Steel Ceiling Grid Bonroy Suspension Ceiling Tee / Acoustic Ceiling Tgrid Accessories

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Flat Suspension Grids) Description

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

t grids ceiling system

1 Materiel: Galvanized steel & prepainted

2 Size: H38&H32 H15

3 System: flat & groove

fut ceiling t grid

Materiel: Hot dipped galvanized steel & prepainted

Surface:Baking Finish

System: flat ceil & groove ceiling

2,Main Features of the (Flat Suspension Grids)

Shape:Plane,groove

Groove T bar ceiling grid (FUT) & FUT Ceiling Grid system is made of high quality prepainted galvanized steel,which guarantee the characters of moisture proof,corrosion resistanct and color lasting.The automatic cold roll forming and punching machineries guarantee the high precision.

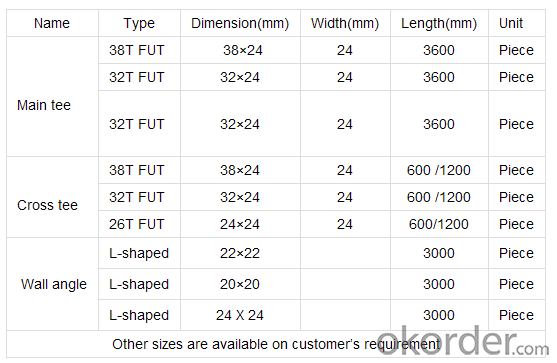

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

3,(Flat Suspension Grids) Images

4,(Flat Suspension Grids) Specification

5,FAQ of (Flat Suspension Grids)

1. Convenience in installation, it shortens working time and labor fees.

2. Neither air nor environment pollution while installing. With good effect for space dividing and beautifying.

3. Using fire proof material to assure living safety.

4. Can be installed according to practical demands.

5. The physical coefficient of all kinds Suspension

Standard size:

1. Main tee:38x24x3000/3600mm(10'),(12'); 32x24x3000/3600mm(10'),(12')

2. Cross tee:32x24x1200mm (4');26x24x1200mm (4')

3. Cross tee:32x24x600mm (2'); 26x24x600mm (2')

4. Wall angle:24x24x3000mm (10'); 22x22x3000mm (10'); 20x20x3000mm (10')

5. Thickness:0.25mm,0.27mm,0.3mm,0.35mm,0.4mm

6. The length, thickness and color can be provided in accordance with customers'

requirements.

- Q: I am trying to hang a 30 LBS item from a drop ceiling, with no luck. I would like to use 2-3 eyebolts to distribute the weight, but everytime I think I figured it out, it pulls right through. The ceiling can't be very thick at all. Can this be done?

- 30 lbs is quite a bit of weight. You will need to screw into a joist. Ay type of toggle bolt just through the drywall will not hold it.

- Q: I want to put in a drop ceiling and recessed lights in a basement. Do I hang the ceiling first and then install the can lights? Or do I do the lights first and then do the ceiling?

- You put the lights up first. They have to be fastened to the floor joists in your basement ceiling.

- Q: I need to attach track lighting in an office with acoustical tiles. Can I screw the track directly into the metal tracks of the suspended ceiling? (running power is not a problem to the track, but the tiles have to stay)

- No! You need to install 'T' bar clips to the T bars. Your track will attach (snap onto) the clips. Depending on the brand of track lighting you are using, the clips may be available at your local (big box) hardware store. Screwing straight to the T bars is asking for a short.

- Q: Main beams for the ceiling grid come in 12' lengths. What if a room is twice that in length? Is there a way to interlock those things together? I know that the secondary 4' pieces lock onto the main beams, though.

- You are correct that the Main T's are 12' long and yes you can connect those with each other. Here is how you do it! If you do not own a rotary laser level you can probably rent one at an tool rental store. Alternatively you can also measure the desired height from the floor (giving it is level) and snap a line with an chalk line on every wall. Now you will mount the wall angle along the walls (try to hit studs normaly16 on center) once you completed this you need to install hangers every 2-4' to hang your wire from ( your rafters may be 24 on center) I would use the recommended screws for it, if you have the framing in the ceiling exposed you also can hang the suspension wire from the rafters that will support your T's. to verify level you can use a level or pull a string across your main T's. Now you can install all your cross T's they come in 2' + 4' length you should have your main T's spaced accordingly. Now you can insert the Ceiling Tile, install only on row at the time if you want to install Bat Insulation on top of it. If you planing on installing recess Lights I would install those drops before the main T's because it is easier to move your grid out the way. If you want to use florescent lights you need to support all 4 corners of your Main T's around the light fixture to support the weight. One last tip: Buy your supply s from an Distributor for Armstrong that will save you a bunch of cash in comparison to an Home Improvement Store like Lowe's or Home Depot Good Luck

- Q: My family bathroom and living room between the non-load-bearing walls, do not want to tear down all, just want to bathroom door from the left side of the wall to the right. Decoration said, do light steel keel wall to the left side of the door plug. So there will be no problems with the toilet tiles ah?

- The left side of the door plug, the plug network, pull hair! The next step on the line

- Q: Light steel keel paper gypsum board wall at the bottom of whether to concrete guide wall

- If you do not have moisture, you can not do it.

- Q: How many millimeters are the main keel spacing during the construction of the lightweight steel keel ceiling?

- Bears With the level of each wall in the room (column) angle out of the horizontal point (if the wall is longer, the middle is also appropriate to copy a few points) Pop-up line (level according to the ground is generally 500mm), from the level of the ceiling to the height of the design plus 12mm (a Layer of white plate thickness), with the powder line along the wall (column) pop-up line, that is, the tail of the keel down the skin line. Simultaneously, According to the ceiling plan, in the concrete roof pop-up main keel position. The main keel should be from the center of the ceiling to the two points, the largest Spacing of 1000mm, and marked the fixed point of the boom, the fixed point of the boom spacing 900 ~ 1000mm. Such as encountering beams and tubes The fixed point of the road is greater than the design and procedure requirements, and the fixed point of the boom should be increased.

- Q: Light steel keel divided into several

- The main specifications of the ceiling keel are divided into D38, D45, D50 and D60. (2) Product marking method The marking order of light steel keel is: product name, code, width of section shape, height, thickness of steel plate and standard number. Such as cross-sectional shape of "C" type, width of 50mm, height of 15mm, steel plate thickness of 1. Smm of the ceiling keel marked as: building light steel keel DC 5 0 XIS XI. SGBllg sl (3) appearance quality light steel keel shape to be smooth, angular, cut not allowed to affect the use of burrs and deformation. Galvanized layer is not allowed to have skin, from the tumor, shedding and other defects. For corrosion, damage, dark spots, pitting and other defects, according to the provisions of the method should be tested in accordance with the provisions of Table 2-81. Appearance quality inspection, should be 0.5m away from the product under the conditions of bright light, the visual inspection. Light steel keel surface should be galvanized rust, the double-sided galvanized: excellent not less than 120g / m * m, first-class goods is not less than 100g / m * m, qualified products not less than 80g / m *

- Q: I have a manufactured home and trying to finish the basement. I am stuck on how to install a ceiling being there are steel beams instead of wood therefor nothing to attach a grid to. Any ideas or anybody ever done this before?

- you could buy screws with a drill point and a hex head.attach with these to the metal beams drop down enough to clear obstacles support grid with wire hung from screws

- Q: My wife and I screw in wood into ceiling joist then put on piece of 4X8ft 1/2'' thick ultra light Sheetrock dry wall into ceiling with 1-5/8 drywall screw, with my wife and I holding it up I screw into the drywall into wood and let go then drywall falls or go through screw. What happened? Did we use the wrong screws? The screw tip touch the drywall.

- Or not enough screws, you need to use a fair number for a ceiling. You may want to go with another solution in a basement, though.

Send your message to us

Steel Ceiling Grid Bonroy Suspension Ceiling Tee / Acoustic Ceiling Tgrid Accessories

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords