Butterfly Valve DN200 Wafer Type BS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Manual Wafer Butterfly Valve Description:

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve.

2.Main Features of the Manual Wafer Butterfly Valve

1.Square and short neck. Easy to stick scutcheon and cost saving.Nominal bore mm 20 25 32 40 50 65 80 100 125 150 200

2. The material of valve body: cast iron, cast steel, cast stainless steel and so on.

3. Pressure grade: 1.6Mpa, 4.0Mpa, 6.4Mpa

4. Connecting type: flange coupling

5. Temperature range: normal temperature -20---230ºC the thermal slug type -60---450ºC

6. Operation form: automatic open or close

7. Flow characteristic: equal percentage, linearity

8. Leakage: single-base valve: 0.01* rating Kv

9. double-base valve, sleeve valve: 0.5%* rating Kv

10.Cast hole. Flange connection meet ANSI 125/150# DIN PN10/16 BS4504 PN10/16 in the meanwhile.

11.Soft seat. Replaceable. Increase of service life.

12.Double half shaft without pin.

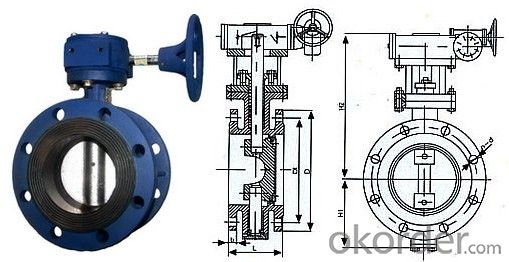

3. Manual Wafer Butterfly Valve Images:

4.Manual Wafer Butterfly Valve Specification:

5.FAQ

1. What is manual wafer butterfly valve?

A: Wafer style is the more common of the two and is less expensive than the lug style. The wafer style butterfly valve is just about the standard. It ís so common that no one even bothers to use the word "wafer" when ordering a butterfly valve. It is taken for granted that if a butterfly valve is ordered, a wafer style will be received.

2. How about the Installation of the Wafer Style Butterfly Valve?

A: Butterfly valves are installed by inserting the valve between two flanges using bolts or studs and nuts to hold it all together. This type of installation, of course, makes it impossible to disconnect just one side of the piping system from the valve. That benefit is received using the lug style valve.

3. What is the working principle of manual wafer butterfly valve?

A: A butterfly valve is from a family of valves called quarter-turn valves. In operation, the valve is fully open or closed when the disc is rotated a quarter turn. The "butterfly" is a metal disc mounted on a rod. When the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid. The valve may also be opened incrementally to throttle flow.

- Q: So I was diagnosed with a bicuspid aortic valve a couple months ago, I am 20 now and I was told that the defect normal dosent cause problems untill late 30's-40's. I have been having chest pains and at times sever palpitations. Has anyone eles gone through this? Anyone older that has experience with this problem?

- Yes okorder /

- Q: HAS ANYONE HAD VALVE REPLACEMENT (WITH PIG VALVE) OPEN HEART SURGURY. WHAT WAS THE RESULTS? HOW DO YOU FEEL NOW?

- my brother had it done in 1977 he chose the pigs valve because he was so young(19) and it has the most longevity. the only problem he had was alot of scar tissue developing around the attached portion and that should regularly be monitored. he lived another 11 years that he wouldn't have otherwise best of luck to you

- Q: I have a 2000 jeep grand cherokee v8 4.7L it has a stuck valve making knocking noises my question is can i still drive it !? or is too dangerous

- For 1 how do you know it has a stuck valve , if you know that you know how to get it unstuck (pb-blaster ) or something like that , or is it carbon holding it open if it is you will need to pull the head becouse the head of the valve will come off and damage the piston and the block , good luck.30 years exp on cars and big trucks

- Q: hii have just found out i have a genetic disease called multi valve prolapse but i want more info about itwhat are the symptoms? can it kill me? any info will help!!thank you

- Do you mean Mitral valve prolapse? The mitral valve helps blood on the left side of the heart flow in one direction. It closes to keep blood from moving backwards when the heart beats (contracts). Mitral valve prolapse is the term used when the valve does not close properly. It can be caused by many different things. Most people have no symptoms, but some people have chest pain, a rapid pulse, awareness of heartbeats, migraine headaches, fatigue, and dizziness. In a small number of cases, the prolapse can cause blood to leak backwards. This is called mitral regurgitation. Mitral valves that are structurally abnormal can raise the risk for bacterial infection. Some forms of mitral valve prolapse seem to be passed down through families (inherited). Mitral valve prolapse has been associated with other genetic disorders.

- Q: I am doing a big project on Valve and it's games. I am currently doing some research on the company and wanted to see if anyone had any interesting facts or information about Valve that may be useful when doing research, thank you. :)

- Valve Corporation Information

- Q: i have seen the wrting M/T on some valve covers and was wondering what that meant

- i would say thats the name of the valve pans.

- Q: Holding my right hand up, I am a newbie :) any help is greatly appreciated.a) Comparing the shape of the valve to a golf tee, what is the correct name for the thinnest section of the valve(the part of the golf tee that goes into the ground)b) What is the correct name for the widest section of the valve(the part of the golf tee that the ball is placed on.c) The cylinder that the valve moves up and down in, is it just called the valve cylinder?d) In the valve cylinder?, how does the widest part of the valve keeps things sealed. Does it use a ring(simmilar to pistons) or is it some type of gasket material or is it just zero clearance metal to metal.e) The section of the (valve cylinder?) that is above the seal point or basicaly where the valve spring and the thinnest part of the valve is, does oil flow through here?f) Do (valve cylinders?) generate enough heat to warrant the need for coolant?Newbie City, I know. Any help is GREATLY appreciated.TY

- stem, surface, valve guide, o rings in some. some valve guides are plastic with no clearance. yes oil flow, yes water flows through the heads to cool vales and head.

- Q: my friend needs a flap valve replacement. does anyone no how serious this is, i dnt wanna lose my best friend?!!!

- Its heart surgery, which is riskier than many other surgeries, but valve replacement is routine procedure. There's a variety of different procedures that are used and several different types of replacement valves. Some valves can be repaired and some need to be replaced. Repairs usually give a person a normal or nearly normal valve that will last forever. Valve replacements don't work quite as wells as repairs and they usually need to be replaced in a decade or so. Most people can have the valved replaced by threading a scope through the arteries or using tiny incisions, but some people require open heart surgery. My friend had one of his valves replaced with a valve made from a pig heart and he was only in the hospital one night, and back to work a week later.

- Q: I have a trumpet, but unintentionally dropped it. When I started playing, I noticed that the first valve was very sticky. Therefore, I decided to put some oil on it. Despite the oil helping a lot, the valves are still sticking a bit when I push them down, as the key still stays in the valve for a few second before coming up again. It could possibly have a slight dent, but when I opened the valve, I did not see any damage at all. Are there any suggestions? And if it is dented how much would it cost to repair it?

- My valves have had many issues over the past few years. Your problem is either 1. horn is dirty 2. there is a tiny dent (even 1/2mm is enough to stop the valve, happened to me last month). If your horn is dirty, there are plenty of youtube videos on how; it generally involves using water and rising all the gunk out. You could also have too much oil buildup. If there is a dent, don't even try to repair it yourself--it is waaaaay to hard, and you'll ruin the instrument even more. Take it to the store; it should only cost $20-30. I suggest you clean the trumpet first and then try to get it fixed if it is not good.

- Q: i have a 1991 rm125 and i want to open the power valves myself can anyone tell me how to do thisTHANKS!

- remove the carb abd intake manifold, they are inbetween the intake and reed cage. you will have to rejet .

Send your message to us

Butterfly Valve DN200 Wafer Type BS Standard

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords