels and forceps to bone saws and orthopedic implants, steel billets can be transformed into various medical tools that are essential for surgeries and procedures. Additionally, steel billets can be utilized in the production of medical equipment such as hospital beds, wheelchairs, and stretchers. These products require a sturdy and robust material to ensure patient safety and comfort. Steel provides the necessary strength to support the weight of patients and withstand regular usage, making it an excellent choice for such applications. Furthermore, steel billets can be used in the construction of medical facilities and infrastructure. Steel is known for its structural integrity, making it suitable for building hospitals, clinics, and research laboratories. Steel structures offer resistance against earthquakes, fires, and other natural disasters, ensuring the safety of both medical personnel and patients. Moreover, steel billets can be employed in the manufacturing of medical storage systems and cabinets. These storage solutions are crucial for maintaining a sterile and organized environment, preventing cross-contamination, and ensuring the proper storage of medical supplies and equipment. In conclusion, steel billets have numerous potential applications in the medical sector. From the production of surgical instruments and medical equipment to the construction of medical facilities, steel's strength, durability, and reliability make it an invaluable material in enhancing patient care and safety.

- Q: How are steel billets used in the production of reinforcing bars?

- Steel billets are an essential component in the production of reinforcing bars. These billets, which are semi-finished steel products, serve as the raw material for the manufacturing process. To produce reinforcing bars, the steel billets are heated to a specific temperature in a furnace. This heating process helps to improve the malleability of the steel, making it easier to shape and manipulate. Once the billets have reached the desired temperature, they are then passed through a series of rolling mills. These mills apply significant pressure to the billets, gradually reducing their size and shaping them into the required dimensions for reinforcing bars. The rolling process also helps to improve the mechanical properties of the steel, enhancing its strength and durability. After the rolling process is complete, the now elongated steel bars are cut into specific lengths according to the desired dimensions and requirements. These lengths are then allowed to cool, which helps to stabilize the steel and prevent any deformations. Finally, the reinforcing bars undergo a surface treatment process, such as hot-dip galvanization or epoxy coating, to provide corrosion resistance and improve their longevity. This treatment further enhances the performance and lifespan of the reinforcing bars, making them suitable for use in construction projects. In summary, steel billets are used as the starting material in the production of reinforcing bars. Through a series of heating, rolling, cutting, and surface treatment processes, the billets are transformed into high-strength steel bars that provide reinforcement to concrete structures.

- Q: How are steel billets cut to size?

- Steel billets are typically cut to size using a variety of methods, depending on the specific requirements and the equipment available. One common method is by using saws or shears, which are capable of cutting through the steel with precision and accuracy. These tools can be operated manually or by using automated machinery. Another method is flame cutting, which involves using a high-temperature flame to melt and sever the steel. This technique is commonly used for thicker billets or when more intricate shapes are required. Similarly, plasma cutting is also a popular method for cutting steel billets. It utilizes a high-velocity jet of ionized gas, which is capable of melting and cutting through the steel. This method is often used when a high level of precision is required, as it offers smoother edges and a more precise cut. Additionally, water jet cutting is another option for cutting steel billets. This process involves using a high-pressure jet of water mixed with an abrasive material to cut through the steel. Water jet cutting is particularly suitable for materials that are sensitive to heat or for achieving intricate shapes. In some cases, steel billets may be cut using laser cutting technology. This method involves using a laser beam to heat and melt the steel, allowing for precise and efficient cutting. Laser cutting is often preferred for its ability to cut through various thicknesses and complex shapes. Ultimately, the choice of cutting method for steel billets depends on factors such as the desired precision, the thickness of the billet, the complexity of the shape, and the available equipment.

- Q: What are the properties of alloy steel billets?

- Alloy steel billets possess a combination of properties that make them highly desirable for various applications. These properties include high strength, excellent hardness and wear resistance, good toughness, and improved corrosion resistance compared to carbon steel. Additionally, alloy steel billets have the ability to withstand high temperatures and exhibit excellent machinability, making them ideal for use in industries such as automotive, aerospace, construction, and manufacturing.

- Q: How are steel billets used in the production of automotive frames?

- Steel billets serve as the primary raw material in the production of automotive frames. These billets, which are essentially long, rectangular-shaped pieces of steel, undergo heating and subsequent shaping using diverse manufacturing processes. Specifically, in the case of automotive frames, billets are heated and then passed through a series of dies and rollers to attain the desired shape and dimensions. Once the billets have taken on the appropriate form, they undergo further processing through cutting, bending, and welding techniques. These techniques are employed to create the intricate and robust structure characteristic of automotive frames. The preference for steel billets in automotive frame production stems from the material's exceptional strength and durability, critical factors in ensuring vehicle safety and structural integrity. Furthermore, steel billets offer exceptional formability and machinability. This enables manufacturers to craft complex frame designs that meet the specific requirements of different vehicle models. Additionally, steel is a cost-effective material, making it a favored choice for mass production within the automotive industry. In conclusion, steel billets play a crucial role in the production of automotive frames. They provide a robust and dependable foundation for the vehicle's structure. Combined with advanced manufacturing techniques, the utilization of these raw materials ensures that automotive frames can withstand a variety of forces and impacts, ultimately enhancing the overall safety and performance of vehicles.

- Q: What are the different types of defects in steel billets?

- There are several types of defects that can occur in steel billets, including surface defects such as cracks, scabs, and laps, as well as internal defects like inclusions, segregation, and shrinkage cavities. These defects can affect the quality and performance of the steel and may require remedial measures or rejection of the billets.

- Q: How are steel billets used in the manufacturing of automotive components?

- Steel billets are an essential raw material used in the manufacturing of automotive components. These billets are semi-finished products that are shaped into various forms to create the necessary components. Firstly, steel billets are heated to a specific temperature to make them malleable and easier to work with. Once they reach the desired temperature, they are placed into a mold or die and subjected to intense pressure to shape them into the desired form. This process is known as forging. Automotive components such as engine parts, gears, axles, and suspension components require high strength and durability. Steel billets are preferred for these applications due to their excellent mechanical properties, including high tensile strength, toughness, and wear resistance. After the forging process, the shaped billets are further processed through various techniques such as machining, heat treatment, and surface finishing to achieve the final specifications required by automotive manufacturers. These processes ensure that the components meet the necessary performance standards, dimensional accuracy, and surface quality. The use of steel billets in the manufacturing of automotive components offers several advantages. Steel is readily available, cost-effective, and has a high recycling rate, making it an environmentally friendly choice. Additionally, steel's versatility allows for a wide range of component designs and customization options to meet specific automotive requirements. In conclusion, steel billets play a crucial role in the manufacturing of automotive components. Their malleability and excellent mechanical properties make them an ideal raw material for forging processes, enabling the production of high-strength and durable components used in various automotive applications.

- Q: How do steel billets contribute to the overall seismic resistance of a structure?

- The overall seismic resistance of a structure is greatly improved by the presence of steel billets. When incorporated into concrete structures, steel billets act as reinforcement, boosting the structure's strength and longevity. This reinforcement enables the structure to better endure the forces and vibrations unleashed by earthquakes. The impressive tensile strength of steel billets enables them to efficiently absorb and distribute seismic energy, significantly decreasing the likelihood of structural failure during an earthquake. Moreover, steel billets have the capacity to be transformed into specialized structural elements, such as braces or shear walls, which are strategically positioned within the structure to counteract the lateral forces resulting from earthquakes. By utilizing steel billets, these structural elements are able to effectively absorb and disperse the seismic energy, successfully safeguarding the overall structure from substantial harm. Furthermore, steel billets are instrumental in the construction of seismic dampers, which are devices created to soak up and dissipate the energy generated by seismic events. When steel billet-based dampers are installed, the structure is able to significantly diminish the transfer of seismic energy to the building, thereby minimizing the potential for damage. Additionally, steel billets possess outstanding ductility, which is the capacity to deform without breaking. During an earthquake, structures experience considerable movement and vibrations. The ductile nature of steel allows it to flex and bend under these forces, proficiently absorbing seismic energy and preventing sudden, catastrophic failure of the structure. In conclusion, steel billets enhance the overall seismic resistance of a structure by providing additional strength and durability, facilitating the creation of specialized structural elements, enabling the construction of seismic dampers, and offering exceptional ductility. Their application elevates the structure's ability to withstand seismic forces, reducing the risk of damage and ensuring the safety of its occupants.

Send your message to us

Square steel billets 150*150 from China market

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 31842 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords