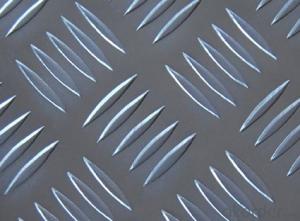

Aluminum Embossing Sheets - Diamond Pattern Aluminum Coil/Sheet with 5 Bars/Stucco Pattern

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Coil/Sheet of Diamond/ 5 bars/Stucco Pattern:

Aluminum Coil/Sheet of Diamond/ 5 bars/Stucco Pattern is widely used for decorative purposes in construction, packing and appliance. Aluminum Coil/Sheet of Diamond/ 5 bars/Stucco Pattern is also very commonly used for anti-shippery purposes in vehicles and pulic places.

2.Main Features of theAluminum Coil/Sheet of Diamond/ 5 bars/Stucco Pattern:

• Beautiful parten

• Good anti-slippery quanlity

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

3. Aluminum Coil/Sheet of Diamond/ 5 bars/Stucco Pattern

Alloy: 1050, 1060, 1070, 1100, 3003, 3004, 3005, 3105, 5052, 5083, 5754, 8011, 8006

Temper: H14, H16, H18, H22, H24, H26, H32, O/F

Thickness: 0.2mm-20mm

Width: 10mm-1500mm

4.FAQ

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: What can I do to remove the paint from the painted aluminum sheet?

- The aluminum need scraping, the car is not easy to enamel paint.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more).

- Q: What are the different alloys available for aluminum sheets?

- There are several different alloys available for aluminum sheets, each with its own unique properties and applications. Some of the most common alloys include: 1. 1100: This is a commercially pure aluminum alloy with excellent corrosion resistance, making it suitable for applications where high levels of corrosion resistance are required, such as in marine environments. 2. 3003: Another commercially pure alloy, 3003 offers good formability, high corrosion resistance, and moderate strength. It is commonly used for general sheet metal work, cooking utensils, and chemical equipment. 3. 5052: This alloy is known for its high fatigue strength and excellent corrosion resistance, particularly in saltwater environments. It is often used in marine applications, as well as for aircraft components and fuel tanks. 4. 6061: A heat-treatable alloy, 6061 exhibits good weldability and formability, along with high strength and excellent corrosion resistance. It is commonly used in structural components, such as frames and railings, as well as automotive parts. 5. 7075: This alloy is known for its high strength-to-weight ratio, making it ideal for aerospace applications and high-stress structural components. However, it is less corrosion resistant than other alloys and may require protective coatings in certain environments. These are just a few examples of the alloys available for aluminum sheets. The choice of alloy will depend on the specific requirements of the application, such as strength, corrosion resistance, formability, and cost. It is important to consult with a knowledgeable supplier or engineer to determine the most suitable alloy for your specific needs.

- Q: Are 101 aluminum sheets suitable for automotive applications?

- Yes, 101 aluminum sheets are suitable for automotive applications. 101 aluminum is a high-strength alloy that offers good formability, corrosion resistance, and excellent weldability. These properties make it a popular choice for various automotive components such as body panels, heat shields, and structural parts. Additionally, 101 aluminum sheets are lightweight, which helps improve fuel efficiency and overall vehicle performance. Overall, 101 aluminum sheets are well-suited for automotive applications due to their strength, formability, corrosion resistance, weldability, and lightweight characteristics.

- Q: will it influence powder injection effect after wiping the oil contamination on the surface of aluminum sheet?

- the surface should be kept clean to avoid the influence of oil contamination.

- Q: Is it possible to utilize aluminum sheets in a home renovation project?

- <p>Yes, you can use aluminum sheets for your home renovation project. Aluminum is a versatile material known for its strength, durability, and resistance to corrosion. It's commonly used for roofing, siding, and even for decorative purposes. Aluminum sheets are lightweight, easy to install, and can be painted or coated to match your home's aesthetic. They also offer good thermal performance and can be recycled, making them an environmentally friendly choice. However, it's important to consider the specific requirements of your project, such as the local climate, design preferences, and budget, to ensure aluminum is the best fit.</p>

- Q: What are the potential environmental issues that arise from the use of aluminum sheets?

- <p>Yes, there are environmental concerns related to using aluminum sheets. The production process is energy-intensive and contributes to greenhouse gas emissions. Additionally, the mining of bauxite, the primary source of aluminum, can lead to deforestation and habitat destruction. The disposal of aluminum waste can also lead to pollution if not properly managed. However, aluminum is highly recyclable, which can mitigate some of these concerns if recycling practices are adopted widely.</p>

- Q: Hello, I dont really know anything about using a drill or cutting through metal or wood. the thing is I have a project in which I have to drill some holes in 0.04in aluminum. but I really dont know if can use regular drill bits used for drilling wood to drill the holes in my aluminum chassis. do I need to buy other drill bits for cutting metal or can I use the same ones Ive seen used for cutting wood? can I even use the same kind of drills, or do I NEED a huge bench drill with stepper bits?thanks

- Aluminum is softer than steel, so you could just use the ordinary bits that you use for wood, with a hand drill. For cleaner holes, you might want to put wood behind the aluminum as a backing. Also, if you squirt a drop of oil onto the drill area, that will help. If you're trying to drill a really large hole, it might be better to drill small ones, and enlarge with a round file.

- Q: Is it possible to substitute aluminum sheets for wood siding in construction?

- <p>Yes, you can use aluminum sheets to replace wood siding. Aluminum siding is a popular alternative to wood for several reasons. It is lightweight, durable, and resistant to rot, insects, and moisture. It also requires less maintenance than wood and can be painted to match various aesthetic preferences. However, it's important to consider factors such as insulation properties, cost, and the look you want to achieve, as aluminum may not perfectly mimic the appearance of wood. Always consult with a professional to ensure proper installation and compatibility with your home's architecture.</p>

- Q: Are aluminum sheets suitable for architectural roofing?

- Indeed, architectural roofing can indeed be accomplished with aluminum sheets. Aluminum, being a lightweight substance, is resistant to corrosion, which renders it an optimal selection for roofing purposes. Moreover, it is highly durable and capable of withstanding severe weather conditions, such as extreme temperatures, UV radiation, and strong winds. To add to its appeal, aluminum sheets are accessible in various colors and finishes, granting flexibility in terms of design and aesthetics. Furthermore, aluminum proves to be an environmentally friendly and sustainable material as it can be recycled perpetually without compromising its properties. In summary, aluminum sheets exhibit outstanding performance and versatility, thus making them a favored option for architectural roofing.

- Q: Are aluminum sheets suitable for solar panel applications?

- Yes, aluminum sheets are suitable for solar panel applications. Aluminum is a lightweight and durable metal, making it an ideal material for constructing the frames of solar panels. Its corrosion resistance ensures that the panels can withstand outdoor conditions and last for a long time. Additionally, aluminum has a high thermal conductivity, allowing it to dissipate heat effectively, which is beneficial for solar panels as they generate heat during operation. Moreover, aluminum is a highly recyclable material, aligning with the environmentally friendly nature of solar energy. Overall, aluminum sheets are a reliable and practical choice for solar panel applications.

Send your message to us

Aluminum Embossing Sheets - Diamond Pattern Aluminum Coil/Sheet with 5 Bars/Stucco Pattern

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords