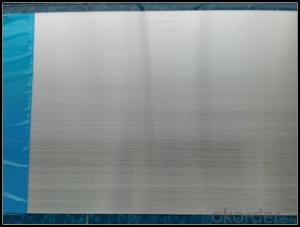

4x8 Brushed Aluminum Sheets for Curtain Wall 1050 1060 H12 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. specification aluminium alloy sheets/plates

Material | 1,2,3,5,6,7,8 series |

Temper | O, F, H14, H34, H32, H112, T4, T6 |

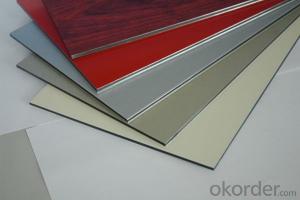

Surface treatment | Mill Finish,Anodized,Eletropharesis,Powder Coated, Wooden Finish, Polish |

Colour | Silver,Black,Red,Blue,or as required |

Length | As required |

Shape | Plainen,bossed,or as per the drawings and samples |

Fabrication | cutting,drilling,punching,bending,etc |

Tolerances | As per your requirements |

Package | inner plastic paper interleaving each piece profile,outer fixed by plywood, or as per your requirements |

Payment terms | TT |

Price terms | FOB;CIF;CNF |

Delivery time | 15-20 days after order confirmation |

Certification | ISO 9001:2008; |

Application | Decorations,Fence,Building,Aviation industry,Mechancal equipment |

Capacity | 5000 tons per month |

Min order quantity | 5 Metric ton |

Chemical Composition | %SiFeCuMnMgCrNiZnTiZrMin0.000.003.800.301.200.00 0.000.00 Max0.100.124.400.901.800.10 0.250.15

|

2. Properties:

1.High hardness, hard aluminum series.

2.Fair corrosion resistance. Heat treatable

3.Good workability. Good appearance

4.High quality and reasonable price.

5.Our product is your best choice.

3.Size

Thickness: 0.15-3.0mm(Tolerance:+/-0.02mm)

Width:150-2000MM(Tolerance:+/-1mm)

Length:600-6000MM(Tolerance:+/-1mm)

4.Products category

Thick plate | PS plate |

Oversized plate | Backing plate |

Soft alloy sheet | Contour plate |

Hard alloy sheet | Bottle caps sheets |

Equipment cabinet plate | Can lid plate |

Thread plate | Plain aluminum sheet |

Curtain wall plate | Quenched plate |

High grade plate | Pre-stretching plate |

5. Capacity of aluminum sheets/plates

Our main products are aluminum alloy materials, including aluminum alloy seamless

pipes, aluminum alloy welded pipes, aluminum alloy cold drawn pipes, aluminum alloy

extruded pipes, aluminum alloy extruded bars, aluminum alloy plates and sheets, and

aluminum alloy coils, aluminum alloy forging, etc .

Aluminum alloy Typical Mechanical Properties

Grades and status | Tensile strength (25°C MPa) | Yield Strength (25°C MPa | Hardness force 500kg 10mm | Elongation thickness 1.6mm(1/16in) |

5052-H112 | 175 | 195 | 60 | 12 |

5083-H112 | 180 | 211 | 65 | 14 |

6061-T651 | 310 | 276 | 95 | 12 |

7050-T7451 | 510 | 455 | 135 | 10 |

7075-T651 | 572 | 503 | 150 | 11 |

2024-T351 | 470 | 325 | 120 | 20 |

6. Application

Building material, insulation, shoes and tens eyes, corner beads, automotive industrial,

POP can bottle and cap, deep-proceeding case, light industry,

TV back board, PP caps, cell mask and so on.

7.Photos

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Yes, aluminum sheets are suitable for use in food processing or packaging industries. Aluminum is a widely used material in the food industry due to its excellent properties such as being lightweight, corrosion-resistant, and having good thermal conductivity. It is also impermeable to moisture, oxygen, and light, which helps to preserve the quality and freshness of food products. Additionally, aluminum sheets can be easily formed into various shapes and sizes, making them versatile for different packaging requirements.

- Q: How do you prevent galvanic corrosion when using aluminum sheets with saltwater?

- To avoid galvanic corrosion when utilizing aluminum sheets in saltwater, there exist several steps that can be taken: 1. The application of protective coatings is one effective method. This can be accomplished by employing specialized marine-grade paints or coatings specifically designed to hinder corrosion in saltwater environments. These coatings act as a barrier between the aluminum and the saltwater, effectively reducing the probability of galvanic corrosion. 2. Another approach involves the utilization of isolation materials, such as rubber or plastic gaskets, between the aluminum sheets and any dissimilar metals that may come into contact with them. These materials prevent direct contact between the aluminum and other metals, thereby minimizing the risk of galvanic corrosion. 3. Galvanic corrosion inhibitors can be added to the saltwater to help mitigate the risk of corrosion. These inhibitors function by creating a protective layer on the aluminum surface, thereby preventing the electrochemical reactions that lead to galvanic corrosion. 4. The implementation of cathodic protection techniques can also assist in preventing galvanic corrosion. This entails connecting the aluminum sheets to a sacrificial anode made from a more active metal, such as zinc or magnesium. The sacrificial anode corrodes instead of the aluminum, thus safeguarding it from galvanic corrosion. 5. Proper maintenance is crucial in preventing galvanic corrosion. Regularly cleaning and maintaining the aluminum sheets is essential, as saltwater and other contaminants can accumulate on the surface, promoting corrosion. Cleaning the sheets with fresh water and eliminating any salt deposits can help prolong their lifespan and reduce the risk of galvanic corrosion. It should be noted that these preventive measures should be implemented alongside proper material selection and design considerations. Seeking guidance from corrosion experts or engineers specializing in marine applications can provide further insight into the specific requirements and best practices for preventing galvanic corrosion when using aluminum sheets in saltwater.

- Q: I've created a sculpture out of aluminum foil, but it's pretty flimsy. What can I paint or cover it with that would harden and support it? I was thinking a resin or something, but I have no experience with resins or epoxies... Any suggestions?

- Rigid Wrap is plaster-infused gauze. You can buy it at the art supply store or at a medical supply store. The latter is cheaper. It comes on a roll so you can cut off small chunks. Wet each piece and apply it to your sculpture. The first layer may be the most difficult. I would wrap the plaster gauze around the structure so the gauze overlaps gauze. It may not stick to the aluminum but it will stick to itself. Start at the bottom and let it dry, then add another layer. As mentioned, adding too much may compromise the structure so work slowly and allow time to dry between layers.

- Q: Do 101 aluminum sheets have any specific fire resistance properties?

- Indeed, specific fire resistance properties are possessed by a total of 101 aluminum sheets. With a melting point of 660 degrees Celsius (1220 degrees Fahrenheit), aluminum can endure high temperatures before the onset of melting. Furthermore, due to its low combustion point, aluminum does not easily ignite. In the event of a fire, the aluminum sheets serve as a barrier that hinders the spread of flames. Furthermore, the burning of aluminum results in the formation of a protective oxide layer on its surface, which effectively impedes the advancement of the fire. Nevertheless, it is important to acknowledge that although aluminum exhibits fire-resistant characteristics, it is not entirely impervious to fire and can still suffer damage or deformation when subjected to intense heat.

- Q: As for cast aluminum sheet or wrought one, which one has faster heat conduction?

- 1,duralumin: it's the alloy of aluminum, copper, magnesium, manganese and other metals. it's suitable for compacting by rolling, and it has a higher strength and hardness than common aluminum products. 2, aluminum: it contains many inpurities, is crisp and easy to be smashed.cast aluminum usually is secondary aluminum, and it is produced by remelting the collected old aluminum pots and spoons.3, wrought aluminum: it contains 98% aluminum and 2% or more inpurities, and is comparatively pure aluminum. its soft priority makes it suitable for being pressed into various shapes, aluminum pots,aluminum lunch box,aluminum sheets,aluminum wires,aluminum pipes are all made by wrought aluminum.you will know their defferences from their definition.

- Q: This question asks for methods to ensure that the connections between aluminum sheets are both secure and resistant to water leakage.

- <p>To ensure that the joints between aluminum sheets are secure and watertight, use a combination of sealants and appropriate fasteners. First, clean the surfaces to be joined thoroughly. Apply a high-quality, waterproof sealant along the joint. This sealant should be compatible with aluminum and resistant to UV, temperature changes, and water. Then, use corrosion-resistant fasteners such as stainless steel screws or rivets to join the sheets. Ensure that the fasteners are tightened correctly to prevent leaks. Additionally, consider using a gasket or a weatherstrip along the joint for added watertightness. Regularly inspect and maintain the joints to ensure ongoing watertight integrity.</p>

- Q: What are the standards and certifications available for aluminum sheets?

- There are several standards and certifications available for aluminum sheets, ensuring their quality and compliance with industry requirements. Some of the commonly recognized ones include: 1. ASTM International Standards: The American Society for Testing and Materials (ASTM) has developed a range of standards specifically for aluminum and aluminum alloys. These standards cover various aspects such as chemical composition, mechanical properties, and dimensional tolerances, ensuring consistent quality across different aluminum sheet products. 2. ISO 9001: The ISO 9001 certification is a globally recognized standard for quality management systems. Aluminum sheet manufacturers that are ISO 9001 certified have demonstrated their commitment to meeting customer requirements, continuous improvement, and adherence to strict quality control processes. 3. ASME Standards: The American Society of Mechanical Engineers (ASME) has established specific standards for aluminum sheet materials used in pressure vessels, piping, and other applications. These standards ensure the safety and reliability of aluminum sheets in critical applications. 4. MIL-Specifications: The United States Department of Defense (DoD) has developed military specifications (MIL-Specs) for various materials, including aluminum sheets. These specifications define the requirements for military-grade aluminum sheets, ensuring their suitability for specific defense applications. 5. EN Standards: The European Committee for Standardization (CEN) has developed a series of European Norm (EN) standards for aluminum and aluminum alloys. These standards cover various aspects such as chemical composition, mechanical properties, and surface finishes, ensuring compatibility and consistency across the European market. 6. RoHS Compliance: Restriction of Hazardous Substances (RoHS) compliance is crucial for aluminum sheets used in electrical and electronic equipment. This certification ensures that the aluminum sheets do not contain hazardous substances such as lead, mercury, cadmium, and certain flame retardants, thus guaranteeing their environmental safety. It is important for manufacturers and suppliers of aluminum sheets to comply with these standards and certifications to ensure the highest quality, safety, and suitability of their products for specific applications.

- Q: Is aluminium plate the same as aluminium alloy?

- Oh, No. aluminum contains only aluminum, and there are some other metals besides aluminium.

- Q: Are aluminum sheets suitable for electronics applications?

- Aluminum sheets prove to be an optimal choice for electronics applications as they possess remarkable conductivity and exhibit versatility as a lightweight metal. Such qualities render them suitable for a wide range of electronic components and their respective uses. Within the electronics industry, aluminum sheets find frequent application in heat sinks, enclosures, PCB substrates, and connectors. By utilizing aluminum sheets for heat sinks, electronic devices can effectively dissipate heat, guaranteeing optimum performance while averting the risk of overheating. Moreover, the durability, corrosion resistance, and electromagnetic interference shielding capabilities of aluminum make it a favored material for electronic device enclosures. These enclosures serve to safeguard delicate electronic components, ensuring both their functionality and safety. The superior thermal conductivity of aluminum sheets also makes them an ideal choice for PCB substrates. By employing aluminum sheets in this context, the generated heat from electronic components on the PCB can be efficiently dissipated, thus averting potential damage and ensuring proper circuit functionality. Additionally, when compared to other commonly used metals in electronics, such as copper, aluminum proves to be cost-effective. This factor contributes to its popularity for various electronic applications, particularly in mass production scenarios. To summarize, the impressive conductivity, durability, corrosion resistance, and heat dissipation qualities of aluminum sheets make them highly suitable for electronics applications. Their widespread use in the electronics industry spans across heat sinks, enclosures, PCB substrates, and connectors, offering numerous benefits in each context.

- Q: Are aluminum sheets suitable for decorative screens?

- Yes, aluminum sheets are suitable for decorative screens. They are lightweight, durable, and can be easily customized into various shapes and designs. Additionally, aluminum's corrosion resistance makes it suitable for both indoor and outdoor applications, making it a popular choice for decorative screens.

Send your message to us

4x8 Brushed Aluminum Sheets for Curtain Wall 1050 1060 H12 H14

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords