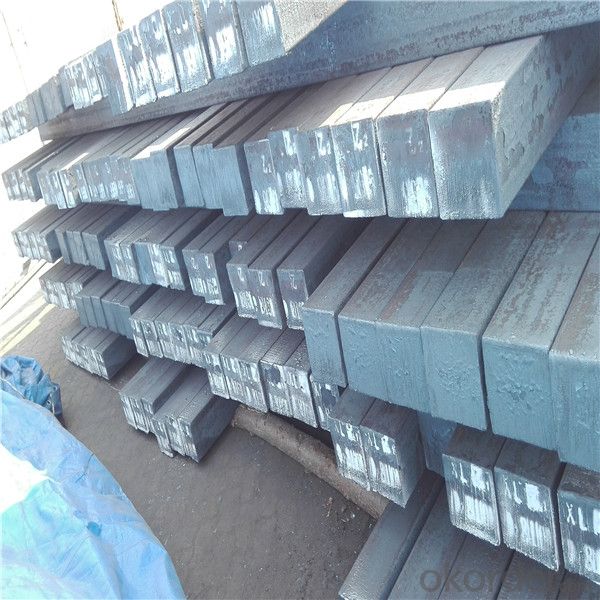

Alloy steel billet square prime from china

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 31264 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel billet

Steel billets have distinct characteristics as compared with already furnished steel bars and products.

Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel

billets are also known for their malleability and ductility, especially when exposed to varying temperatures

during shaping and molding.

Qaulity:own factory, stable quality

Tolerance: Strictly according to the G/B and JIS standard

Delivery time: within 45 days after receiving the L/C or advanced T/T payment.

Price term: FOB/CIF/ CFR according to clients requirements

Payment terms: 100%Irrevercable L/C at sight or T/T

Gade:

Standard | C(%) | Mn(%) | S(%) | P(%) | Si(%) |

Q195 | ≤0.12 | ≤0.50 | ≤0.040 | ≤0.035 | ≤0.30 |

Q235 | ≤0.20 | ≤1.40 | ≤0.045 | ≤0.045 | ≤0.35 |

Q275 | ≤0.22 | ≤1.50 | ≤0.045 | ≤0.045 | ≤0.35 |

20MnSi | 0.17-0.25 | 1.2-1.6 | ≤ 0.050 | ≤ 0.050 | 0.40-0.80 |

3SP | 0.14-0.22 | 0.40-0.85 | ≤ 0.050 | ≤ 0.040 | 0.05-0.15 |

5SP | 0.28-0.37 | 0.50-1.00 | ≤ 0.050 | ≤ 0.040 | 0.15-0.30 |

Our service :

We have a plant and professional team to provide our best service, from the start of production until the

loading into the vessel, we have a complete quality follow up procedure, to assure our products arrives to the customer with satisfaction. Welcome new and old customers

to contact us for future business relationships! We will give you a surpise price.

Packing :

Within 30 days

1.Standard export package

2.In bundles with steel strips

3.As the requirements of the customers

FAQ:

Q: What is payment terms?

A: FOB 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T BEFORE SHIPMENT

CIF and CFR 30% T/T IN ADVANCE AS DEPOSIT AND 70% T/T AS THE COPY OF B/L OR L/C AT SIGHT

Q:How to guarantee the quality of the products?

A:We have established the international advanced quality management system,every link from raw material

to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market.

At the same time, we will provide necessary follow-up service assurance.

Q:How long can we receive the product after purchase?

A :In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

The pecific time of receiving is related to the state and position of customers.

- Q: What are the different types of steel billet handling equipment?

- There are several different types of steel billet handling equipment used in various stages of the steel production process. These equipment are designed to efficiently move and transport steel billets, which are semi-finished metal products used for further processing. 1. Overhead Cranes: Overhead cranes are commonly used in steel mills and foundries for the handling and transportation of steel billets. These cranes have a high lifting capacity and can move billets from one location to another within the facility. 2. Mobile Cranes: Mobile cranes are versatile and can be used for handling steel billets in both indoor and outdoor environments. They are equipped with hydraulic systems for lifting and maneuvering heavy loads. 3. Forklifts: Forklifts are commonly used in warehouses and storage facilities to handle steel billets. They have forks at the front that can be raised and lowered to lift and move the billets. 4. Grab Buckets: Grab buckets are used for handling bulk materials, including steel billets. They have a bucket-like structure that can be opened and closed to grab and release the billets. These are often used in ports and shipping yards for loading and unloading billets from ships. 5. Conveyor Systems: Conveyor systems are used for continuous movement of steel billets along a predefined path. They can be used to transport billets between different stages of the production process or to load and unload them from trucks or trains. 6. Roller Tables: Roller tables are used for transferring steel billets from one conveyor or machine to another. They typically consist of a series of rollers that allow for smooth and controlled movement of the billets. 7. Magnetic Lifters: Magnetic lifters use an electromagnetic field to lift and transport steel billets. They are particularly useful when handling ferrous materials, as the magnetic force allows for secure gripping and easy movement. 8. Palletizers: Palletizers are used to stack and organize steel billets on pallets. They can automatically arrange the billets in a specific pattern, making them suitable for storage or transportation. Each type of equipment has its own advantages and is used in specific applications based on the requirements of the steel production process. The selection of the appropriate handling equipment depends on factors such as the size and weight of the billets, the distance they need to be transported, and the specific needs of the facility.

- Q: Are there any international standards for steel billets?

- Yes, there are international standards for steel billets. The most commonly recognized standards for steel billets include ASTM (American Society for Testing and Materials), BS (British Standards), and EN (European Standards). These standards ensure the quality, composition, and dimensions of steel billets, promoting consistency and compatibility in international trade and manufacturing processes.

- Q: Can steel billets be used for marine applications?

- Yes, steel billets can be used for marine applications. Steel billets are often used as a raw material for various marine components and structures. Due to their high strength and durability, steel billets are well-suited for marine applications that require resistance to corrosion, impact, and harsh environmental conditions. They can be used to manufacture ship hulls, propeller shafts, marine pipelines, offshore platforms, and other marine structures. Additionally, steel billets can be further processed and shaped into desired forms to meet specific requirements for marine applications.

- Q: What is the average price of steel billets?

- The average cost of steel billets may vary due to various factors such as market conditions, supply and demand dynamics, and the grade and quality of the billets. It is crucial to acknowledge that global economic influences, such as raw material expenses, energy prices, and trade policies, can cause fluctuations in the average price. To obtain an accurate understanding of the average steel billet price, it is advisable to consult industry reports, trade publications, and market analysis platforms that offer updated information on steel prices. Additionally, seeking advice from steel suppliers and manufacturers or engaging in negotiations with multiple sources can aid in determining the prevalent average price within a specific region or market.

- Q: What are the common alloys used in the production of steel billets?

- The common alloys used in the production of steel billets are primarily carbon and manganese. Carbon is added to increase the hardness and strength of the steel, while manganese is added to improve the steel's toughness and hardenability. Additionally, other alloying elements such as silicon, nickel, chromium, and vanadium may be added in smaller amounts to further enhance specific properties of the steel, such as corrosion resistance, heat resistance, or wear resistance. These alloying elements help create a wide range of steel grades with varying characteristics that can be tailored to suit different applications and industries.

- Q: Can steel billets be used in the production of utensils and cutlery?

- Yes, steel billets can be used in the production of utensils and cutlery. Steel billets are typically processed and shaped into various forms such as sheets, bars, or rods, which can then be further manufactured into utensils and cutlery items through processes like forging, casting, or stamping.

- Q: How are steel billets used in the production of industrial valves?

- Industrial valves rely on steel billets as a vital element in their production. These billets serve as the primary material for manufacturing valve bodies, which constitute the main structural component of the valve. To initiate the production process, steel billets undergo heating in a furnace, raising them to a specific temperature. This heating process is crucial, as it renders the billets malleable and easily moldable into the desired valve body design. Once the billets attain the necessary temperature, they are transferred to a forging press, a specialized machine. In this press, significant pressure is applied to the heated billet, causing it to assume the shape of a valve body. This forging process ensures that the valve body possesses strength, durability, and the ability to endure high pressures and temperatures encountered in industrial applications. Following the forging process, the valve bodies undergo machining to achieve the final shape and dimensions. This involves the utilization of cutting tools to eliminate any surplus material and refine the surface finish. The machined valve bodies then undergo a quality inspection to guarantee compliance with the required specifications and standards. After the valve bodies reach the desired condition, they undergo additional processes like heat treatment and surface coating. These treatments enhance their strength, resistance to corrosion, and overall performance. Consequently, the valves become capable of withstanding harsh operating conditions and enjoy a prolonged service life. In conclusion, steel billets are of utmost importance in the production of industrial valves. They undergo heating and forging to create the valve bodies, which serve as the foundational structure of the valves. Through subsequent processes like machining, heat treatment, and surface coating, the billets transform into high-quality valves that effectively regulate the flow of fluids or gases in diverse industrial applications.

- Q: What is the size range of steel billets?

- The size range of steel billets can vary depending on the specific requirements of the industry or application. However, in general, steel billets are typically produced in square or rectangular shapes, with dimensions ranging from 100mm to 200mm in width and height, and lengths ranging from 3 to 12 meters. These dimensions can be customized based on the intended use of the billets, such as for forging, rolling, or further processing into finished steel products.

- Q: What are the different types of steel billet reheating furnaces?

- There are several different types of steel billet reheating furnaces used in the metal industry. These furnaces are designed to heat steel billets to a specific temperature before they are further processed or shaped into various end products. The main types of steel billet reheating furnaces include: 1. Pusher Type Furnace: This type of furnace uses a pusher mechanism to move the billets through the furnace. The billets are loaded onto a roller conveyor and pushed into the furnace using mechanical pusher plates. As the billets move through the furnace, they are heated by the combustion gases or electrical heating elements. 2. Walking Beam Furnace: In a walking beam furnace, the billets are placed on a series of moving beams or skids. These beams move in a continuous loop, carrying the billets through the furnace. As the billets move, they are heated by the burners or electrical heating elements located above and below the beams. 3. Rotary Hearth Furnace: This type of furnace consists of a rotating hearth on which the billets are placed. The hearth rotates, bringing the billets through different temperature zones within the furnace. The billets are heated by the burners or electrical heating elements located above the hearth. 4. Continuous Furnace: A continuous furnace is a type of furnace where the billets are continuously fed into one end and discharged from the other end. The billets move through the furnace on a conveyor belt or roller conveyor, being heated by the combustion gases or electrical heating elements as they pass through. 5. Walking Hearth Furnace: In a walking hearth furnace, the billets are placed on a hearth that moves in a reciprocating motion. The hearth moves back and forth, bringing the billets through the furnace. The billets are heated by the burners or electrical heating elements located above and below the hearth. Each type of steel billet reheating furnace has its own advantages and is suitable for specific applications. The choice of furnace depends on factors such as the required heating capacity, the size and shape of the billets, the desired temperature profile, and the energy efficiency requirements.

- Q: How are steel billets used in the construction of bridges?

- Steel billets are used in the construction of bridges as raw materials for manufacturing various structural components such as beams, columns, and girders. These billets are heated and then rolled into the required shapes and sizes to form the framework of the bridge. They provide strength, durability, and load-bearing capacity, enabling the bridge to withstand heavy traffic and environmental forces.

Send your message to us

Alloy steel billet square prime from china

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 31264 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords