4 Foot By 8 Foot Brushed Aluminum Sheets for Ceiling Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Brushed Aluminum Sheet for Ceiling Decoration

Aluminum Sheets are strengthened and cut from raw materials with different alloys, such as AA5005, AA5052, etc. They are easy for processing in different shapes, good in intensity and can be quickly installed. Aluminium Sheets for Energy Saving Curtain Walls are good in energy saving, weather resistance, fire resistance, easy for maintenance and with many colors.

Aluminium Sheets for Energy Saving Curtain Walls are widely used in construction of metal walls, metal ceilings, car decoration, advertizing panels, etc.

2.Main Features of Brushed Aluminum Sheet for Ceiling Decoration

•High intensity

•Easy to be processed and shaped

•Weather resistance

•Anti-pollution & environment protection

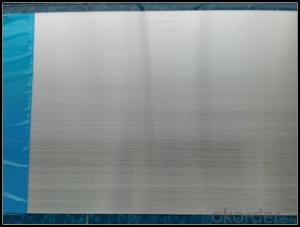

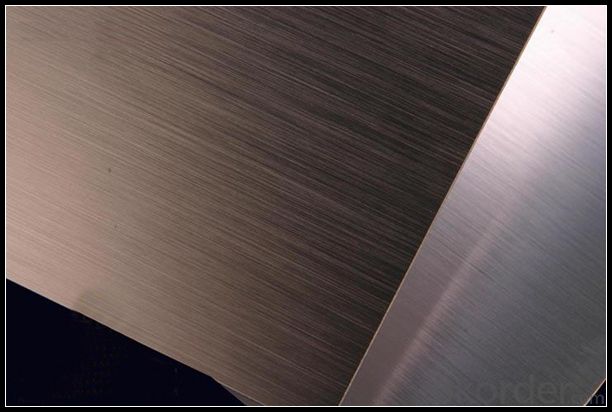

3. Brushed Aluminum Sheet for Ceiling Decoration Images

4.Specification of Brushed Aluminum Sheet for Ceiling Decoration

Alloy Number | AA5XXX |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

5.FAQ

A.What about inspections to guarantee quality?

For each order for Aluminum Sheets with Mill Finished Surface AA5XXX, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order for Aluminum Sheets with Mill Finished Surface AA5XXX in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported aluminium sheets?

We have exported aluminum sheets to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: I want to use one aluminum bottle, rather than several plastic ones. And this may sound stupid, but will an aluminum water bottle be safe to put in the fridge?

- Carefull with using Aluminum to store water you are going to drink. I would use a ceramic or glass container instead. Aluminum is recognized as a NEUROTOXIN. It has no biological function in the metabolisms of human beings. It can bio accumulate in the body and competes with calcium for absorption in the body. There is growing scientific evidence that links increase intakes of aluminum with Alzheimer disease and other brain degenerative disorders. (High levels of Aluminum have been found in the brains of deceased Alzheimers patients, and Aluminum can pass the blood brain barrier) In my sources I have some links to scholarly articles on this matter and the Wikipedia article on Aluminum Please do more research into this matter you will uncover more Good Luck

- Q: Can aluminum sheet withstand heavy loads?

- Yes, aluminum sheet can withstand heavy loads. Aluminum is known for its high strength-to-weight ratio, making it an excellent choice for applications that require durability and load-bearing capabilities. Aluminum sheets are commonly used in industries such as aerospace, automotive, construction, and marine, where heavy loads are involved. Additionally, aluminum's inherent corrosion resistance further enhances its ability to withstand heavy loads over extended periods. However, it is important to consider the specific grade and thickness of the aluminum sheet, as different alloys and thicknesses have varying load capacities.

- Q: What kind of paint would you like to paint on the aluminum plate?

- Nitro paint, polyester paint can be mainly your base, you should use atomic ash treatment before you can use, otherwise it will peel off

- Q: How is aluminum obtained from its ore?

- Aluminum is obtained from its ore through a process called the Bayer process. First, the ore, called bauxite, is crushed and mixed with a solution of sodium hydroxide. This mixture is then heated and pressurized in a digester, causing the aluminum oxide to dissolve and form sodium aluminate. After the impurities are removed, the sodium aluminate solution is cooled and treated with carbon dioxide, which converts it into aluminum hydroxide. Finally, the aluminum hydroxide is heated and transformed into pure aluminum metal through electrolysis.

- Q: Aluminum is put into copper chloride and how can you tell what happens to them visually?

- The aluminum metal appears to be turning into copper, but it is actually just removing the metallic copper from its compound state. The Aluminum is oxidized and loses e-, becoming Al 3+ and the copper ions are reduced (they accept those e-) to form solid copper precipitate. The aluminum ions and chloride ions remain in the solution. The reaction will only occur in water and occurs because the transfer of electrons from the aluminum to the copper results in a more stable system.

- Q: Can the aluminum sheets be bent or formed into different shapes?

- Yes, aluminum sheets can be easily bent or formed into different shapes due to their malleability and ductility.

- Q: are there any hazards in aluminium?

- Some. The chemical aluminum can get into your blood accumulate. Years ago, there was a study of weather blood aluminum was the cause of Alzheimer disease. Was proven not to be. But that study helped to reduce the amount of aluminum in deodorant sticks.

- Q: Can aluminum sheets be bent without breaking?

- Yes, aluminum sheets can be bent without breaking. Aluminum is a highly malleable and ductile metal, which means it can be easily shaped and bent without fracturing or cracking. This property makes aluminum an ideal material for various applications, including the manufacturing of aircraft, automobiles, and household items. The flexibility of aluminum sheets allows for the creation of intricate designs and complex shapes, making it a highly versatile material. However, it is important to note that the thickness and grade of the aluminum sheet can influence its bendability. Thicker sheets may require more force and specialized tools to achieve the desired bend, while softer grades of aluminum may be more easily bent.

- Q: How to carry out drawing process in aluminium plate

- The process of repeated scraping is an essential step in the production and processing, and we can not forget. The second is in the process of the film, to make the drawing processing after more shiny, look more beautiful, the film is the key technology in the field of production and processing. Should be careful, careful, can not be careless, such a careful and responsible work attitude, for drawing aluminum plate each place to do the details of the treatment, so that the filaments will be dense and bright.

- Q: What are the different manufacturing methods for aluminum sheets?

- Aluminum sheets can be manufactured using various methods, each possessing its own unique characteristics and applications. 1. Rolling, the most commonly employed method, involves passing large aluminum slabs through a series of rollers to reduce thickness and increase length. This process ensures consistent thickness and excellent surface finish. 2. Another method, extrusion, utilizes a heated aluminum billet forced through a die, resulting in a continuous sheet. Extrusion allows for the creation of complex shapes and profiles, making it suitable for applications in building construction and automotive components. 3. Casting involves pouring molten aluminum into a mold, allowing it to cool and solidify into a sheet shape. This method is often used for producing thicker sheets or those with specific alloy compositions. Casting offers unique properties and is prevalent in industries such as aerospace and defense. 4. Cladding entails bonding a thin layer of aluminum to another material like steel or composite materials. This combines the desirable qualities of aluminum, such as corrosion resistance and lightweight, with the strength and durability of the base material. Clad aluminum sheets find common use in construction, transportation, and electrical industries. 5. Powder metallurgy involves forming aluminum sheets from powdered aluminum particles. The powder is compacted into the desired shape and then sintered at high temperatures to fuse the particles together. This method is ideal for producing complex shapes and can improve mechanical properties. Considering the desired properties, application, and cost considerations, it is crucial to select the most appropriate manufacturing method for aluminum sheets based on the specific project requirements.

Send your message to us

4 Foot By 8 Foot Brushed Aluminum Sheets for Ceiling Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords