Grade SAE 4140 Steel Price_Steel Round Bar Dimension

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Grade SAE 4140 Steel Price_Steel Round Bar Dimension

Details of Grade SAE 4140 Steel Price_Steel Round Bar Dimension

Name | Steel Round Bar |

Shape | Round Bar/Square Bar/Flat Bar/Plate/Wire |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Specification of SAE 4140 Steel Price_Steel Round Bar Dimension

1.Size of 4140 Steel Round Bar | ||||||||

Round bar | Diameter(mm) | Length (mm) | ||||||

20~800 | 3000~9000 | |||||||

Plate | Thickness(mm) | Width (mm) | Length (mm) | |||||

Max:800 | Max:2200 | Max:9000 | ||||||

The specification can be customized. | ||||||||

2.Chemical Compositons | ||||||||

Grade | C | Si | Mn | P | S | Cr | Mo | Ni |

42CrMo | 0.38~0.45 | 0.17~0.37 | 0.50~0.8 | ≤0.035 | ≤0.035 | 0.9~1.2 | 0.15-0.25 | ≤0.3 |

4140 | 0.40~0.45 | 0.15~0.35 | 0.75~1.0 | ≤0.035 | ≤0.040 | 0.8~1.1 | 0.15-0.25 | - |

SCM44 | 0.38~0.43 | 0.15~0.35 | 0.60~0.9 | ≤0.030 | ≤0.030 | 0.9~1.2 | 0.15-0.30 | ≤0.25 |

1.7225 | 0.38~0.45 | ≤0.40 | 0.60~0.9 | ≤0.025 | ≤0.035 | 0.9~1.2 | 0.15-0.30 |

|

3.Features of 4140 alloy steel | ||||||||

1. Chromium molybdenum alloy steel | ||||||||

2. Slightly higher carbon content then 4130 | ||||||||

3. Greater strength and heat treatment | ||||||||

4.Typical Applications | ||||||||

1. Applications in the oil and gas sector | ||||||||

2. Connection rods, collets, conveyor pins, | ||||||||

3. Gears, stem assemblies, | ||||||||

4. Pump shafts and tool holders | ||||||||

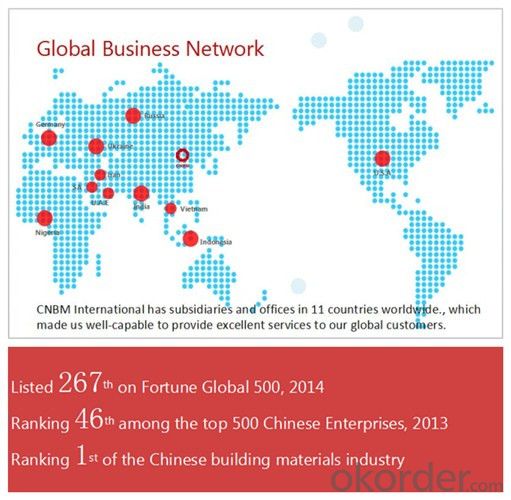

CNBM Introduction of SAE 4140 Steel Price_Steel Round Bar Dimension Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

Packaging & Delivery SAE 4140 Steel Price_Steel Round Bar Dimension

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: Can special steel be used in the construction industry?

- Yes, special steel can be used in the construction industry. It offers several advantages such as high strength, durability, and resistance to corrosion, making it suitable for various applications in construction, including beams, columns, and reinforced concrete structures. Special steel can also provide cost-effective solutions by reducing the need for additional materials and maintenance.

- Q: How does special steel perform in high-pressure and high-temperature environments?

- Special steel is specifically designed to perform exceptionally well in high-pressure and high-temperature environments. It possesses unique properties that enable it to withstand extreme conditions without undergoing deformation, corrosion, or failure. One of the primary characteristics of special steel is its high strength. It is engineered to have superior mechanical properties, such as excellent tensile strength, which allows it to resist the immense pressure exerted on it in high-pressure environments. This strength ensures that the steel can maintain its structural integrity and not buckle or collapse under the immense force. Furthermore, special steel is highly resistant to corrosion and oxidation, even at high temperatures. This resistance is crucial in high-temperature environments where the presence of hot gases, steam, or caustic chemicals can cause regular steel to degrade rapidly. Special steel's resistance to corrosion and oxidation ensures its longevity and reliability, making it an ideal choice for applications in such challenging conditions. Additionally, special steel exhibits excellent heat resistance. It can withstand extreme temperatures without losing its mechanical properties, such as strength and hardness. This characteristic is crucial in high-temperature environments where regular steel would weaken, soften, or even melt. Special steel's ability to maintain its structural stability even in extreme heat ensures the safety and reliability of equipment and structures operating in such conditions. Moreover, special steel is known for its excellent thermal conductivity. This property allows it to efficiently transfer heat away from the high-temperature environment, preventing localized hotspots and thermal stress. By effectively dissipating heat, special steel ensures the overall stability and performance of equipment and structures under high-pressure and high-temperature conditions. In summary, special steel performs exceptionally well in high-pressure and high-temperature environments due to its high strength, resistance to corrosion and oxidation, heat resistance, and excellent thermal conductivity. These properties make special steel a reliable and durable material for various applications, including power generation, oil and gas exploration, aerospace engineering, and many more.

- Q: What are the different types of corrosion-resistant steel?

- There are several types of corrosion-resistant steel, including stainless steel, galvanized steel, weathering steel, and nickel alloys. Each of these types has specific properties that make them resistant to corrosion in various environments and applications.

- Q: What are the different methods of surface thermal spraying for special steel?

- There are various techniques available for surface thermal spraying on special steel. These techniques consist of: 1. Flame spraying: This method involves melting the coating material using a flame or oxy-fuel source, and then spraying it onto the special steel surface. It is commonly utilized for applying coatings like zinc, aluminum, or their alloys. 2. Arc spraying: In arc spraying, the coating material is melted using an electric arc and then propelled onto the special steel surface using compressed air. This technique is often employed for applying coatings such as stainless steel, nickel alloys, or copper. 3. Plasma spraying: Plasma spraying employs a plasma torch to heat and melt the coating material, which is then propelled onto the special steel surface. It is especially effective for applying coatings with high melting points like ceramic or metallic materials. 4. High-velocity oxy-fuel (HVOF) spraying: HVOF spraying uses a high-pressure combustion process to propel the coating material onto the special steel surface. This technique produces coatings with high bond strength and density, making it suitable for applications that require wear resistance or corrosion protection. 5. Detonation spraying: Detonation spraying involves a controlled detonation process to accelerate the coating material onto the special steel surface. It is often used for applying coatings such as tungsten carbide or other hard materials, providing excellent wear resistance. Each of these surface thermal spraying methods offers unique advantages and is chosen based on the specific requirements of the special steel application, including the desired coating material, thickness, and performance characteristics.

- Q: What are the main alloying elements used in special steel?

- The main alloying elements used in special steel can vary depending on the specific type of special steel, but common alloying elements include chromium, nickel, molybdenum, vanadium, and tungsten. These elements are added to enhance the steel's properties such as corrosion resistance, strength, hardness, and heat resistance.

- Q: What is the impact of impurities on the machinability of special steel?

- The machinability of special steel can be significantly affected by impurities. Impurities such as sulfur, phosphorus, and non-metallic inclusions have a negative impact on the performance and machinability of the material. Sulfur is often present in steel as an impurity, forming brittle compounds that reduce machinability. High levels of sulfur result in increased tool wear, poor surface finish, and decreased cutting tool life. Therefore, it is crucial to control sulfur content in special steel to ensure good machinability. Phosphorus is another impurity that adversely affects machinability. It forms hard and brittle compounds that lead to tool chipping, breakage, and poor chip control. High levels of phosphorus also cause reduced cutting tool life and surface finish. Non-metallic inclusions, such as oxides, sulfides, and silicates, are significant impurities in steel. These inclusions act as stress concentrators, resulting in increased tool wear and decreased machining quality. Large inclusions can even cause tool breakage, interrupting the machining process. Therefore, minimizing the presence of non-metallic inclusions is crucial for improving the machinability of special steel. In conclusion, impurities in special steel have a detrimental effect on its machinability. To ensure good machinability, it is important to carefully control and minimize the levels of impurities like sulfur, phosphorus, and non-metallic inclusions. This can be achieved through the careful selection of raw materials, refining processes, and implementing quality control measures during the manufacturing of special steel.

- Q: How is special steel used in the chemical industry?

- Special steel is used in the chemical industry for various applications due to its exceptional corrosion resistance, high temperature strength, and durability. It is commonly used to manufacture equipment such as pressure vessels, storage tanks, pipelines, and reactors that handle corrosive substances or operate under extreme conditions. Additionally, special steel alloys are utilized in the production of catalysts, valves, and pumps, ensuring reliable and efficient performance in chemical processes.

- Q: What are the applications of high-speed steel?

- High-speed steel has various applications due to its exceptional properties. It is commonly used in the manufacturing of cutting tools such as drills, saw blades, milling cutters, and taps. Its high hardness and heat resistance make it suitable for machining operations on materials like steel, cast iron, and non-ferrous alloys. Additionally, high-speed steel is also used in the production of power tool bits, punches, and dies, where its wear resistance and toughness are advantageous.

- Q: How does the cost of special steel compare to regular steel?

- Compared to regular steel, special steel generally has a higher cost. Special steel is designed and produced specifically to possess exceptional properties and characteristics that regular steel lacks. It goes through additional processes, such as alloying, heat treatment, or specialized manufacturing techniques, to enhance its strength, durability, corrosion resistance, and other desirable features. These additional production steps contribute to the overall increased cost of special steel. On the contrary, regular steel is more easily obtainable and produced on a larger scale. It is commonly used for general purposes and applications where high-performance qualities are not necessary. Regular steel is relatively cheaper due to its lower production costs and wider availability in the market. However, it is important to consider that the cost comparison between special steel and regular steel can vary based on several factors, including the specific type of steel, the quantity being purchased, market conditions, and any additional customization required. Therefore, it is advisable to consult steel suppliers or specialists for accurate pricing information tailored to specific requirements.

- Q: What are the different high-pressure grades of special steel?

- There exist several distinct varieties of special steel that are designed to withstand high pressures, each possessing its own unique characteristics and uses. Some frequently employed high-pressure grades of special steel encompass the following: 1. 4130 steel: This particular grade of steel is renowned for its exceptional strength, toughness, and resistance to heat. It finds considerable application in the fabrication of high-pressure tubing and components for the oil and gas industry. 2. 4340 steel: Distinguished by its extraordinary strength and toughness, this grade of steel is commonly utilized in the production of critical components like high-pressure valves, gears, and other crucial parts in industries such as aerospace, defense, and automotive. 3. 316 stainless steel: Highly resistant to corrosion and boasting excellent high-temperature properties, this stainless steel grade is frequently employed in high-pressure scenarios like pipelines, heat exchangers, and pressure vessels within the chemical and petrochemical industries. 4. 17-4 PH stainless steel: Offering a combination of high strength, superb corrosion resistance, and good toughness, this stainless steel grade often finds application in high-pressure pump components, turbine blades, and other vital parts within industries like power generation and aerospace. 5. F22 steel: Classified as a low-alloy steel with remarkable high-temperature strength and exceptional resistance to creep, this grade of steel is commonly used in high-pressure and high-temperature environments such as boilers, pressure vessels, and piping systems found in power plants and refineries. The aforementioned examples represent just a small selection of the available high-pressure grades of special steel. The appropriate grade choice is contingent upon the specific requirements of the application, encompassing factors such as pressure, temperature, corrosion resistance, and mechanical properties.

Send your message to us

Grade SAE 4140 Steel Price_Steel Round Bar Dimension

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords