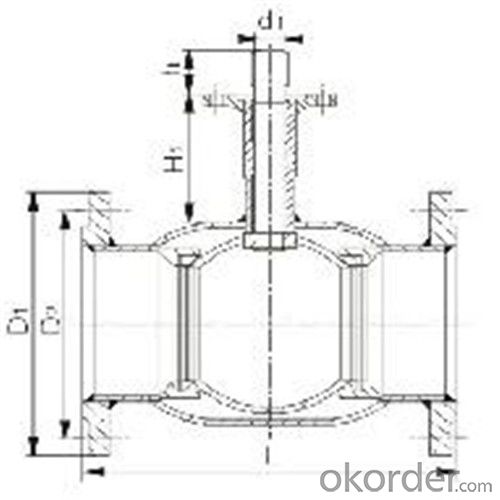

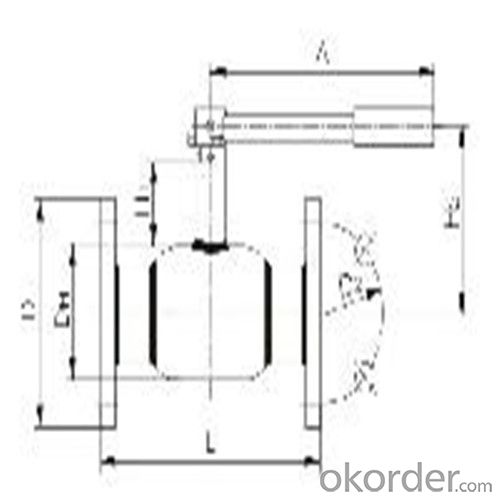

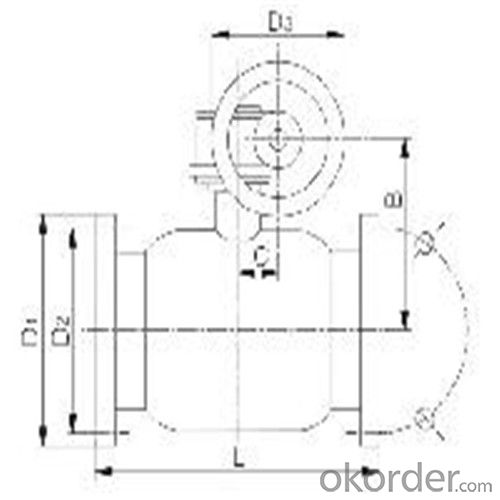

Ball Valve For Heating SupplyDN 150 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ball Valve For Heating Supply

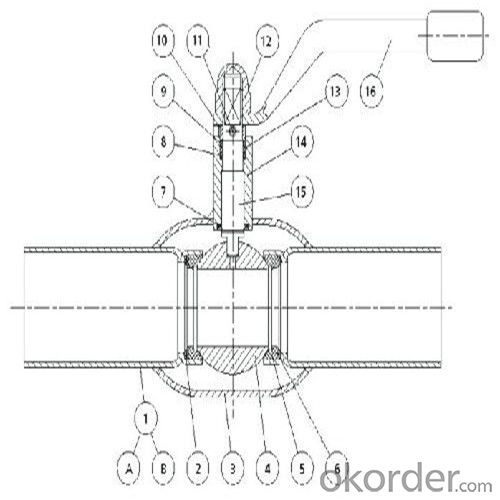

Product Description of Ball valve for heating supply:

Technical introduction

★The ball valve is designed as fully welded structure,which can prevent the leakage of medium.

★The valve seat is floating and spring-loade.The seal is made of soft seal materials of PTFE+20%C and Viton B.The seat is tightly abutted against the ball surface by the pressure of a spring,so that even if the media is in low pressure,a reliable sealing can be assured for the ball valve.Double piston effect and double seal(two-seal seat)are adopted in specially designed valve seat to realize double sealing,which makes the tightness of the ball valve more advantageous and the operation easier.

★A floating ball is adopted for DN15-DN200,and a stem and trunnion ball is adopted for DN200 and above,which can ensure the accurate position of different size ball.In other words,the sealing performance,low torque valve and operability can be guaranteed.

★The sealing of the stem is fulfilled by two replaceable O-rings and packing consisting of PTEE+20%C or flexible graphite,as the packing seal material,is fire proof effect,and is specially suitable for fuel gas systems.

★The materials used for the valve body and pipelines are the same(carbon steel or SS steel),valve body and stem adopt SS steel and the packing adopts PTEE+20%C which is corrosion-resistance or flexible graphite.

Design Features of Ball valve for heating supply:

Features and Applications

Raymond's fully welded ball valve for heating supplyand Fuel Gas systemare used to control the flow at fully open or closed position,not regulate the flow.Only special types of ball valves can realize the flow regulation.Therefore,our welded ball valves can satisfy the requirements of heating systems,e.g:

★Main pipelines of heating equipment

★Cross channels of heating pipes

★Heat exchanger station and any long distance operating station,e.g:

For the transmission of hot water and two kinds of mixed media(water,air or natural gas),limited to Max.4.0MPa and 200°C.

For the transmission of natural gas and one medium,from -30°C to 60°C,and even up to 150°C using specially designed ball valves.

★Coal gas pipelines,trunk and the branch supply lines.

Standard of Ball valve for heating supply:

Actuator | Gear Handwheel customize |

Connection | Flange SW Weld customize |

Medium | Gas Natural gas Water customize |

Medium Temperature | <200< span="">℃ customize |

Application Fields | Electricity Medical Petrochemical customize |

Connection Standard | EN 1092-1 EN 12627 ISO 7-1 customize |

FAQ of Ball valve for heating supply:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: I was considering making a ball valve PVC air rifle or something of the sort using a PVC air canister and a hand pump, but I wanted to know about it, last year I made one that was air tight but air leaked out of the top of the pump which really annoyed me, I looked further onto the it and found out that there was a Bike Tyre valve, What does it do? Does it let air flow in but stop it from coming out? and where would I find some good designs as well as the items needed to make it? And don't bother answering 'Buy an air soft gun' because Australia does not retail those.

- hi there in canada , at any big truck tire repair place they have tire valves that are like bunker fittings, that is to say a valve that has a threaded bottom end with nuts and rubber washers, you would drill the appropriate size hole in the pipe and put the valve through and tighten the nuts up against the washers making an air tight seal, that should work for you if they have them in au, good luck

- Q: Need some info. Ok, four valves per cylinder is better than two valves per cylinder. Fine, why did Ford REVERT to only 3 valves (my guess is to save cost SOHC)? Audi and VW are using five valves per cylinder on some cars, does this offer any advantage over a four valve engine? Maserati even experimented with a six valve per cylinder!!!! (see link) http://www.maserati-alfieri .uk/alfier... but abandoned it (my guess is cost again?) Why are we stuck at four valves or would more valves actually render more horsepower? Pop some ideas best answer to reasonable answer...

- Think of an engine as an air pump - obviously, we want the least amount of restriction for the incoming air and also the least amount for exhausting the compressed air. The ideal situation would be to remove the head during the intake stroke and put it back on during the compression stroke, but, obviously, this isn't possible. On a naturally aspirated engine, the intake is the most critical because the air is moved only by a relatively small difference in pressures. The exhaust stroke, on the other hand, is aided greatly by the super heated temperature and rapid expansion of the gasses. Two intake and one exhaust valve seems to be the most practical and efficient solution - adding more vales means smaller valves and an increase in the overall complexity. I seriously doubt that Maserati ever abandoned ANY automotive idea due to cost restraints. It's far more likely that adding more valves than three or four simply resulted in diminishing returns. Sometimes the allure of a new buzz phrase is nothing more than a marketing ploy - a 16 valve, DOHC, four cylinder engine, for example, is a pretty impressive resume for an engine, regardless of whether it actually is the optimum performance set up or not.

- Q: Hi, i bought an xr250r 2002 model. I rebuilt the engine and put in new exhaust valves. After i did this proper compression in the motor came back and it wasnt blowing smoke anymore. I took it for a 'run-in' ride, and noticed that the engine was quite noisy. I guessed it was the valves needing adjusting. I got numbers for the valve clearences which were: .004 of in inch for the exhaust valves and .005 of an inch for the air intake. Now i have done this the compression in the bike is enormous, it is barely possible to kick over, and the motor is very noisy, there is a loud ticking noise which im guessing is still the valves. Is all this normal considering i have just rebuilt the engine, put in new valves and hardly ridden (one 50km ride)? I would like to keep riding it to run it better to see if the motor loosens up, but im scared to ride it as it is. Any advice would be greatly appreciated.

- I think you should check the other end of the engine too. Remove the sump and make sure the big ends have no play. Then you are good to go. Replacing the big end shells in good time is easy but if left too long then the engine is a right off. Possible also a transmission bearing is dying which you can spot at the same time.

- Q: I noticed when I pulled my pcv valve off the valve cover the entire guts were missing. what would this make the car run like?

- Will run at higher idle and suck all the oil out of engine, then run bad until engine locks up and exhaust would be smoking like crazy. plus other things. Suggest you replace and check oil level.

- Q: What are the benefits of changing new cylinder heads and exhaust valves in the Main engine of the vessel? I am now studying a vessel which has a problem with their main engine. Frequent repair of cylinder heads (they usually weld it) and exhaust valves are the ones they do. I need to further give the benefits to be submitted to the vessel's management for them to buy new cylinder heads and exhaust valves as a replacement for the welded ones.

- It sounds to me like this ship has an ongoing exhaust problem (maybe an obstruction of the flow) Or a low volume of cooling water (look at the water pumps) About the only reason to weld a head would be because of a crack and the most likely reason for a crack is over heating likewise the burned valves! Assuming that the engine was assembled correctly What else would cause the over heating except one of the above! Before you put new expensive heads and valves on this thing check out the over heating ( just because the Gage never shows hot dose not mean that it isn't! If the welding and the valve replacement was done correctly then there may be no benefit at all in buying new ones a compression test would tell,but a REAL LARGE benefit in finding out WHY this would happen especially more then ounce !

- Q: Ok, so I was just wondering, do you have to have a turbo to get blow-off valves? Also, do you have to have a manual? And are there any other requirements?

- I'm a girl.....you don't have to have a turbo, any type of fast car will get you blown off.

- Q: recently changed head gasket. could valves tap from the push rods being mixed up? they all seemed to be the same size and i know the other side was exactly the same when put back together but this side is mixed up. could this make the valves go crazy? and i need to replace my water pump because its getting very hot and no coolant moving. and everything is smokin up, took off oil cap and it was steaming. would that have anything to do with making the valves tap?

- You have multiple problems all at once! Also you didn't say whether it has hydraulic or mechanical valves, adjustable or non adjustable, -- some have discs that are changed out to make proper clearance (Volkswagen for example on rabbit engines)! So lets start with valve adjustments. Hydraulic lifters could be flat and not pumped up yet (depending on how long engine has run)! Or need adjusting etc! Next problem is overheating, -- did you remove the thermostat to see if water moves through the system? This could be cause of blown head gasket in first place? It is not impossible that water pump could be bad, -- but it is not common, --- if it is turning, it would have to have vanes broken off, or split impeller spinning on shaft to not pump! And this does not happen often! There is no such word as impossible with machines! ................. Steam from oil cap could just be water evaporating out of oil, - and usually with blown head gasket, - water gets into oil pan too! ........ But this part should not have anything to do with noisy valves! Is this an engine with belt driven timing system, or chain driven one with overhead cam? Did you for sure get camshaft timing right, -- if a tooth or two off, it may run, but possibly pistons nicking valves? Also bad timing may make engine run hotter than it is supposed to! If this is a for or chev V-8, (and some V-6es) you can adjust rocker arm lash to get proper clearance. Get hold of a manual for procedure, -- you can look up in auto repair manual in library, - if nothing else!

- Q: My 3rd valve keeps getting stuck when i play it, i have valve oil, but its just not working, help please

- There are several possibilities. You may have buildup on either the valve or the casing. Cleaning it thoroughly should normally remove it, but every once in a Blue Moon it pays to take it in and have it professionally cleaned. They can inspect it at the same time and tell you if you have a bend or a ding in the casing. Sometimes they are really hard to spot, especially if they are hidden in one of the crevices of the detail work. A really good repair person can stick a scope down there and tell you if you have some kind of blockage in just a few minutes. The only way to really clean inside the casing yourself is to get a good bottle brush that fits inside with just a little bit of resistance. You should really get someone to show you how to do it the first time because you don't want to go scraping up the insides. There is one other possibility that is kind of rare. Sometimes you get some gunk up under the valve button and it sticks when you push it down. You should normally be able to see this just by looking underneath however. Best of luck and I hope you find your sticking point and are able to set it free.

- Q: hi i want to now what a BOV (blow off valve) i no what it does but i dont no the instalation process what pipes and stuff are invalved and were does it go next to the turbo of air intake

- Most are designed to install on the intake/turbo piping. They're for the release of pressure surges to keep the turbo safe. Most stock bovs are not capable of raised boost which is why many buy aftermarket ones.

- Q: anyone know .. if the 5.7L Hemi 2003 has a egr valve?

- it might be on the passenger side on the valve cover

Send your message to us

Ball Valve For Heating SupplyDN 150 mm high-performance

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 1000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords